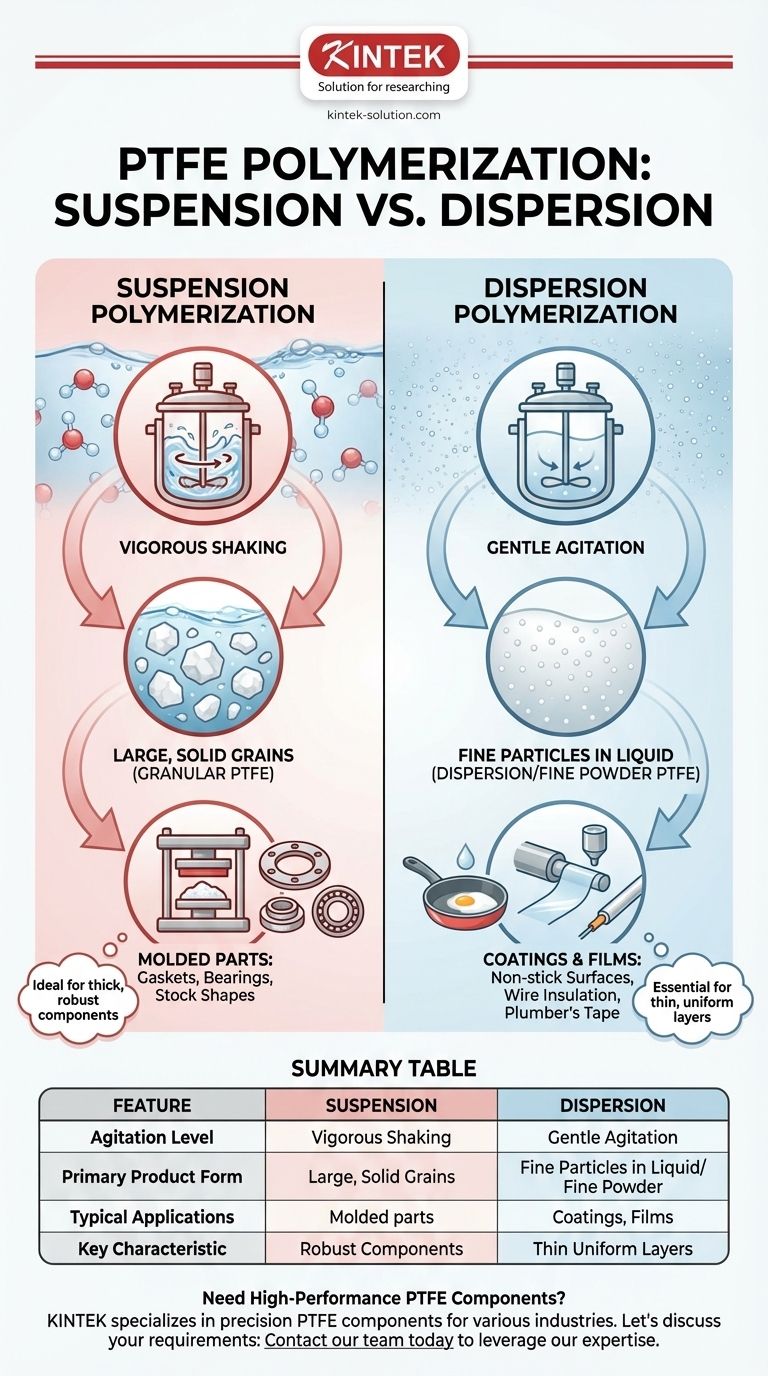

At its core, the difference between suspension and dispersion polymerization of PTFE lies in the level of agitation used during the reaction. Suspension polymerization uses vigorous shaking to produce large, solid grains of PTFE, while dispersion polymerization uses gentle agitation to create a milky liquid dispersion of fine particles. This fundamental process difference dictates the final physical form of the PTFE and, consequently, its industrial applications.

The choice between suspension and dispersion is not arbitrary; it is a deliberate engineering decision. Suspension polymerization is used to create granular PTFE for molding solid parts like gaskets and bearings, whereas dispersion polymerization is used to create fine powders and pastes for thin coatings and films, such as non-stick cookware surfaces.

The Core Process Distinction: Agitation and Particle Formation

The manufacturing method directly controls the physical characteristics of the resulting polymer. The primary variable is the mechanical energy—or agitation—put into the system.

Suspension Polymerization: Creating Granular PTFE

In suspension polymerization, liquid tetrafluoroethylene (TFE) monomer is fed into a reactor of purified water containing an initiator.

The chamber is then vigorously and mechanically shaken. This high-energy environment causes the newly forming polymer chains to agglomerate into larger, solid particles.

These particles, often described as grains, are not soluble in the water and float to the surface. After the reaction, the water is drained, and the resulting stringy, granular PTFE is dried and milled. This product is often called granular PTFE.

Dispersion Polymerization: Forming Fine Particles

The dispersion method also uses TFE, water, and an initiator, but the process conditions are markedly different.

Instead of violent shaking, the reactor is only gently agitated. This low-energy environment prevents the polymer particles from clumping together into large grains.

The result is a stable, milky-white liquid where microscopic PTFE particles (tiny beads) are evenly dispersed in the water. This can be used as a liquid paste or carefully dried to produce a fine powder PTFE, which has a much smaller particle size than granular PTFE.

How Process Dictates Final Product and Application

The physical form of the raw PTFE—granular vs. fine powder—makes each type suitable for entirely different manufacturing techniques and end products.

Suspension PTFE: The Choice for Molded Parts

The larger particle size of granular PTFE makes it ideal for processing methods that require good flow and packing density.

It is the raw material for compression molding, ram extrusion, and isostatic molding. These processes are used to create solid, self-supporting stock shapes and finished parts.

Common applications include industrial seals, gaskets, valve seats, bearings, and stock shapes like rods, tubes, and sheets that are later machined into final components.

Dispersion PTFE: The Basis for Coatings and Films

The extremely fine particles of dispersion PTFE are essential for creating thin, uniform layers.

The liquid dispersion can be applied directly as a coating, which is then heated (sintered) to form a solid, non-stick surface, most famously used on cookware.

When dried into a fine powder, it can be mixed with a lubricant and extruded into very thin films. This is the process used to make thread seal tape (plumber's tape) and high-performance wire insulation.

Understanding the Trade-offs

Neither method is inherently superior; they are optimized for different outcomes. Understanding their limitations is key to material selection.

Granular PTFE (Suspension)

The primary advantage of granular PTFE is its suitability for creating thick, robust, and mechanically strong molded parts. It handles well in molding presses and extruders designed for bulk materials.

Its limitation is its unsuitability for thin film or coating applications. The large grain size prevents the formation of a smooth, thin, and continuous layer.

Fine Powder/Dispersion PTFE

The key strength of dispersion-grade PTFE is its ability to form exceptionally thin, non-porous films and coatings. The fine particle size is critical for these applications.

However, processing it into thick, solid blocks can be more complex than with granular PTFE. While possible, it often requires different techniques, and the resulting mechanical properties might differ from parts molded from granular resin.

Making the Right Choice for Your Goal

The polymerization method is chosen based on the intended final application. Your decision should be guided by the physical form your project requires.

- If your primary focus is manufacturing solid, molded components: You need granular PTFE produced via suspension polymerization.

- If your primary focus is creating thin coatings, films, or wire insulation: You need fine powder or liquid dispersion PTFE made via dispersion polymerization.

Ultimately, the manufacturing process is intentionally designed to control particle size, which is the single most important factor determining how PTFE can be used.

Summary Table:

| Feature | Suspension Polymerization | Dispersion Polymerization |

|---|---|---|

| Agitation Level | Vigorous shaking | Gentle agitation |

| Primary Product Form | Large, solid grains (Granular PTFE) | Fine particles in liquid (Dispersion/Fine Powder PTFE) |

| Typical Applications | Molded parts (gaskets, seals, bearings) | Coatings, films (non-stick surfaces, wire insulation) |

| Key Characteristic | Ideal for thick, robust components | Essential for thin, uniform layers |

Need High-Performance PTFE Components for Your Industry?

Understanding the right PTFE material is the first step. KINTEK specializes in manufacturing precision PTFE components—from seals and liners to custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether your project requires the robust properties of granular PTFE for molded parts or the fine details enabled by dispersion PTFE for coatings, our expertise in custom fabrication from prototypes to high-volume orders ensures you get the perfect solution.

Let's discuss your specific requirements. Contact our team today to leverage our precision production capabilities for your application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the advantages of using Teflon over other polymers? Unmatched Performance in Extreme Conditions

- How is PTFE used in lubrication applications? Achieve Superior Friction Reduction

- What industries commonly use Teflon material? Unlocking Versatility Across Sectors

- Is PTFE a thermoplastic or thermoset material? Unpacking Its Unique Polymer Properties

- Why is stainless steel-filled PTFE ideal for the food processing and pharmaceutical industries? Enhanced Durability Meets Regulatory Compliance

- Why is Teflon considered an exceptional material choice? Unmatched Chemical & Thermal Resistance

- What is modified PTFE and how does it differ from standard PTFE? A Guide to Enhanced Performance

- What medical applications benefit from PTFE? A Guide to Its Critical Role in Healthcare