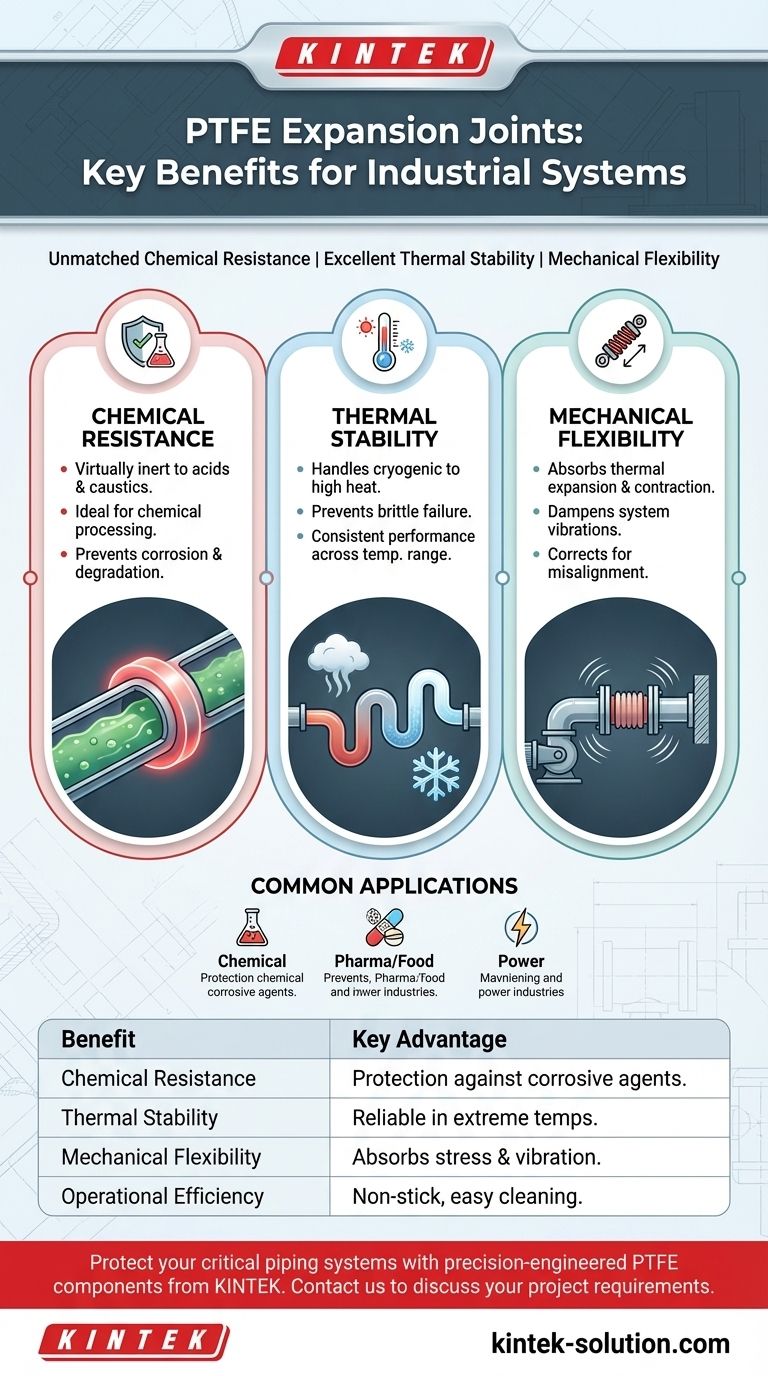

In short, PTFE expansion joints provide three primary benefits: unparalleled chemical resistance, excellent thermal stability, and the mechanical flexibility to absorb movement and vibration. This unique combination protects the integrity of industrial piping systems by mitigating the primary sources of stress—corrosion, temperature fluctuations, and physical strain—thereby enhancing safety, reducing downtime, and extending equipment lifespan.

Industrial piping is under constant assault from corrosive media, thermal stress, and mechanical vibration. PTFE expansion joints serve as a critical defense, acting as a flexible, inert barrier that absorbs these destructive forces to preserve the entire system's reliability and longevity.

The Core Functions of a PTFE Expansion Joint

A PTFE expansion joint, or compensator, is engineered to introduce flexibility at critical points within a rigid piping system. This flexibility serves several distinct protective functions.

