Using reprocessed Polytetrafluoroethylene (PTFE) in chemical applications introduces significant risks, primarily stemming from potential impurities and structural degradation. The reprocessing cycle can compromise the very molecular structure that gives PTFE its exceptional chemical inertness, leading to unpredictable performance and potential contamination of sensitive processes.

The core issue with reprocessed PTFE is the loss of predictability. While offering cost savings, the recycling process can introduce unknown contaminants and break down its stable fluorine-carbon bonds, undermining the material's reliability in demanding chemical environments.

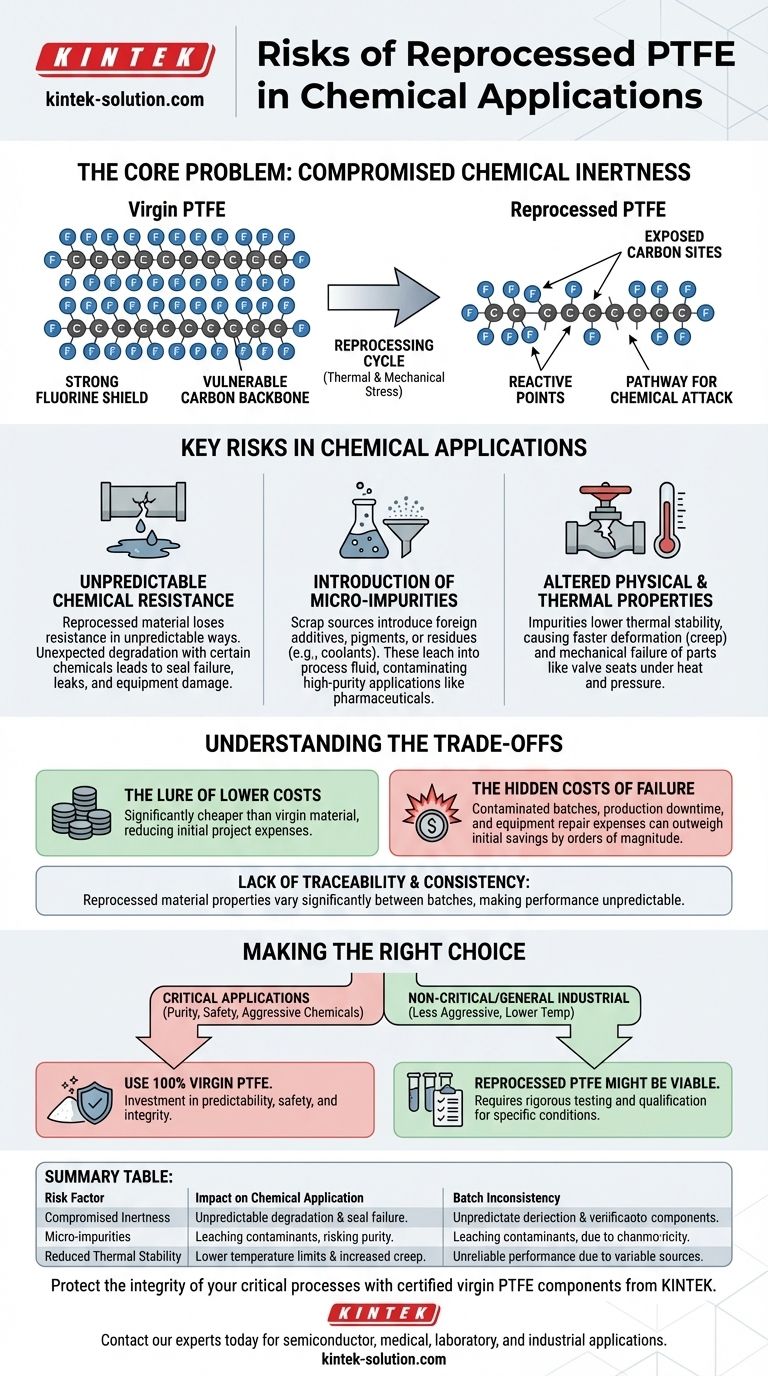

The Core Problem: Compromised Chemical Inertness

To understand the risks, we must first appreciate what makes virgin PTFE so effective. Its properties are rooted in its unique molecular structure.

The Role of Fluorine Shielding

Pure PTFE consists of a long chain of carbon atoms completely surrounded by fluorine atoms. The carbon-fluorine bond is exceptionally strong and stable.

