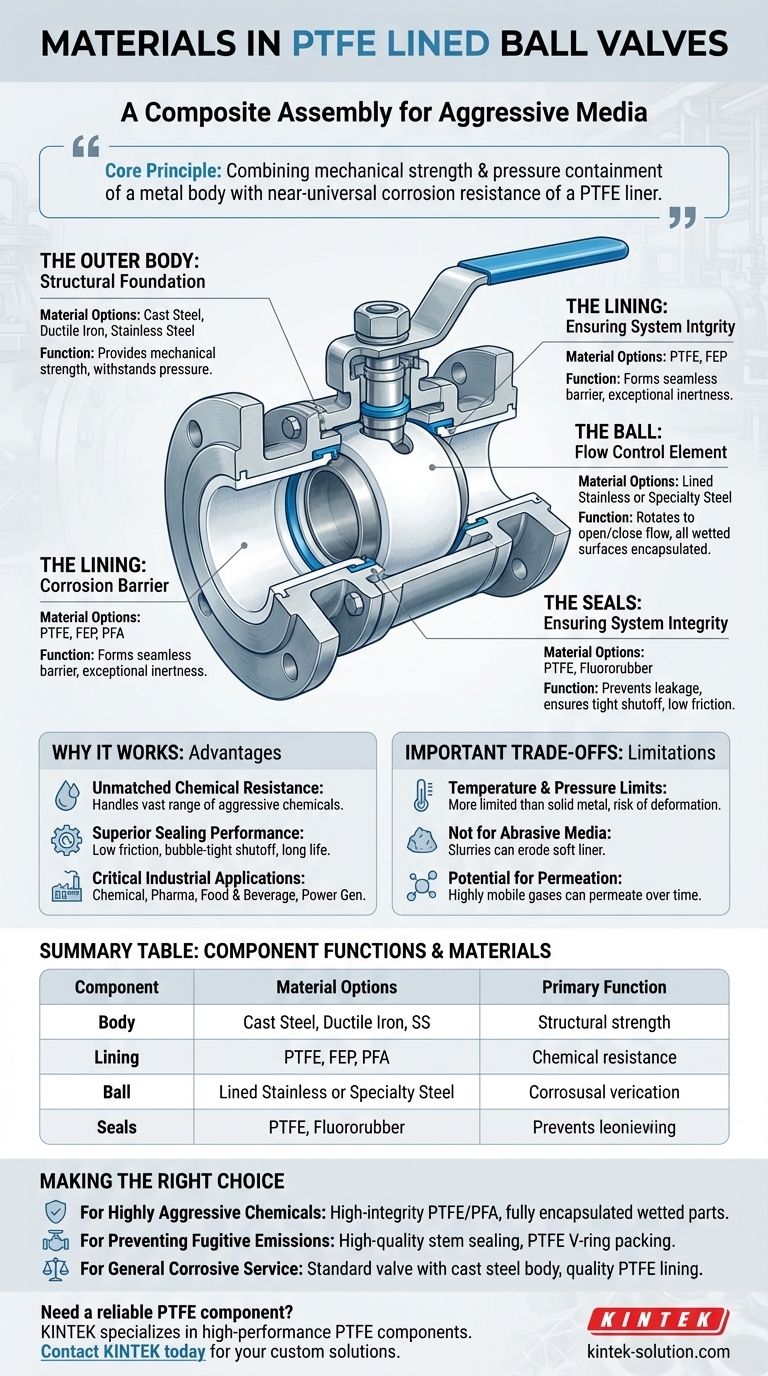

A PTFE lined ball valve is a composite assembly where each material is chosen for a specific function. The primary components include a structural body of cast steel, ductile iron, or stainless steel; a chemically inert lining of Polytetrafluoroethylene (PTFE); a ball typically made of lined stainless or specialty steel; and seals made from PTFE or fluororubber.

The core principle of a PTFE lined ball valve is to combine the mechanical strength and pressure containment of a metal body with the near-universal corrosion resistance of a PTFE liner, creating a cost-effective solution for handling aggressive chemical media.

Deconstructing the PTFE Lined Ball Valve

To understand why these valves are so effective, we must look at the specific role each material plays in its construction. The design isolates the structural components from the corrosive process fluid.

The Outer Body: The Structural Foundation

The valve body provides the mechanical strength to withstand pipeline pressure and stress. Its material does not contact the process fluid.

Common body materials include cast steel and ductile iron for general industrial applications, offering excellent strength and durability at a reasonable cost. For environments with external corrosion concerns, a stainless steel body is often specified.

The Lining: The Corrosion Barrier

The lining is the most critical component for chemical resistance. It forms a continuous, seamless barrier on all wetted surfaces of the valve.

PTFE is the most common lining material due to its exceptional inertness to nearly all acids, bases, salts, and organic solvents. Related fluoroplastics like FEP or PFA are also used to ensure a uniform lining that resists blowout or collapse under vacuum.

The Ball: The Flow Control Element

The ball is the central element that rotates to open or close the flow path. Like the body, all its wetted surfaces are fully encapsulated.

The core of the ball is typically made from stainless steel for strength and rigidity. This metal core is then completely lined with a thick layer of PTFE, ensuring the process media only ever contacts the inert fluoroplastic.

The Seals: Ensuring System Integrity

Seals are critical for preventing both internal and external leakage. The valve's stem packing and seat rings are designed to create a tight shutoff.

Materials like PTFE and fluororubber are used for these components. Their chemical resistance and low-friction properties ensure a reliable, long-lasting seal without compromising the valve's ease of operation.

The "Why" Behind the Design: Performance in Harsh Environments

The specific combination of a strong outer body and a non-reactive inner lining gives these valves distinct advantages in demanding industries. The design directly addresses the challenge of safely controlling and shutting off corrosive fluids.

Unmatched Chemical Resistance

The PTFE lining is the key. It allows a single valve type to handle a vast range of aggressive chemicals, simplifying inventory and reducing the risk of material incompatibility that could lead to catastrophic failure.

Superior Sealing Performance

PTFE's exceptionally low coefficient of friction allows the ball to turn smoothly with minimal torque. This reduces wear on the seats and stem seals, contributing to a bubble-tight shutoff and a long service life.

Critical Industrial Applications

Because of these features, PTFE lined ball valves are indispensable in industries where fluid purity and corrosion control are paramount.

You will find them extensively used in chemical processing, pharmaceutical manufacturing, food and beverage production, and power generation plants for any pipeline transporting acids, alkalis, or corrosive solvents.

Understanding the Trade-offs

While highly effective, PTFE lined valves have specific limitations that are crucial to understand for proper application. They are not a universal solution for every valving need.

Temperature and Pressure Limits

PTFE has a more limited operating temperature and pressure range than a solid metal alloy valve. Exceeding these manufacturer-specified limits can cause the liner to deform, leading to valve failure.

Not for Abrasive Media

The primary strength of PTFE is chemical resistance, not abrasion resistance. Slurries or fluids containing hard particulates can quickly erode the soft liner, compromising the valve's integrity.

Potential for Permeation

While PTFE is a robust barrier, highly mobile molecules like certain gases can slowly permeate through the liner over extended periods. This is a critical consideration in high-purity or specific hazardous gas applications.

Making the Right Choice for Your System

Selecting the correct valve requires matching its material construction to your specific operational goal.

- If your primary focus is handling highly aggressive chemicals: Ensure the valve has a thick, high-integrity PTFE or PFA lining and that all wetted parts, including the ball and stem, are fully encapsulated.

- If your primary focus is preventing fugitive emissions: Prioritize a valve with a high-quality stem sealing system, often utilizing PTFE V-ring packing, to ensure external tightness.

- If your primary focus is general corrosive service: A standard valve with a cast steel body and a quality PTFE lining provides the most effective balance of performance and cost.

Ultimately, understanding the role of each material empowers you to select a valve that ensures the safety, reliability, and longevity of your fluid handling system.

Summary Table:

| Component | Material Options | Primary Function |

|---|---|---|

| Body | Cast Steel, Ductile Iron, Stainless Steel | Structural strength and pressure containment |

| Lining | PTFE, FEP, PFA | Chemical resistance barrier for wetted surfaces |

| Ball | PTFE-Lined Stainless Steel | Flow control, isolated from process media |

| Seals | PTFE, Fluororubber | Bubble-tight shutoff and stem packing |

Need a reliable PTFE component for your demanding application?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom seals, liners, and labware. Our expertise ensures your equipment—whether for semiconductor, medical, laboratory, or industrial use—is built to handle aggressive chemicals and maintain system integrity.

We offer custom fabrication from prototypes to high-volume orders, prioritizing the exact material properties and design specifications your operation requires.

Contact KINTEK today to discuss your project and discover how our PTFE solutions can enhance the safety and longevity of your fluid handling systems.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability