Unlike conventional plastics or metals, Teflon's uniqueness in CNC machining stems from a paradoxical combination of properties. Its extreme softness, low friction, and poor heat conductivity make it behave less like a rigid material that is cut and more like a dense, malleable substance that must be carefully managed to prevent smearing, deformation, and thermal damage.

The core challenge of machining Teflon (PTFE) is not about power, but control. Success requires treating the material with finesse, using exceptionally sharp tools and precise strategies to manage its inherent softness and inability to dissipate heat, which can otherwise ruin tolerances and surface finish.

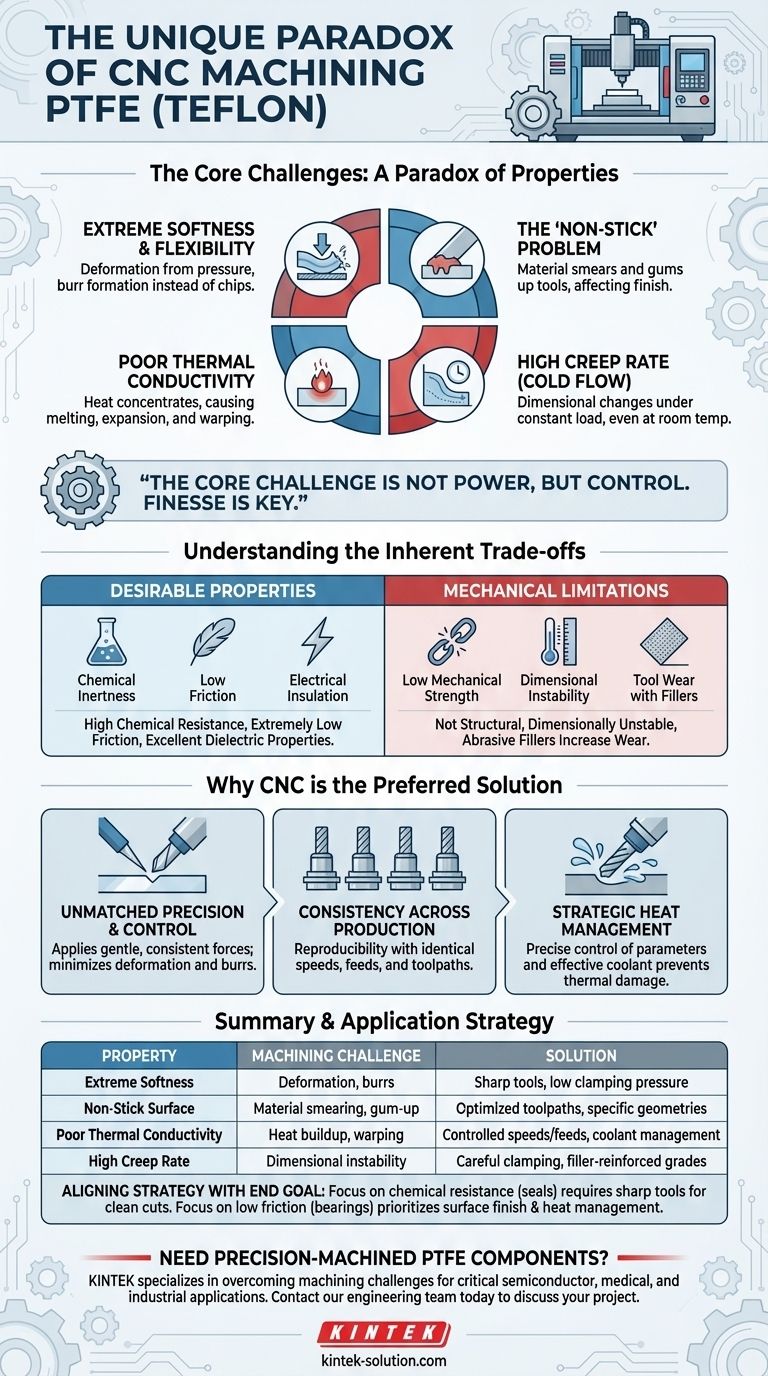

The Core Challenges of Machining PTFE

Polytetrafluoroethylene (PTFE), or Teflon, presents a set of properties that are highly desirable in a finished product but create distinct obstacles during the machining process. Understanding these is the first step toward a successful outcome.

Extreme Softness and Flexibility

PTFE is an exceptionally soft material. This means it can easily be compressed or deformed by excessive clamping pressure in a CNC machine, leading to inaccurate dimensions once the part is released.

This softness also means the material tends to form burrs during cutting rather than producing a clean chip. These burrs must often be removed in a secondary finishing process.

The "Non-Stick" Problem

The same low-friction, non-stick property that makes Teflon useful can cause it to smear or "gum up" on cutting tools. Instead of shearing away cleanly, the material can build up on the tool edge, degrading performance and affecting the surface finish.

Poor Thermal Conductivity

Teflon is an excellent thermal insulator. During machining, the heat generated by friction has nowhere to go; it concentrates at the cutting point instead of dissipating through the material or the tool.

This localized heat buildup can cause the material to melt, expand, or warp, compromising the dimensional accuracy of the final component.

High Creep Rate (Cold Flow)

PTFE has a high tendency to "creep," meaning it will slowly deform over time when subjected to a constant load, even at room temperature.

This impacts both the machining process (clamping pressure can cause deformation) and the final part's long-term stability in applications where it will be under constant mechanical stress.

Understanding the Inherent Trade-offs

Choosing PTFE for its benefits, such as chemical inertness and low friction, requires accepting its significant mechanical limitations. These trade-offs are critical to consider during the design phase.

Low Mechanical Strength

PTFE is not a structural material. It deforms easily under load and has low tensile strength compared to other engineering plastics. It is unsuitable for applications requiring high rigidity or load-bearing capacity.

Dimensional Instability

The combination of a high coefficient of thermal expansion and its tendency to creep makes PTFE dimensionally unstable. A part machined to tight tolerances at one temperature may be out of spec at another, a critical factor for precision applications.

Managing Tool Wear

While PTFE itself is soft, some grades are filled with abrasive materials like glass or carbon to improve mechanical properties. These fillers can cause rapid tool wear, requiring harder tool materials like carbide and specific cutting geometries.

Why CNC is the Preferred Method for PTFE

The very challenges that make PTFE difficult to machine are why CNC (Computer Numerical Control) is the ideal solution. It provides the high level of control necessary to counteract the material's problematic properties.

Unmatched Precision and Control

CNC machines can apply gentle, consistent cutting forces with exceptionally sharp tools. This minimizes the material deformation and burr formation common with manual processes.

Consistency Across Production Runs

Once a process is dialed in, CNC machining ensures every part is produced with the same speeds, feeds, and toolpaths. This reproducibility is vital for a material as sensitive to process variables as PTFE.

Strategic Heat Management

CNC programming allows for precise control over cutting speeds and feed rates, which are the primary levers for managing heat generation. Paired with effective coolant application, a CNC process can prevent the thermal damage that ruins PTFE parts.

Making the Right Choice for Your Application

Selecting and machining PTFE successfully depends entirely on aligning your strategy with the material's behavior and your end goal.

- If your primary focus is chemical resistance for seals or gaskets: Leverage its inertness but use extremely sharp, single-point tools to achieve a clean-cut surface free of burrs that could compromise sealing.

- If your primary focus is low friction for bearings or insulators: Prioritize surface finish and heat management to maintain dimensional stability, and choose a PTFE grade with fillers if you need improved wear resistance and lower creep.

- If your primary focus is a complex geometry: Acknowledge that success depends on a CNC process designed to minimize clamping pressure, manage thermal expansion, and utilize specialized tooling like parabolic drills for clean holes.

By understanding and respecting its unique properties, you can transform PTFE's machining challenges into a significant engineering advantage.

Summary Table:

| Property | Machining Challenge | Solution |

|---|---|---|

| Extreme Softness | Deformation, burrs | Sharp tools, low clamping pressure |

| Non-Stick Surface | Material smearing, gum-up | Optimized toolpaths, specific geometries |

| Poor Thermal Conductivity | Heat buildup, warping | Controlled speeds/feeds, coolant management |

| High Creep Rate | Dimensional instability | Careful clamping, filler-reinforced grades |

Need precision-machined PTFE components that meet your exact specifications? At KINTEK, we specialize in overcoming the unique challenges of machining Teflon/PTFE for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures your parts have the dimensional stability, surface finish, and chemical resistance required for critical applications.

Contact our engineering team today to discuss your project and benefit from our precision production capabilities.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- In which industries are PTFE gland packings commonly used? For Purity, Chemical Resistance & Reliability

- Why is Teflon used in hoses? Ensuring Unmatched Reliability in Extreme Conditions

- How do ceramic-filled PTFE laminates differ from standard PTFE laminates? Superior Signal Integrity for RF/Microwave

- Why is PTFE's low friction property beneficial in manufacturing? To Reduce Wear, Downtime & Energy Costs

- What industries are PTFE gaskets particularly suitable for? Ideal for Chemical, Pharma, and Food Processing

- How does PTFE's low coefficient of friction affect its machining process? Balancing Clean Cuts with Material Distortion

- What are static applications and how are PTFE O-Rings used in them? Ensure Leak-Proof Seals in Demanding Environments

- What standards are available for PTFE gaskets? Selecting the Right Standard for Reliable Sealing