In practice, the reliable continuous operating temperature for a standard PTFE-lined butterfly valve should be kept below 120°C (248°F). While short-term exposure up to 150°C (302°F) may be acceptable, exceeding these limits compromises the valve's mechanical integrity and can lead to catastrophic seal failure.

The crucial distinction is between the chemical stability of the PTFE material itself and the mechanical performance of the assembled valve. High temperatures cause the PTFE lining to soften and deform under pressure, preventing a proper seal long before the material begins to chemically break down.

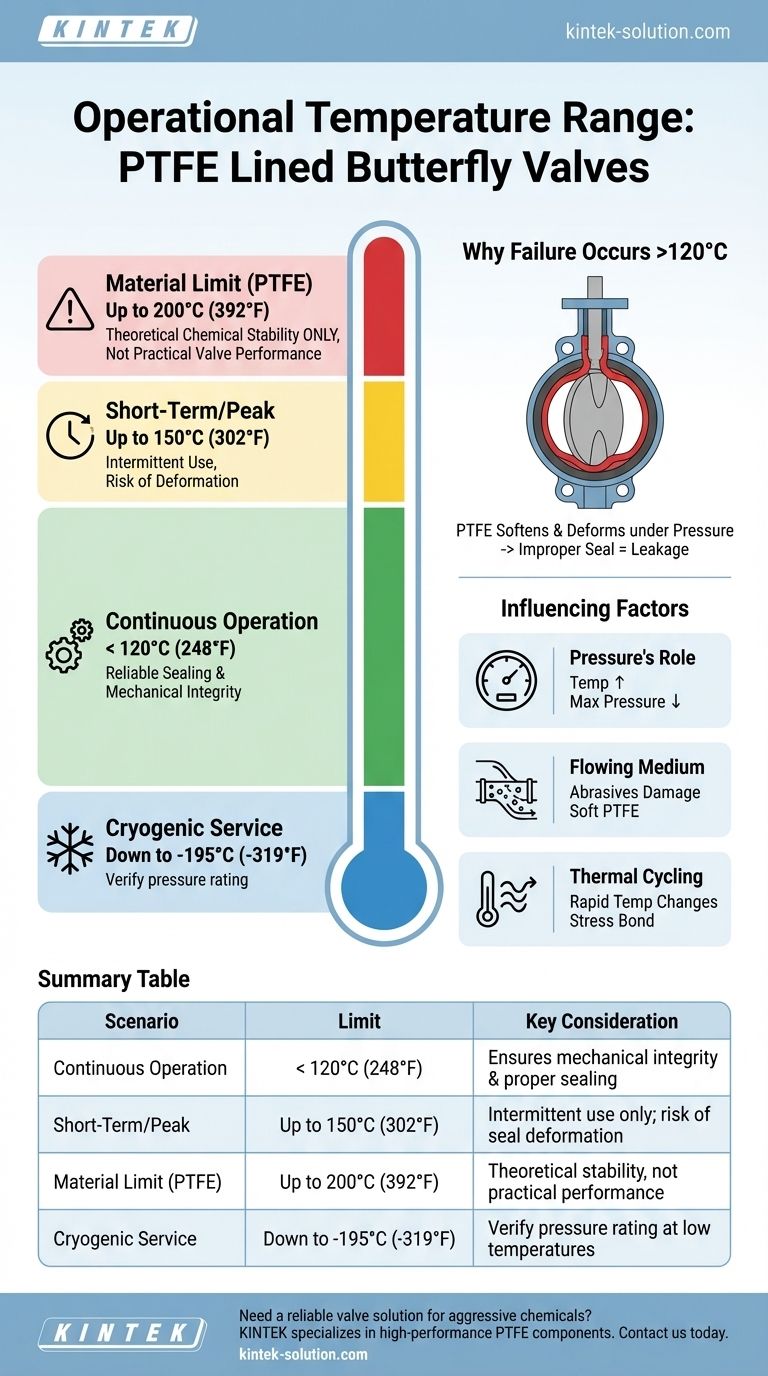

Deconstructing the Temperature Ratings

To select the correct valve, you must understand the difference between the material's theoretical limits and the valve's practical, in-service limits.

The Theoretical Material Limit

Polytetrafluoroethylene (PTFE) as a material boasts an exceptionally wide service temperature range, from cryogenic lows of -195°C (-319°F) up to 200°C (392°F).

Within this range, the material remains chemically inert and stable, which is why it is specified for extreme environments.

The Practical Operating Limit

The functional limit of the valve assembly is much lower. For continuous operation, the process medium should not exceed 120°C (248°F).

A peak temperature of 150°C (302°F) is often cited as the absolute maximum for intermittent, short-term use only.

Why Higher Temperatures Cause Failure

As temperatures rise above 120°C, the PTFE lining begins to lose its rigidity. It softens and can be deformed by the pressure of the disc closing or by the line pressure itself.

This deformation leads to an improper seal between the valve disc and the seat, causing significant leakage and rendering the valve ineffective.

Understanding the Trade-offs and Limitations

Temperature is the primary factor, but it doesn't exist in a vacuum. The valve's performance is a function of its total operating environment.

Pressure's Critical Role

A valve's temperature rating is always linked to its pressure rating. As the temperature of the medium increases, the maximum pressure the valve can safely handle decreases.

Operating at both the maximum rated temperature and maximum rated pressure simultaneously is a common cause of premature failure. Always consult the manufacturer's pressure-temperature curve.

The Impact of the Flowing Medium

The nature of the fluid or gas is critical. PTFE linings are soft and susceptible to physical damage.

The medium must not contain hard particles, crystals, or other abrasive impurities. These will scratch and wear down the lining during operation, compromising the seal and drastically reducing the valve's service life, regardless of temperature.

The Risk of Thermal Cycling

Applications involving frequent and rapid temperature changes (thermal cycling) create additional stress.

The different expansion and contraction rates between the metal valve body and the PTFE liner can fatigue the material and weaken the bond, potentially leading to delamination and seal failure over time.

Making the Right Choice for Your Application

Use these guidelines to determine if a standard PTFE-lined valve fits your operational requirements.

- If your primary focus is corrosion resistance below 120°C: A PTFE-lined valve is an excellent and cost-effective choice for handling aggressive chemicals in this temperature range.

- If your process operates continuously above 120°C or has abrasives: You must consider a valve with a different seat material, such as a high-performance metal-seated butterfly valve.

- If your primary focus is cryogenic service: PTFE's properties make it suitable for extremely low temperatures, but you must verify the valve's pressure rating at your specific cryogenic target.

Ultimately, respecting the valve's proven operational limits is the key to ensuring system safety and reliability.

Summary Table:

| Temperature Scenario | Recommended Limit | Key Consideration |

|---|---|---|

| Continuous Operation | < 120°C (248°F) | Ensures mechanical integrity and proper sealing |

| Short-Term/Peak | Up to 150°C (302°F) | Intermittent use only; risk of seal deformation |

| Material Limit (PTFE) | Up to 200°C (392°F) | Theoretical chemical stability, not practical valve performance |

| Cryogenic Service | Down to -195°C (-319°F) | Verify pressure rating at low temperatures |

Need a reliable valve solution for aggressive chemicals or extreme temperatures?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom seals and liners for the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures your equipment operates safely and efficiently within its specified limits.

We offer custom fabrication from prototypes to high-volume orders to meet your exact application requirements.

Contact our experts today to discuss your specific needs and ensure optimal valve performance and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability