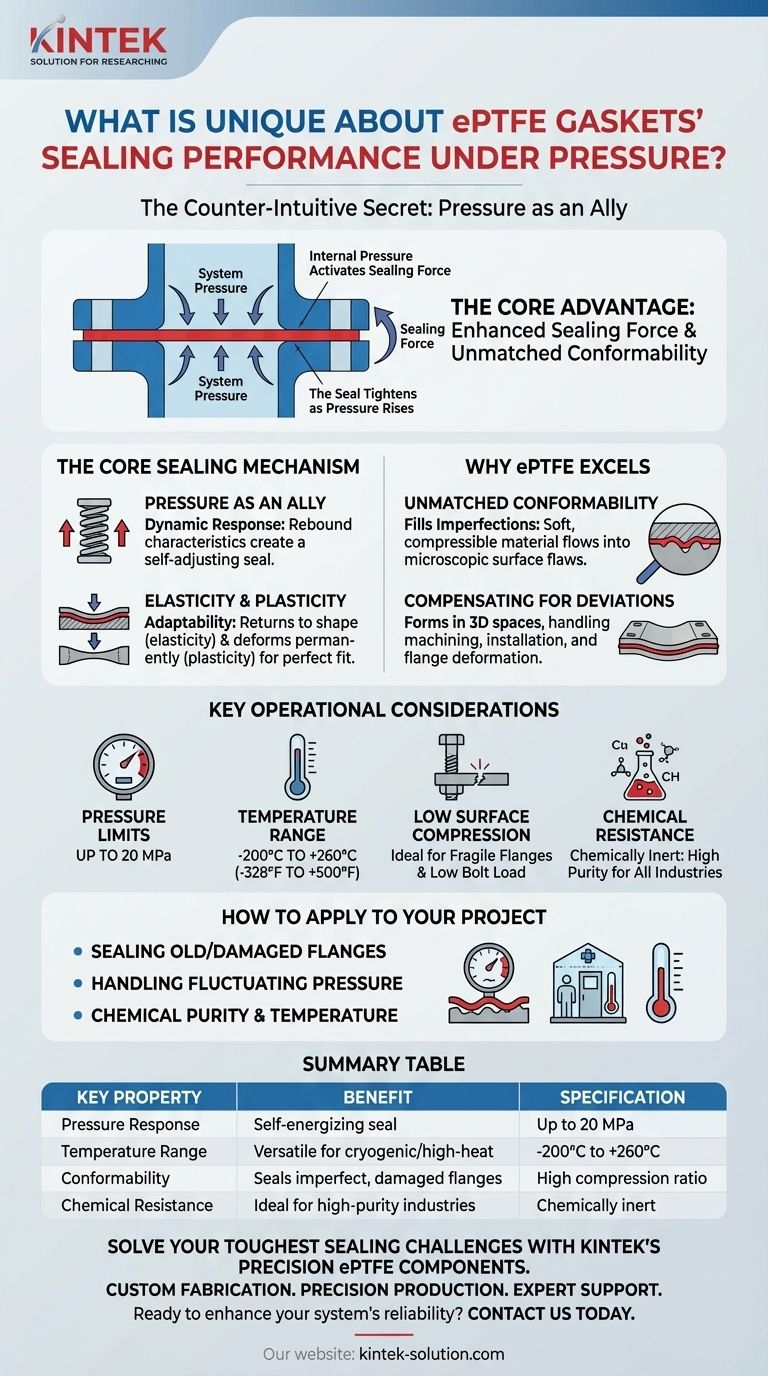

What makes ePTFE gaskets unique is their counter-intuitive response to system pressure. Instead of being a force that threatens to cause a leak, internal pressure actively increases the sealing force of the gasket, creating a more robust and reliable seal precisely when it is needed most.

The core advantage of expanded PTFE (ePTFE) is its ability to use system pressure to enhance its own sealing force, combined with an exceptional ability to conform and seal imperfect surfaces where other materials would fail.

The Core Sealing Mechanism: A Counter-Intuitive Relationship

The true value of ePTFE lies in how its physical properties interact with the forces within a sealed system. It doesn't just block a leak path; it dynamically responds to system changes.

Pressure as an Ally

As the internal pressure within a flange or vessel increases, it pushes against the gasket. Due to ePTFE's rebound characteristics, this external force causes the gasket to press even harder against the sealing surfaces.

This creates a dynamic, self-adjusting seal that becomes tighter as pressure rises.