Absorbing Thermal Expansion and Contraction

Piping systems expand and contract as the temperature of the fluid they carry changes. This movement creates immense stress on fixed points like pumps, vessels, and valves. A PTFE expansion joint compresses and extends to safely absorb this thermal growth, preventing pipe buckling or catastrophic failure.

Dampening System Vibrations

Mechanical equipment like pumps, compressors, and engines generates constant vibration. These vibrations travel through the pipeline, causing noise, metal fatigue, and loosening connections. An expansion joint acts as a shock absorber, isolating vibrations and protecting sensitive equipment down the line.

Correcting for Misalignment

Perfect pipe alignment during installation is difficult and often impractical. A PTFE expansion joint can compensate for initial lateral, angular, or axial misalignment, simplifying construction and preventing the constant stress that misaligned pipes exert on connected equipment.

The Material Advantage: Why PTFE Excels

The effectiveness of an expansion joint is defined by its material properties. Polytetrafluoroethylene (PTFE) offers a combination of characteristics that make it uniquely suited for the most demanding industrial environments.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals, acids, and caustics. This makes it the ideal choice for systems in chemical processing plants, where aggressive media would quickly corrode metal or degrade other elastomers.

Wide Thermal Stability

These components operate reliably across an exceptionally broad temperature range. This allows them to handle everything from cryogenic fluids to high-temperature steam without becoming brittle or losing structural integrity.

Operational Efficiency

The material has an extremely low coefficient of friction, creating a non-stick surface. This quality is vital in food, beverage, and pharmaceutical applications where it prevents material buildup, ensures product purity, and simplifies cleaning.

Durability and Longevity

The combination of chemical and thermal resilience means PTFE components do not degrade easily. This leads to a longer service life, reduced replacement frequency, and lower long-term maintenance costs compared to less robust materials.

Understanding the Trade-offs

While highly effective, PTFE expansion joints are not a universal solution. Their primary limitation compared to metal expansion joints is a lower pressure rating. The inherent flexibility of PTFE means it is not suited for extremely high-pressure applications where a metallic bellow would be required.

Furthermore, proper selection and installation are critical. Failing to account for the precise combination of temperature, pressure, and chemical exposure can lead to premature failure. The component must be specified correctly for the unique demands of the system to realize its full benefits.

Common Applications Across Industries

The unique properties of PTFE make these expansion joints indispensable in several key sectors.

Chemical Processing

In plants handling aggressive chemicals, PTFE-lined pipes and expansion joints are standard. They safeguard equipment from corrosion, ensuring both operational safety and workflow continuity.

Pharmaceuticals and Food Production

The non-toxic, FDA-approved nature of PTFE makes it essential for maintaining hygiene and preventing contamination. Its non-stick surface ensures product purity in sterile environments.

Power Generation

Power plants rely on PTFE expansion joints to withstand high-pressure steam and manage the significant thermal fluctuations common in their piping systems, protecting critical infrastructure from cyclic fatigue.

Making the Right Choice for Your System

Selecting the right component requires aligning its capabilities with your primary operational goal.

- If your primary focus is handling aggressive chemicals: A PTFE expansion joint is the definitive choice for preventing corrosion and ensuring system longevity.

- If your primary focus is maintaining product purity: The non-stick, FDA-approved properties of PTFE are essential for pharmaceutical or food-grade applications.

- If your primary focus is managing vibration and thermal stress in moderate-pressure systems: PTFE provides a durable and cost-effective solution for protecting mechanical equipment.

Ultimately, integrating PTFE expansion joints is a strategic decision to build a more resilient, safe, and efficient industrial system.

Summary Table:

| Benefit | Key Advantage |

|---|---|

| Chemical Resistance | Unmatched protection against corrosive acids, caustics, and industrial chemicals. |

| Thermal Stability | Reliable performance across a wide temperature range, from cryogenic to high heat. |

| Mechanical Flexibility | Absorbs vibration, thermal expansion, and misalignment to prevent equipment stress. |

| Operational Efficiency | Non-stick surface prevents buildup, ensures purity, and simplifies cleaning in sensitive industries. |

Protect your critical piping systems with precision-engineered PTFE components from KINTEK.

Our PTFE expansion joints are custom-fabricated to meet the exact demands of your application—whether in semiconductor, medical, laboratory, or industrial settings. We prioritize precision manufacturing to deliver components that enhance safety, reduce maintenance costs, and extend equipment lifespan.

Contact us today to discuss your project requirements, from prototypes to high-volume orders, and see how KINTEK’s expertise can solve your toughest piping challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability