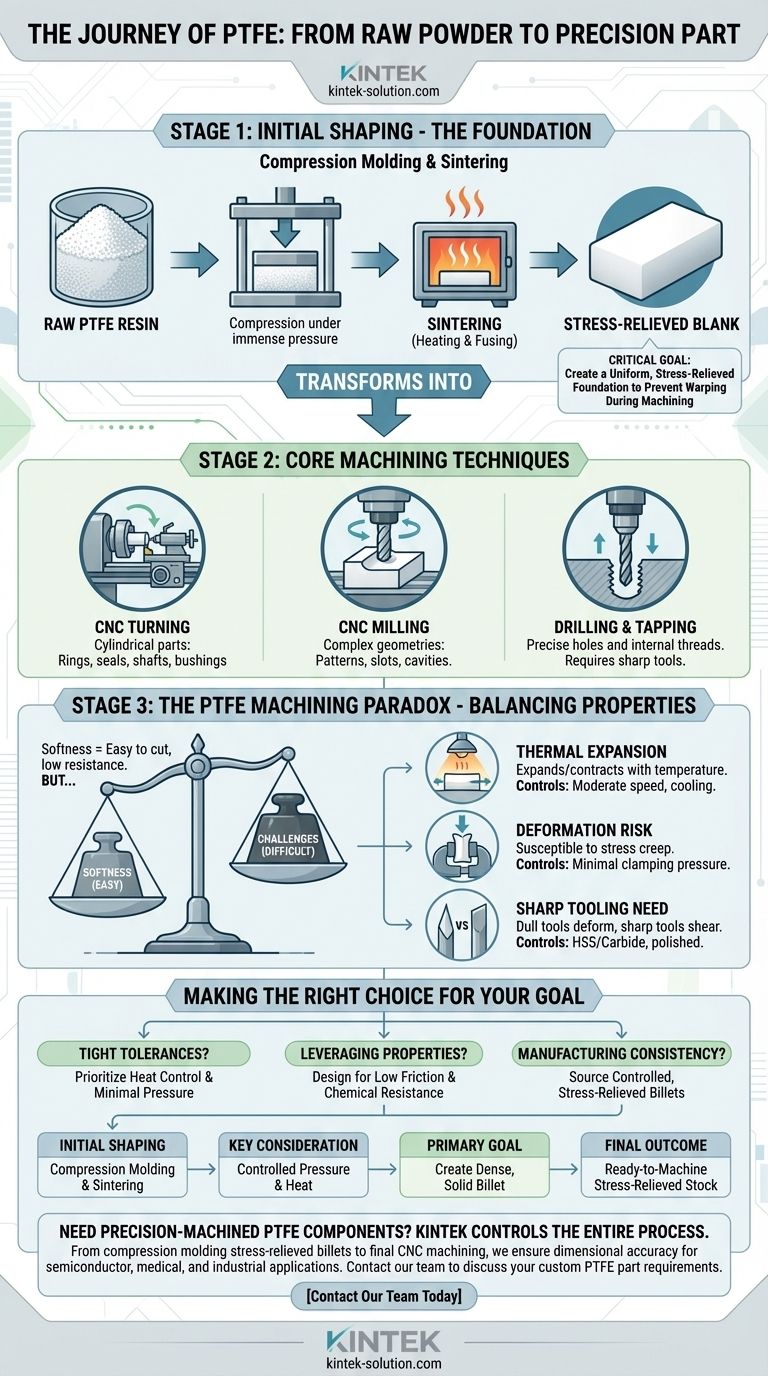

Before PTFE can be machined into a final component, it must first be consolidated from a powder resin into a solid, workable form. This initial shaping process is known as compression molding, where the raw PTFE resin is placed into a mold and subjected to immense pressure and heat, forming it into a dense block, sheet, or billet suitable for subsequent machining operations.

The core challenge with PTFE isn't the cutting itself, but managing the material's unique characteristics. While its softness makes it easy to machine, its high thermal expansion and tendency to deform under pressure demand a specialized approach from initial molding to the final cut to ensure dimensional accuracy.

The Foundation: From Raw Resin to Solid Stock

The journey from a granular powder to a precision part begins with creating a stable, high-quality blank. The initial molding process is not just about shape; it's about creating a predictable material foundation.

Why Compression Molding is the Standard

PTFE resin does not melt and flow like common thermoplastics. Instead, it must be compacted under pressure and then heated in a process called sintering to fuse the particles together into a solid, uniform mass.

This process transforms the loose powder into a dense, solid billet or "preform." This is the essential stock material that a machinist will place into a CNC machine.

The Goal: A Stress-Relieved Machining Blank

A critical outcome of proper compression molding and sintering is a stress-relieved blank. An improperly processed blank can contain internal stresses that cause the material to warp or change shape unpredictably once machining begins, compromising the accuracy of the final part.

Core Machining Techniques for PTFE

Once a quality stock material is secured, it can be shaped using standard equipment, provided the right techniques are employed. PTFE’s properties make it compatible with several common machining methods.

CNC Turning

For creating cylindrical parts like rings, seals, shafts, and bushings, CNC turning is the primary method. A workpiece is rotated while a cutting tool is moved along its axis to shape it.

CNC Milling

When a design requires more complex geometries, such as intricate patterns, slots, or cavities, CNC milling is used. This process involves a rotating cutting tool that removes material from a stationary workpiece.

Drilling and Tapping

Creating precise holes and internal threads is a common requirement. This is accomplished with standard drilling and tapping operations, though tool sharpness is paramount to avoid deforming the material.

Understanding the Trade-offs: The PTFE Machining Paradox

PTFE is paradoxically both easy and difficult to machine. Its softness means tools cut through it with little resistance, but its other properties create significant challenges that must be actively managed.

The Challenge of Thermal Expansion

PTFE has a very high coefficient of thermal expansion. This means it expands and contracts significantly with changes in temperature. The heat generated during cutting can easily cause the part to go out of tolerance if not controlled with moderate cutting speeds and proper cooling.

The Risk of Deformation

Due to its softness and tendency for stress creep, PTFE can be easily compressed or deformed. Applying too much clamping pressure in a vise or chuck will squeeze the material, leading to an inaccurate part once the pressure is released.

The Critical Need for Sharp Tooling

Using extremely sharp and polished cutting tools, preferably high-speed steel (HSS) or carbide, is non-negotiable. A dull tool will not shear the material cleanly; instead, it will push and deform it, generating excess heat and resulting in a poor surface finish.

Making the Right Choice for Your Goal

Successfully machining PTFE requires designing with its properties, not against them. Acknowledging its strengths and weaknesses from the start is the key to a successful outcome.

- If your primary focus is achieving tight tolerances: You must prioritize heat control through moderate cutting speeds and sharp tools, while using minimal, carefully applied clamping pressure to prevent any deformation.

- If your primary focus is leveraging PTFE's properties: Design the application to take advantage of its low friction and chemical resistance, allowing its natural resilience to conform to working dimensions rather than demanding rigid dimensional stability.

- If your primary focus is manufacturing consistency: Ensure your raw billets are sourced from a reputable supplier who uses a controlled compression molding and sintering process to provide stress-relieved material.

Understanding this full lifecycle, from molding to machining, is the key to transforming PTFE's unique properties into reliable, high-performance components.

Summary Table:

| Process Stage | Key Action | Primary Goal |

|---|---|---|

| Initial Shaping | Compression Molding & Sintering | Create a dense, solid billet from PTFE powder |

| Key Consideration | Controlled pressure and heat | Achieve a stress-relieved, uniform blank |

| Final Outcome | Ready-to-machine stock | Provide a predictable foundation for CNC operations |

Need precision-machined PTFE components you can rely on?

At KINTEK, we control the entire process—from compression molding our own stress-relieved billets to final CNC machining—to ensure dimensional accuracy and part performance. Our expertise in manufacturing PTFE seals, liners, and labware for the semiconductor, medical, and industrial sectors means your project benefits from material knowledge and manufacturing consistency.

Contact our team today to discuss your custom PTFE part requirements, from prototypes to high-volume production.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials