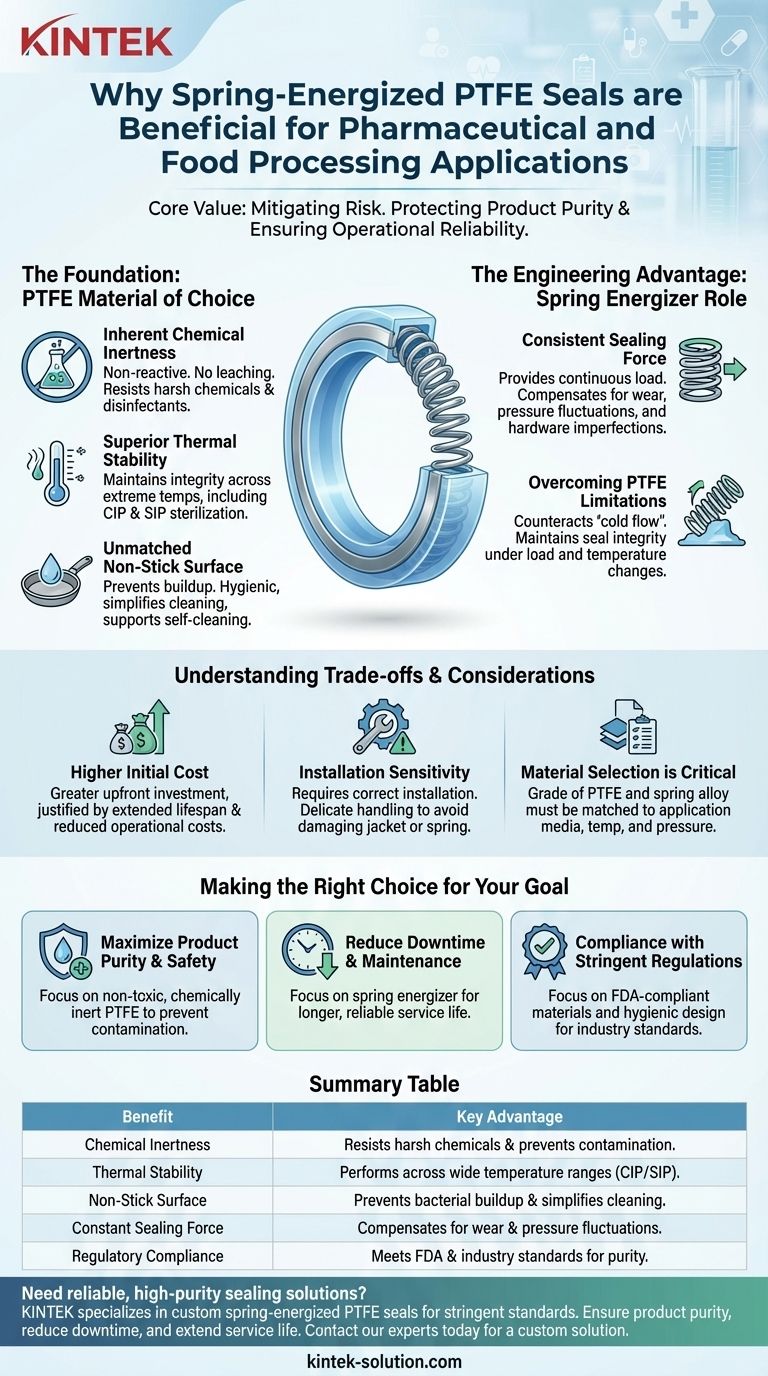

The fundamental benefits of spring-energized PTFE seals in pharmaceutical and food processing stem from a unique combination of material purity and mechanical reliability. The PTFE jacket is chemically inert, non-toxic, and features a non-stick surface, preventing product contamination and simplifying cleaning. The internal spring provides a constant, reliable sealing force that standard elastomer seals cannot match, ensuring performance across wide temperature ranges and pressure fluctuations.

The core value of these seals is their ability to mitigate risk. They simultaneously protect product purity to meet stringent regulatory standards while ensuring operational reliability to minimize costly downtime and maintenance cycles in sensitive environments.

The Foundation: Why PTFE is the Material of Choice

The effectiveness of the entire seal begins with the inherent properties of its primary material, Polytetrafluoroethylene (PTFE). These characteristics make it uniquely suited for environments where purity and safety are non-negotiable.

Inherent Chemical Inertness

PTFE is one of the most non-reactive materials known. It is virtually immune to degradation from process fluids, harsh cleaning agents, and disinfectants common in the pharmaceutical and food industries.

This chemical inertness ensures the seal will not leach unwanted substances into the product, preserving its purity and integrity. It also means the seal itself will not be compromised by aggressive sterilization protocols.

Superior Thermal Stability

Manufacturing processes in these sectors often involve extreme temperatures, from cryogenic applications to high-temperature sterilization like Clean-in-Place (CIP) and Steam-in-Place (SIP) systems.

PTFE maintains its structural integrity and sealing properties across this wide thermal range. This stability is critical for ensuring a consistent seal during repeated cycles of heating and cooling, which can cause other materials to fail.

Unmatched Non-Stick Surface

The surface of PTFE is naturally non-stick and non-adsorbent. This means that process media, from thick pastes to sticky syrups, do not adhere to the seal surface.

This property is vital for hygiene. It prevents the buildup of residual material that could harbor bacteria, significantly simplifies cleaning processes, and supports the self-cleaning of components in some applications.

The Engineering Advantage: The Role of the Spring Energizer

While PTFE provides the ideal contact surface, it has low elasticity. The internal spring is the engineering solution that turns a static material into a dynamic, high-performance seal.

Consistent Sealing Force

The spring provides a continuous, uniform load against the sealing surfaces. This ensures a tight seal even at low pressures, where an un-energized seal might fail.

This constant force also compensates for minor hardware imperfections, pressure fluctuations, and natural wear of the PTFE jacket over time, dramatically extending the seal's reliable service life.

Overcoming PTFE's Limitations

PTFE can be susceptible to "cold flow" or creep, especially under load and at higher temperatures. The spring energizer actively counteracts this tendency.

By constantly pushing the PTFE jacket outwards, the spring ensures that the sealing lip remains in contact with the hardware, maintaining seal integrity where a simple PTFE gasket might deform and leak.

Understanding the Trade-offs and Considerations

While highly effective, spring-energized PTFE seals are a specialized component, and their selection requires a clear understanding of certain factors.

Higher Initial Cost

These seals represent a greater upfront investment compared to standard elastomeric O-rings or simple gaskets. Their cost is justified by their extended lifespan and the reduced operational costs from less downtime and maintenance.

Installation Sensitivity

Proper performance depends on correct installation. The seal and its housing have specific design requirements, and care must be taken to avoid damaging the PTFE jacket or the spring during assembly.

Material Selection is Critical

Not all PTFE compounds or spring materials are equal. The specific grade of PTFE and the spring alloy (e.g., stainless steel, Elgiloy) must be carefully matched to the application's chemical media, temperature, and pressure to ensure optimal performance and compliance.

Making the Right Choice for Your Goal

Selecting the right sealing solution depends on balancing compliance, performance, and operational efficiency.

- If your primary focus is maximizing product purity and safety: The non-toxic, non-adsorbent, and chemically inert properties of PTFE are your greatest assets, directly preventing contamination.

- If your primary focus is reducing operational downtime and maintenance: The spring energizer's ability to compensate for wear and thermal cycles provides a significantly longer and more reliable service life than alternative seals.

- If your primary focus is compliance with stringent regulations: The combination of FDA-compliant materials and a design that promotes hygienic conditions makes these seals an ideal choice for meeting industry standards.

Ultimately, these seals are chosen because they provide a robust and dependable barrier in applications where failure is not an option.

Summary Table:

| Benefit | Key Advantage |

|---|---|

| Chemical Inertness | Resists harsh chemicals and prevents contamination |

| Thermal Stability | Performs across wide temperature ranges (CIP/SIP) |

| Non-Stick Surface | Prevents bacterial buildup and simplifies cleaning |

| Constant Sealing Force | Compensates for wear and pressure fluctuations |

| Regulatory Compliance | Meets FDA and industry standards for purity |

Need reliable, high-purity sealing solutions for your pharmaceutical or food processing equipment? KINTEK specializes in manufacturing precision PTFE components, including custom spring-energized seals designed to meet stringent regulatory standards. Our seals ensure product purity, reduce downtime, and extend service life in demanding environments. Contact our experts today to discuss your specific application requirements and get a custom solution that guarantees performance and compliance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications