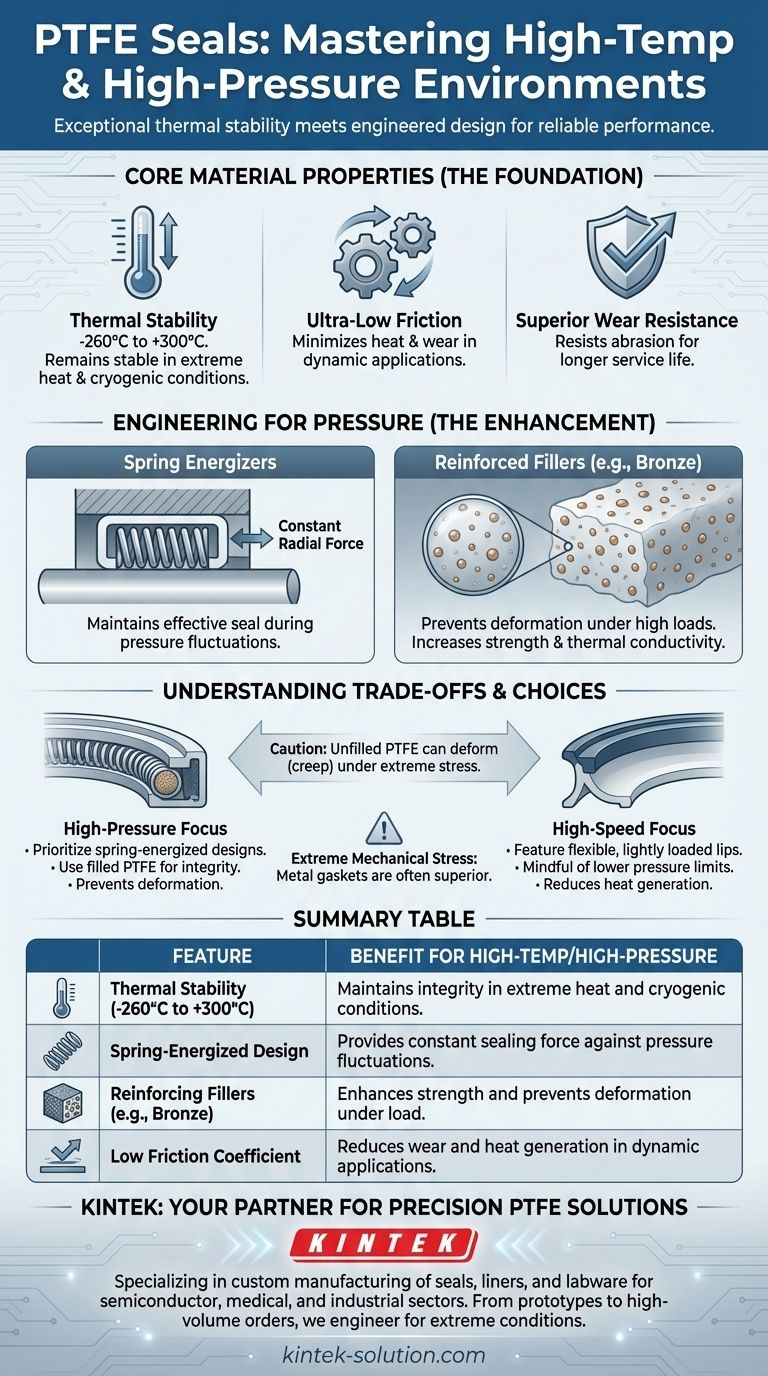

At its core, the suitability of Polytetrafluoroethylene (PTFE) for high-temperature and high-pressure environments stems from its exceptional thermal stability and a design that leverages mechanical assistance to maintain a constant sealing force. While its raw material properties provide the foundation, it is the engineering of the seal itself that truly unlocks its high-performance capabilities.

The key takeaway is that while pure PTFE offers an incredibly wide operating temperature range, its true effectiveness in high-pressure scenarios comes from strategic enhancements like spring-energizers and reinforcing fillers, which prevent deformation and ensure a consistent, reliable seal.

Unpacking PTFE's Core Properties

To understand why PTFE is chosen for demanding jobs, we must first look at the inherent characteristics of the material itself. These properties form the foundation upon which high-performance seals are built.

Exceptional Thermal Stability

PTFE can withstand an extremely broad range of temperatures, typically from -260°C to +300°C. This ensures that the seal material remains physically stable and operational in environments where other materials would become brittle or degrade.

Ultra-Low Friction

The material possesses an incredibly low coefficient of friction. This is critical in dynamic applications, as it minimizes heat generation from movement, reducing wear and preventing premature failure, especially at high surface speeds.

Superior Wear Resistance

PTFE's inherent durability means it resists abrasion and wear over time. This quality ensures a longer service life and reliable performance, even in applications with continuous or frequent motion.

Why Design and Composition Matter for Pressure

While the base material is impressive, it is not inherently perfect for high-pressure applications on its own. Specific design and compositional changes are what elevate a PTFE seal to a high-pressure solution.

The Role of Spring Energizers

Many high-pressure PTFE seals are spring-energized. A metallic spring inside the seal jacket exerts a constant radial force against the mating surface. This design ensures an effective seal is maintained even when system pressure fluctuates or is very low.

The Impact of Fillers

Pure PTFE can be prone to deformation under high loads. To counteract this, fillers are added. For example, bronze-filled PTFE offers enhanced thermal conductivity and strength, making it ideal for high-pressure hydraulic piston rings that experience frequent starts and stops.

Sealing Pressurized Media

The combination of a well-designed seal profile and the constant force from a spring energizer allows these seals to effectively contain pressurized fluids and gases without leaking, which is their primary function.

Understanding the Trade-offs

No single material is a universal solution. Understanding PTFE's limitations is just as important as knowing its strengths to ensure you are making the correct engineering choice.

The Challenge of Deformation (Creep)

Unfilled PTFE gaskets are often not ideal for very high-pressure applications. The material can deform or "creep" under extreme mechanical stress, potentially leading to leaks over time.

When Metal Gaskets are Superior

In situations involving extreme mechanical stress and pressure, metal gaskets are often the preferred choice. Their superior strength and resistance to deformation provide a more robust and reliable seal under the most demanding conditions.

High-Speed vs. High-Pressure Designs

A seal's design is often optimized for a specific condition. A profile designed for high speed and low pressure will feature lightly loaded, flexible lips. This is fundamentally different from a high-pressure design, which requires a more robust profile to handle the force.

Making the Right Choice for Your Goal

Selecting the correct seal requires matching the material and design to your specific operational demands.

- If your primary focus is extreme temperature range: Standard PTFE offers an excellent thermal profile for both cryogenic and high-heat applications.

- If your primary focus is high-pressure sealing: Prioritize spring-energized designs and consider filled PTFE compounds to ensure seal integrity and prevent deformation.

- If your primary focus is high-speed dynamic sealing: Look for PTFE seal profiles with flexible, lightly loaded lips, but remain mindful of their lower pressure limits.

By understanding how PTFE's material properties are enhanced by intelligent design, you can confidently select a seal that will perform reliably in the most challenging environments.

Summary Table:

| Key Feature | Benefit for High-Temp/High-Pressure |

|---|---|

| Thermal Stability (-260°C to +300°C) | Maintains integrity in extreme heat and cryogenic conditions |

| Spring-Energized Design | Provides constant sealing force against pressure fluctuations |

| Reinforcing Fillers (e.g., Bronze) | Enhances strength and prevents deformation under load |

| Low Friction Coefficient | Reduces wear and heat generation in dynamic applications |

Need a PTFE seal that performs reliably in your demanding application? KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders, ensuring your seals are engineered to withstand extreme temperatures and pressures. Contact us today to discuss your specific requirements and let our expertise enhance your system's performance and longevity.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the uses of Polytetrafluoroethylene (PTFE) with a Proprietary Fill? Enhance Performance for Demanding Applications

- How does a PTFE liner function in a spherical bearing or rod end? Achieve Maintenance-Free, Self-Lubricating Performance

- How can PTFE sheets be customized for specific industrial needs? Tailor Performance for Your Application

- Why is PTFE considered the best material for heavy-duty cable liners? Achieve Superior Reliability & Efficiency

- How do PTFE-lined diaphragm valves contribute to cost savings? Reduce Operational Costs & Downtime

- How do the non-stick properties of PTFE oil seals contribute to their performance? Ensure Long-Term Reliability in Harsh Conditions

- What are the temperature resistance properties of PTFE O-rings? Withstand -200°C to 260°C Extremes

- What are the different types of PTFE seals and their applications? Match the Right Seal to Your Application