For creating round or conical shapes in Polytetrafluoroethylene (PTFE), the ideal machining technique is turning. While PTFE is exceptionally easy to machine on standard equipment, its unique properties—namely its softness, high thermal expansion, and tendency to deform under pressure—demand a specific approach. Success depends less on the machine itself and more on the correct tooling, speeds, and handling techniques.

The core challenge of machining PTFE isn't cutting it, but controlling its shape. Turning is the correct method for round parts, but achieving dimensional accuracy requires managing the material's inherent instability with sharp tools, moderate speeds, and minimal pressure.

Why Turning is the Right Choice for PTFE

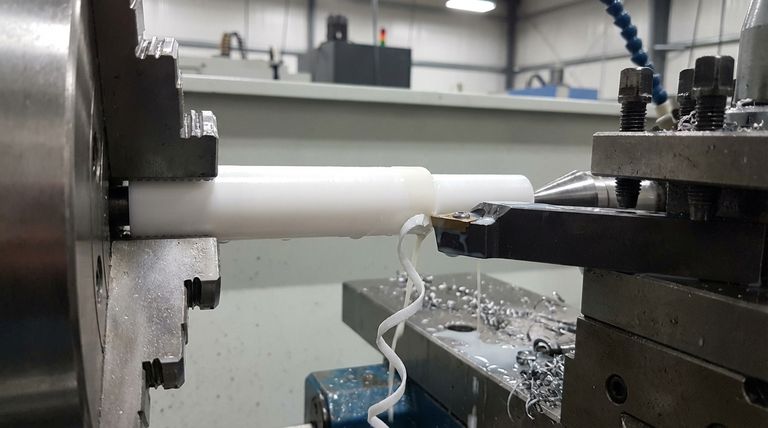

Turning is a machining process where a cutting tool, typically a single-point tool, moves linearly while the workpiece rotates. This method is fundamentally suited for creating parts with rotational symmetry.

The Mechanics of Turning

A lathe secures and rotates the PTFE stock at high speed. A stationary cutting tool is then advanced into the material, precisely removing material to create cylindrical profiles, tapers (cones), grooves, and faces. This continuous cutting action is perfect for producing the smooth, symmetrical surfaces required for round parts.

How PTFE's Properties Align with Turning

PTFE’s softness means it offers very little resistance to a sharp cutting tool. In a turning operation, this allows for a clean, slicing action that peels material away smoothly. Unlike milling, which can involve interrupted cuts, the constant engagement of a turning tool provides a consistent finish ideal for this material.

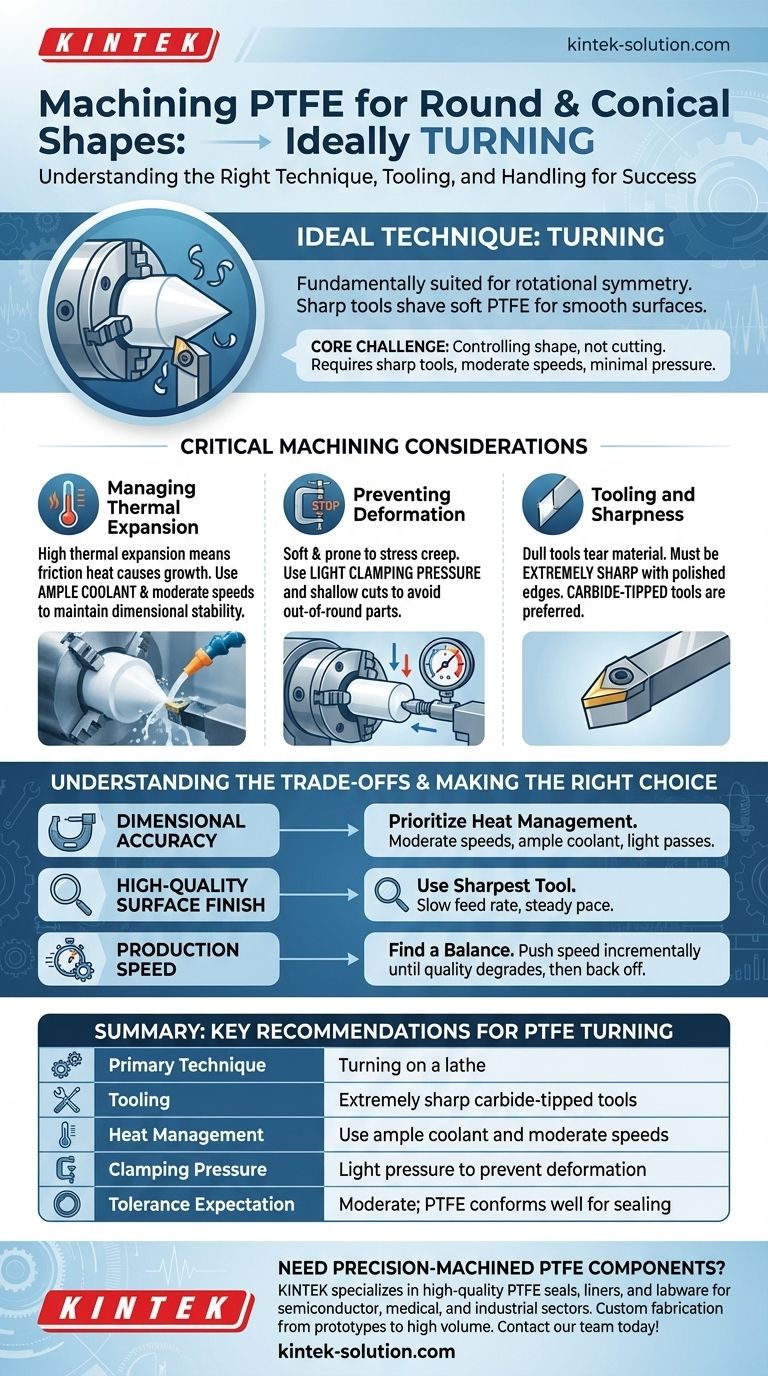

Critical Machining Considerations for PTFE

Simply putting PTFE in a lathe is not enough. You must actively manage its properties to achieve an accurate result. The primary goals are to minimize heat and prevent physical deformation.

Managing Thermal Expansion

PTFE has an exceptionally high coefficient of thermal expansion. The friction from cutting generates heat, causing the material to expand significantly. If not controlled, a part measured as correct while warm will be undersized once it cools.

Using a generous amount of coolant or lubricant is essential to dissipate this heat at the source. Paired with moderate cutting speeds, this is the most effective strategy for maintaining dimensional stability.

Preventing Deformation

The material is soft and prone to stress creep, meaning it will deform over time under constant pressure. Overtightening the chuck jaws on a lathe will compress the material, leading to an out-of-round or undersized part once the pressure is released.

Always use light clamping pressure—just enough to securely hold the workpiece. Similarly, use a shallow depth of cut to avoid pushing the material away from the tool rather than cutting it.

Tooling and Sharpness

Dull tools will not cut PTFE; they will tear and deform it, resulting in a poor surface finish and inaccurate dimensions. Tools must be extremely sharp with a polished cutting edge to ensure a clean slicing action.

High-speed steel (HSS) is acceptable, but carbide-tipped tools are preferred for their superior edge retention and performance.

Understanding the Trade-offs

Machining PTFE involves balancing competing factors. Understanding these compromises is key to avoiding common frustrations.

The Challenge of Tight Tolerances

Achieving tight, precise tolerances with PTFE is difficult and often unnecessary. Its natural resilience allows it to conform and seal in many applications. It is often better to design the part to leverage this property rather than fighting the material's nature by demanding rigid precision that it cannot hold.

Surface Finish vs. Speed

While you can cut PTFE at high speeds, doing so generates more heat and risks a poor surface finish. For the best possible finish, prioritize slower feed rates and very sharp tooling over high rotational speeds. This gives the tool time to create a smooth slicing action.

The Need for Coolant

While short or rough cuts can sometimes be done dry, any work requiring accuracy demands coolant. Machining without it guarantees a buildup of heat, which is the primary source of dimensional error when working with PTFE.

Making the Right Choice for Your Goal

Select your parameters based on the most important outcome for your specific part.

- If your primary focus is dimensional accuracy: Prioritize heat management with moderate speeds, ample coolant, and light passes to prevent thermal expansion.

- If your primary focus is a high-quality surface finish: Use the sharpest, most polished tool possible combined with a slow, steady feed rate.

- If your primary focus is production speed: Find a balance; pushing speed too aggressively will compromise both accuracy and finish, so increase speed incrementally until quality begins to degrade, then back off slightly.

Ultimately, successfully machining PTFE comes from respecting the material's properties rather than trying to force it to behave like metal.

Summary Table:

| Key Consideration | Recommendation for PTFE Turning |

|---|---|

| Primary Technique | Turning on a lathe |

| Tooling | Extremely sharp carbide-tipped tools |

| Heat Management | Use ample coolant and moderate speeds |

| Clamping Pressure | Light pressure to prevent deformation |

| Tolerance Expectation | Moderate; PTFE conforms well for sealing |

Need precision-machined PTFE components? KINTEK specializes in manufacturing high-quality PTFE seals, liners, and labware for the semiconductor, medical, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures your parts are made with the precise techniques and care that PTFE demands. Contact our team today to discuss your project requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application