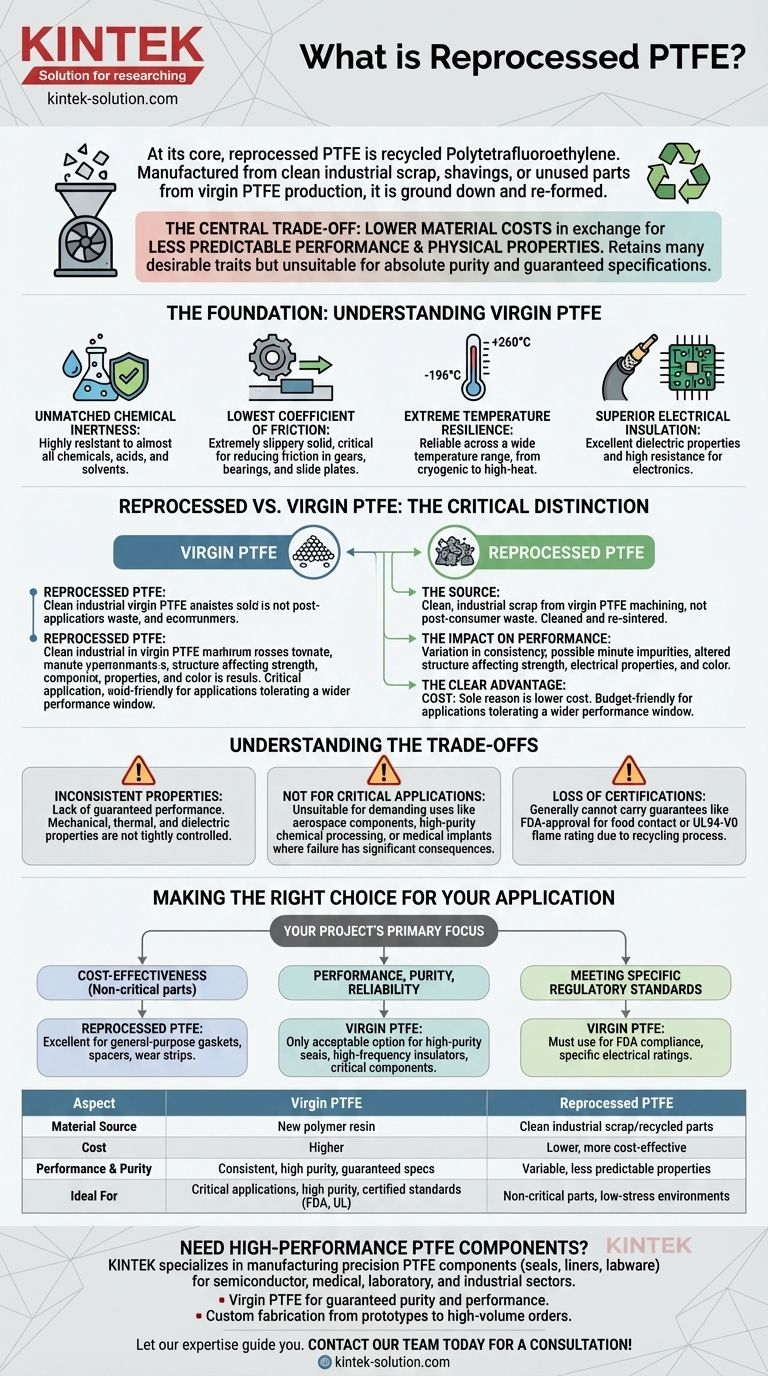

At its core, reprocessed PTFE is recycled Polytetrafluoroethylene. It is manufactured from scrap, shavings, or unused parts generated during the production of virgin PTFE components. This recycled material is ground down and then re-formed into new shapes, offering a more cost-effective alternative to its virgin counterpart.

The central trade-off is simple: reprocessed PTFE lowers material costs in exchange for less predictable performance and physical properties. While it retains many of PTFE's desirable traits, it is not suitable for applications where absolute purity and guaranteed specifications are critical.

The Foundation: Understanding Virgin PTFE

To grasp the implications of using reprocessed material, we must first understand the benchmark properties of virgin PTFE. This synthetic fluoropolymer is renowned for a unique combination of characteristics that make it invaluable across numerous industries.

Unmatched Chemical Inertness

PTFE is virtually immune to chemical attack. It is highly resistant to almost all industrial chemicals, acids, alkalis, and organic solvents, making it a primary choice for handling reactive and corrosive materials.

The Lowest Coefficient of Friction

Often cited as the most slippery solid material known, PTFE has an extremely low coefficient of friction. This non-stick quality is famous in cookware but is also critical for industrial applications like gears, bearings, and slide plates where reducing friction is paramount.

Extreme Temperature Resilience

PTFE performs reliably across an exceptionally wide temperature range, typically from -196°C to +260°C (-321°F to +500°F). It does not become brittle in cryogenic conditions nor degrade in high-heat environments.

Superior Electrical Insulation

With outstanding dielectric properties and high electrical resistance, PTFE is an excellent insulator. This makes it essential for high-frequency electronics, such as in coaxial cables and other critical computer wiring applications.

Reprocessed vs. Virgin PTFE: The Critical Distinction

While both materials originate from the same polymer, the recycling process fundamentally changes the final product.

The Source of Reprocessed PTFE

Reprocessed material is not post-consumer waste. It is typically clean, industrial scrap from the machining of new, virgin PTFE stock. This scrap is collected, cleaned, and re-sintered into usable forms.

The Impact on Performance

The primary consequence of reprocessing is a variation in material consistency. The recycling process can introduce minute impurities or slightly alter the polymer's structure, which may affect its mechanical strength, electrical properties, and even its color.

The Clear Advantage: Cost

The sole reason for choosing reprocessed PTFE is its lower cost. By reusing industrial scrap, manufacturers can offer a budget-friendly material for applications that can tolerate a wider performance window.

Understanding the Trade-offs

Choosing reprocessed PTFE involves accepting a clear set of compromises. Objectively weighing these trade-offs against your project's requirements is essential.

Inconsistent Properties

The most significant drawback is a lack of guaranteed performance. While a batch of reprocessed PTFE may perform well, its mechanical, thermal, and dielectric properties are not as tightly controlled or predictable as those of virgin PTFE.

Not for Critical Applications

Due to this variability, reprocessed PTFE is unsuitable for demanding applications. It should not be used where failure could have significant consequences, such as in aerospace components, high-purity chemical processing, or medical implants.

Loss of Certifications

Virgin PTFE can be certified to meet specific standards, such as being FDA-approved for food contact or having a UL94-V0 flame rating. Reprocessed material generally cannot carry these same guarantees due to the nature of the recycling process.

Making the Right Choice for Your Application

Your final decision should be driven entirely by the demands of the specific application.

- If your primary focus is cost-effectiveness for non-critical parts: Reprocessed PTFE is an excellent choice for components like general-purpose gaskets, spacers, or wear strips in low-stress environments.

- If your primary focus is performance, purity, and reliability: Virgin PTFE is the only acceptable option for high-purity seals, high-frequency insulators, or any component where consistent material properties are non-negotiable.

- If your primary focus is meeting specific regulatory standards: You must use certified virgin PTFE to guarantee compliance with requirements like those from the FDA or for specific electrical ratings.

Ultimately, choosing the correct grade of PTFE is about aligning the material's capabilities with the precise needs of the job.

Summary Table:

| Aspect | Virgin PTFE | Reprocessed PTFE |

|---|---|---|

| Material Source | New polymer resin | Clean industrial scrap/recycled parts |

| Cost | Higher | Lower, more cost-effective |

| Performance & Purity | Consistent, high purity, guaranteed specs | Variable, less predictable properties |

| Ideal For | Critical applications, high purity, certified standards (FDA, UL) | Non-critical parts, low-stress environments |

Need High-Performance PTFE Components?

Choosing between virgin and reprocessed PTFE is critical for your project's success. KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We offer:

- Virgin PTFE for applications demanding guaranteed purity and performance.

- Custom fabrication from prototypes to high-volume orders.

Let our expertise guide you to the right material solution. Contact our team today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining