The primary issue that arises from PTFE's softness during machining is the difficulty in maintaining dimensional accuracy. This softness can lead directly to problems like tool chatter, material distortion under clamping pressure, and a general inability to hold tight tolerances without specialized techniques.

While PTFE's softness makes it easy to cut, its combination of low strength, high thermal expansion, and susceptibility to compression creates a unique set of machining challenges. Success depends less on brute force and more on finessing the material with the right tools, pressures, and speeds.

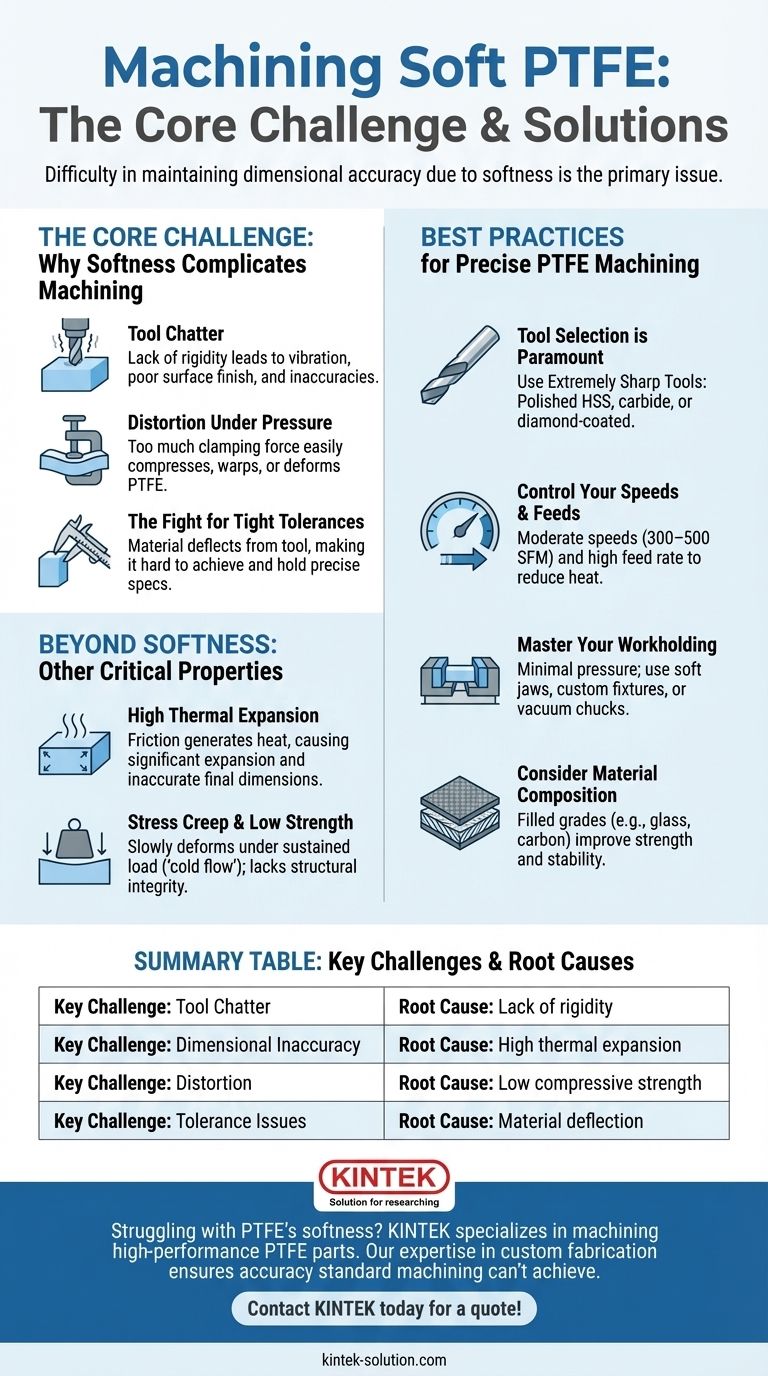

The Core Challenge: Why Softness Complicates Machining

PTFE (polytetrafluoroethylene) is often described as "soapy" or "waxy" to the touch, which hints at its unique machining characteristics. Its inherent lack of rigidity is the root cause of several key issues.

The Problem of Tool Chatter

Tool chatter is a vibration that occurs between the cutting tool and the workpiece. Because PTFE is so soft, it doesn't provide the rigid support needed to dampen these vibrations, often resulting in a poor surface finish and dimensional inaccuracies.

Distortion Under Pressure

One of the most common mistakes is applying too much clamping force. PTFE's softness means it will easily compress, warp, or deform in a standard vise or fixture. This distortion makes it nearly impossible to machine a part to its intended specifications.