The Role of Elasticity and Plasticity

ePTFE possesses a unique combination of elasticity (the ability to return to its original shape) and plasticity (the ability to deform permanently).

This allows it to adapt perfectly to the sealing gap while maintaining its sealing integrity under demanding conditions.

Why ePTFE Excels at Sealing Imperfect Surfaces

Many gasket failures occur not because of the gasket material itself, but because the flange surfaces are not perfectly flat or smooth. This is where ePTFE's structure provides a significant advantage.

Unmatched Conformability

The material is soft, flexible, and highly compressible. This allows it to flow into the microscopic imperfections of a sealing surface with minimal compressive force.

It effectively fills small cracks, scratches, voids, and grooves that would create leak paths for more rigid gasket materials.

Compensating for System Deviations

ePTFE's high compression ratio allows it to compensate for deviations caused by machining, installation displacement, or even minor flange deformation under load.

It forms itself easily in three-dimensional spaces, embedding into fine cracks to create a reliable seal in real-world, non-ideal conditions.

Key Operational Considerations

While powerful, understanding the operational envelope of ePTFE is critical for successful implementation. It is not a universal solution, but an expert one for specific challenges.

Pressure and Temperature Limits

These gaskets can reliably withstand internal pressures up to 20 MPa.

They also offer an exceptionally wide operating temperature range, from -200°C to +260°C (-328°F to +500°F), making them suitable for cryogenic and high-heat applications.

The Importance of Low Surface Compression

A key benefit is that ePTFE can maintain seal integrity with relatively low surface compression (bolt load). This makes it ideal for fragile flanges (like glass-lined steel or plastic) that could be damaged by the high torque required for other gasket types.

Exceptional Chemical Resistance

As a member of the PTFE family, ePTFE is chemically inert to most substances. This prevents contamination and makes it a premier choice for industries requiring high purity, such as pharmaceuticals, food and beverage, and semiconductor manufacturing.

How to Apply This to Your Project

Choosing the right gasket depends entirely on the primary challenge you are trying to solve.

- If your primary focus is sealing old, damaged, or irregular flanges: ePTFE is an exceptional choice due to its unmatched ability to conform and fill surface imperfections.

- If your primary focus is handling fluctuating or high system pressure: The self-energizing nature of ePTFE provides a dynamic and reliable seal that improves as pressure increases.

- If your primary focus is chemical purity and temperature resistance: The inert nature and wide operating temperature range of ePTFE make it one of the safest and most versatile options available.

By leveraging ePTFE's unique ability to turn system pressure into a sealing advantage, you can solve your most difficult industrial sealing challenges.

Summary Table:

| Key Property | Benefit | Specification |

|---|---|---|

| Pressure Response | Self-energizing seal tightens under pressure | Up to 20 MPa |

| Temperature Range | Versatile for cryogenic and high-heat uses | -200°C to +260°C |

| Conformability | Seals imperfect, damaged, or irregular flanges | High compression ratio |

| Chemical Resistance | Ideal for high-purity industries | Chemically inert |

Solve your toughest sealing challenges with KINTEK's precision ePTFE components.

Our expanded PTFE gaskets are engineered to deliver the self-energizing sealing performance described in this article. Whether you're dealing with high-pressure systems, irregular flange surfaces, or demanding purity requirements in semiconductor, medical, or laboratory applications, KINTEK provides:

- Custom Fabrication: From prototypes to high-volume orders, we tailor ePTFE seals to your exact specifications.

- Precision Production: Ensure reliable performance with components manufactured to the highest standards.

- Expert Support: Leverage our deep material knowledge to select the optimal solution for your unique application.

Ready to enhance your system's reliability? Contact us today to discuss your project requirements and receive a customized quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- How do the costs of Teflon encapsulated O-rings compare to other sealing solutions? A Guide to Total Cost of Ownership

- What industries benefit from using PTFE rotary seals? Solve Extreme Environment Challenges

- Why are PTFE expansion joints considered an optimal solution for industrial systems?

- What are the advantages of using Expanded PTFE sheet gasket material? Superior Sealing for Demanding Applications

- What support and warranty options are available for custom Teflon parts? Secure Your Investment with Full Manufacturer Backing

- What situations typically require the use of a spring with PTFE seal elements? Overcome PTFE's Limitations for Reliable Sealing

- How does the heat resistance of Teflon plastic sheets benefit high-temperature applications? Ensure Unmatched Stability and Reliability

- How does PTFE contribute to the sealing performance of ball valves? Achieve Leak-Free, Durable Sealing