This dense "shield" of fluorine atoms protects the vulnerable carbon backbone from reacting with outside chemicals, which is the source of PTFE's legendary non-reactivity.

How Reprocessing Breaks the Shield

The thermal and mechanical stress of grinding, melting, and reforming PTFE can break some of these stable bonds.

This degradation exposes carbon atoms that are normally shielded. These exposed sites become reactive points, creating a pathway for chemical attack that does not exist in virgin material.

Key Risks in Chemical Applications

When this compromised material is used in a chemical pipeline, valve, or container, several specific issues can arise.

Unpredictable Chemical Resistance

The primary benefit of PTFE is its resistance to nearly all chemicals. Reprocessed material can lose this property in unpredictable ways.

A batch of reprocessed PTFE might resist one chemical but unexpectedly degrade when exposed to another, causing seal failure, leaks, and equipment damage.

Introduction of Micro-Impurities

Reprocessed PTFE is made from scrap material from various sources. This scrap can contain foreign additives, pigments, or residues from its previous life, such as machining coolants.

These micro-impurities can leach into the process fluid, causing contamination that is unacceptable in high-purity applications like pharmaceuticals or semiconductors.

Altered Physical and Thermal Properties

Pure PTFE already has a strict temperature limit, with significant creep and thermal expansion occurring above 200°C (392°F).

Impurities in reprocessed material can lower this thermal stability even further. This can lead to faster deformation of parts like valve seats, causing clogging and mechanical failure under heat and pressure.

Understanding the Trade-offs

The decision to use reprocessed PTFE is almost always driven by cost, but this choice comes with hidden liabilities.

The Lure of Lower Costs

Reprocessed PTFE is significantly cheaper than virgin material, making it an attractive option for reducing initial project expenses.

The Hidden Costs of Failure

However, the cost of a single failure often outweighs any initial savings. The expense of a contaminated chemical batch, production downtime, or equipment repair can be orders of magnitude higher.

Lack of Traceability and Consistency

With virgin PTFE, you receive a consistent, traceable product with certified properties. Reprocessed material lacks this guarantee.

Because the source material is variable, the properties of reprocessed PTFE can differ significantly from one batch to the next, making performance unpredictable.

Making the Right Choice for Your Application

Your decision must be based on a clear assessment of the risks involved in your specific process.

- If your primary focus is ensuring absolute chemical purity and safety (e.g., pharmaceutical, semiconductor, aggressive chemical processing): You must use 100% virgin PTFE, as the risk of contamination and unpredictable failure from reprocessed material is too great.

- If your primary focus is non-critical, general industrial use with less aggressive chemicals and lower temperatures: Reprocessed PTFE might be a viable option, but it requires rigorous testing and qualification for your specific fluid and conditions.

Ultimately, selecting virgin PTFE is an investment in the predictability, safety, and integrity of your critical chemical processes.

Summary Table:

| Risk Factor | Impact on Chemical Application |

|---|---|

| Compromised Inertness | Unpredictable degradation and seal failure with aggressive chemicals. |

| Micro-Impurities | Leaching contaminants into process fluids, risking product purity. |

| Reduced Thermal Stability | Lower temperature limits and increased part deformation (creep). |

| Batch Inconsistency | Unreliable performance due to variable source materials. |

Protect the integrity of your critical processes with certified virgin PTFE components from KINTEK.

For semiconductor, medical, laboratory, and industrial applications where purity and performance are non-negotiable, trust our precision-manufactured PTFE seals, liners, and labware. We use only 100% virgin materials and offer custom fabrication from prototypes to high-volume orders to ensure predictable, reliable performance.

Contact our experts today to discuss your specific requirements and safeguard your operations.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the common applications of Teflon? Discover Its Versatility Across Industries

- What is the temperature range in which PTFE maintains its properties? From -200°C to 260°C

- What is the molecular structure of PTFE? The Key to Its Unmatched Chemical & Thermal Resistance

- What makes ETFE Teflon suitable for aerospace applications? Lightweight & Durable for Harsh Environments

- What are the key properties of PTFE? Discover the Material for Extreme Environments

- What makes PTFE/Teflon suitable for medical applications? Discover Its Unique Biocompatibility & Performance

- What is PTFE and what are its common uses? A Guide to the High-Performance Polymer

- What are the key differences between PTFE and Acetal (POM)? Choose the Right Material for Your Application