The Fight for Tight Tolerances

The material's pliable nature means it can easily deflect away from the cutting tool rather than being cleanly sheared. This makes achieving and holding tight tolerances a significant challenge that requires a specific approach to tooling and cutting parameters.

Beyond Softness: Other Critical PTFE Properties

While softness is the most obvious trait, other linked properties are just as critical to understand for successful machining.

High Thermal Expansion

PTFE has a very high coefficient of thermal expansion. The friction from a cutting tool generates heat, which can cause the material to expand significantly during the machining process, leading to inaccurate final dimensions once it cools.

Stress Creep and Low Strength

Often called "cold flow," stress creep is PTFE's tendency to slowly and permanently deform when under a sustained load, even a light one. This, combined with its low tensile strength, means the material lacks the structural integrity to resist cutting forces without proper support.

Best Practices for Precise PTFE Machining

Successfully machining PTFE involves adapting your process to accommodate its unique properties. The goal is to minimize force, friction, and heat.

Tool Selection is Paramount

The single most important factor is using extremely sharp cutting tools. Polished, high-speed steel (HSS) or carbide tools are recommended. Diamond-coated tools can also provide a superior edge for clean, precise cuts with minimal material adhesion.

Control Your Speeds and Feeds

Use moderate cutting speeds (around 300–500 surface feet per minute) and a high feed rate. This combination helps create a clean chip and removes material quickly, reducing heat buildup and the risk of thermal expansion.

Master Your Workholding

This is a non-negotiable step. Use minimal clamping pressure, keeping forces well below PTFE's yield strength of 20–30 MPa. Employ soft jaws, custom-bored fixtures, or precision vacuum chucks to distribute pressure evenly and support the workpiece fully without causing distortion.

Consider Material Composition

If your application allows, using a filled grade of PTFE (e.g., glass-filled or carbon-filled) can significantly improve its strength and stability. These fillers make the material more rigid and less prone to chatter and thermal expansion.

Understanding the Trade-offs and Safety

Machining PTFE is a balancing act. Understanding its limitations and risks is crucial for planning a successful project.

The Tolerance vs. Cost Balance

Achieving very tight tolerances in virgin PTFE is possible, but it is a slow, careful process that requires specialized fixtures and skilled operators. This inevitably increases machining time and cost compared to more rigid plastics or metals.

The Hazard of Micro Dust

When machined, PTFE can produce fine particle dust. This dust can be hazardous if inhaled. It is essential to work under a coolant to capture these particles or to wear an appropriate protective mask.

Making the Right Choice for Your Application

Your machining strategy should be dictated by your end goal.

- If your primary focus is high precision and tight tolerances: You must invest in extremely sharp tooling, controlled cutting speeds, and custom workholding designed for soft materials.

- If your primary focus is general shaping or prototyping: Standard sharp tools and very careful clamping may suffice, but do not expect to hold tolerances tighter than a few thousandths of an inch.

- If your primary focus is high-volume production: Consider using a filled grade of PTFE to improve machinability and ensure the consistency required for repeatable results.

By respecting PTFE's unique properties, you can transform a challenging material into a predictable and reliable component.

Summary Table:

| Key Challenge | Root Cause | Common Result |

|---|---|---|

| Tool Chatter | Lack of rigidity | Poor surface finish |

| Dimensional Inaccuracy | High thermal expansion | Parts shrink/expand after cooling |

| Distortion | Low compressive strength | Warping under clamping pressure |

| Tolerance Issues | Material deflection | Inability to hold tight specs |

Struggling with PTFE's softness in your precision components? KINTEK specializes in machining high-performance PTFE parts for the semiconductor, medical, and laboratory industries. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures dimensional accuracy and tight tolerances that standard machining can't achieve.

We use specialized tooling, controlled processes, and custom workholding to overcome PTFE's challenges, delivering reliable seals, liners, and labware. Let our precision production solve your PTFE machining problems. Contact KINTEK today for a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How are the dimensions of Teflon encapsulated O-rings defined? Master ID and CS for a Perfect Seal

- What are the limitations of PTFE coated fasteners regarding abrasion resistance? The Trade-Off for Superior Chemical Protection

- Why are PTFE bearing pads essential? Ensure Structural Safety and Longevity with Low-Friction Solutions

- How do expanded PTFE gaskets handle surface irregularities? Achieve a Perfect Seal on Imperfect Flanges

- What are the advantages of Teflon washers? Achieve Superior Performance in Harsh Environments

- How does FR4 PCB material compare to PTFE in terms of electrical properties? Choose the Right Material for Your Application.

- How do PTFE-free bushings compare in longevity to PTFE bushings? Choose for Superior Durability

- What is the cost-benefit analysis of using Teflon gland packing? Maximize ROI with Low-Cost Seals