The significance of temperature stability in PTFE-lined vials is their ability to deliver consistent and reliable performance across a broad operational temperature range. This characteristic is crucial for applications involving extreme heating or cooling, ensuring the integrity of the sample and the accuracy of the results.

PTFE-lined vials offer a unique combination of chemical inertness and thermal resilience. However, understanding their specific temperature limits is not just a recommendation—it is essential for preventing catastrophic failure, such as sample leakage, which can compromise entire experiments.

The Foundation of Reliability: Consistent Performance

Why a Wide Temperature Range Matters

Many analytical and research processes require samples to be subjected to significant temperature changes. PTFE’s stability ensures that the vial itself does not become a variable in the experiment.

It maintains its structural integrity and chemical inertness whether the application involves high-heat digestion or cryogenic storage.

The Impact on Durability

The inherent stability of PTFE contributes directly to its physical durability. The material is highly resistant to wear and degradation over time, even with repeated thermal cycling.

This longevity makes PTFE-lined vials a cost-effective and more sustainable solution compared to less robust alternatives that require frequent replacement.

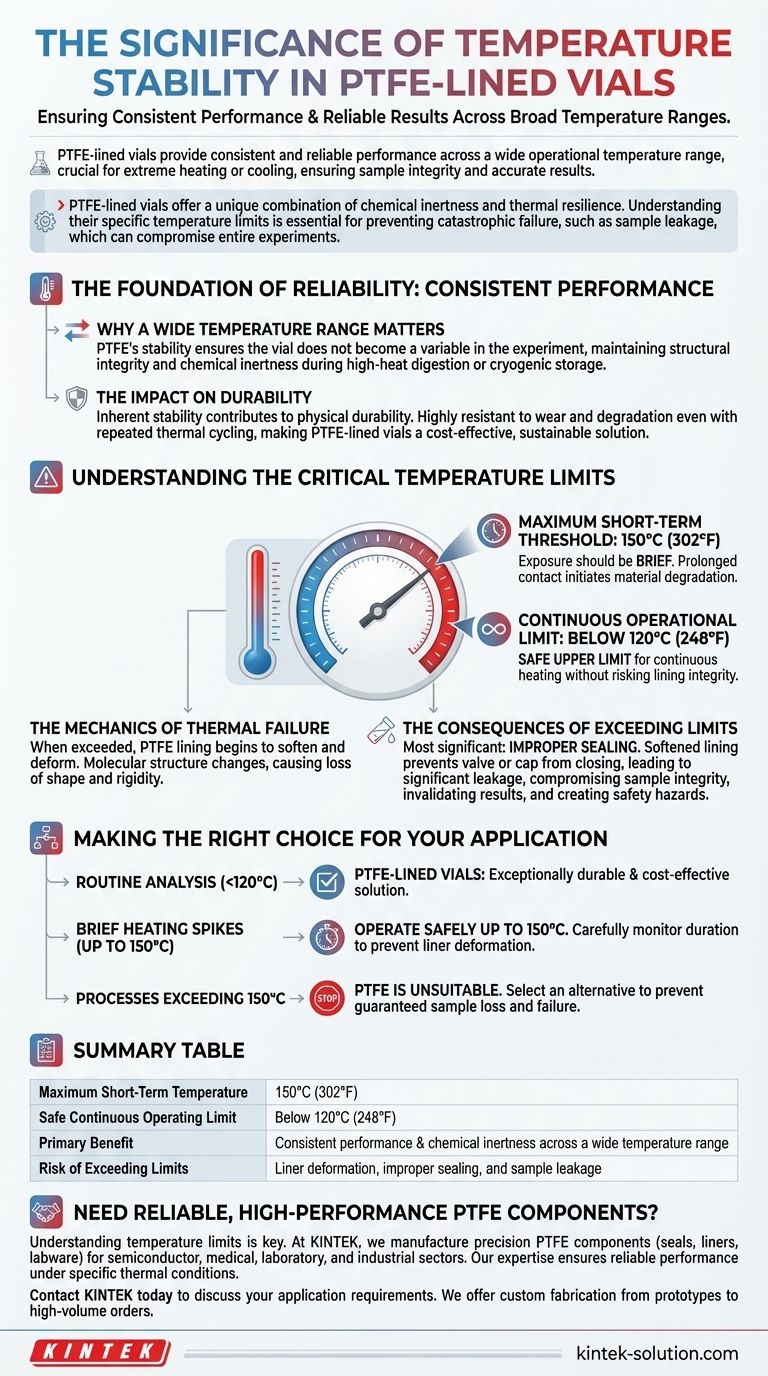

Understanding the Critical Temperature Limits

This is the most critical aspect of using PTFE-lined vials correctly. While they are robust, they are not invincible, and exceeding their thermal limits leads to predictable failure.

The Maximum Short-Term Threshold

The absolute maximum temperature for a PTFE lining is 150°C (302°F). Exposure should be brief, as prolonged contact at this temperature initiates material degradation.

The Continuous Operational Limit

For consistent, long-term use, the operational temperature must remain below 120°C (248°F). This is the safe upper limit for continuous heating without risking the integrity of the lining.

The Mechanics of Thermal Failure

When these temperature limits are exceeded, the PTFE lining begins to soften and deform. Its molecular structure changes, causing it to lose its shape and rigidity.

The Consequences of Exceeding Limits

The most significant consequence of this deformation is improper sealing. A softened lining can prevent a valve or cap from closing correctly, leading to significant leakage of the vial's contents.

This failure compromises sample integrity, invalidates experimental results, and can create potential safety hazards.

Making the Right Choice for Your Application

To ensure reliable performance, match the vial's capabilities to your specific operational needs.

- If your primary focus is routine analysis below 120°C: PTFE-lined vials offer an exceptionally durable and cost-effective solution for your work.

- If your primary focus is applications with brief heating spikes: You can operate safely up to the 150°C limit, but carefully monitor the duration to prevent liner deformation.

- If your primary focus is processes that exceed 150°C: PTFE is an unsuitable material, and you must select an alternative to prevent guaranteed sample loss and experimental failure.

By respecting these defined thermal boundaries, you can fully leverage the reliability and durability that PTFE offers.

Summary Table:

| Key Aspect | Details |

|---|---|

| Maximum Short-Term Temperature | 150°C (302°F) |

| Safe Continuous Operating Limit | Below 120°C (248°F) |

| Primary Benefit | Consistent performance & chemical inertness across a wide temperature range |

| Risk of Exceeding Limits | Liner deformation, improper sealing, and sample leakage |

Need Reliable, High-Performance PTFE Components?

Understanding temperature limits is key to experimental success. At KINTEK, we manufacture precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your components perform reliably under specific thermal conditions, preventing failure and protecting your samples.

We offer custom fabrication from prototypes to high-volume orders, tailoring solutions to your exact needs.

Contact KINTEK today to discuss your application requirements and ensure your PTFE components are built for stability and durability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability