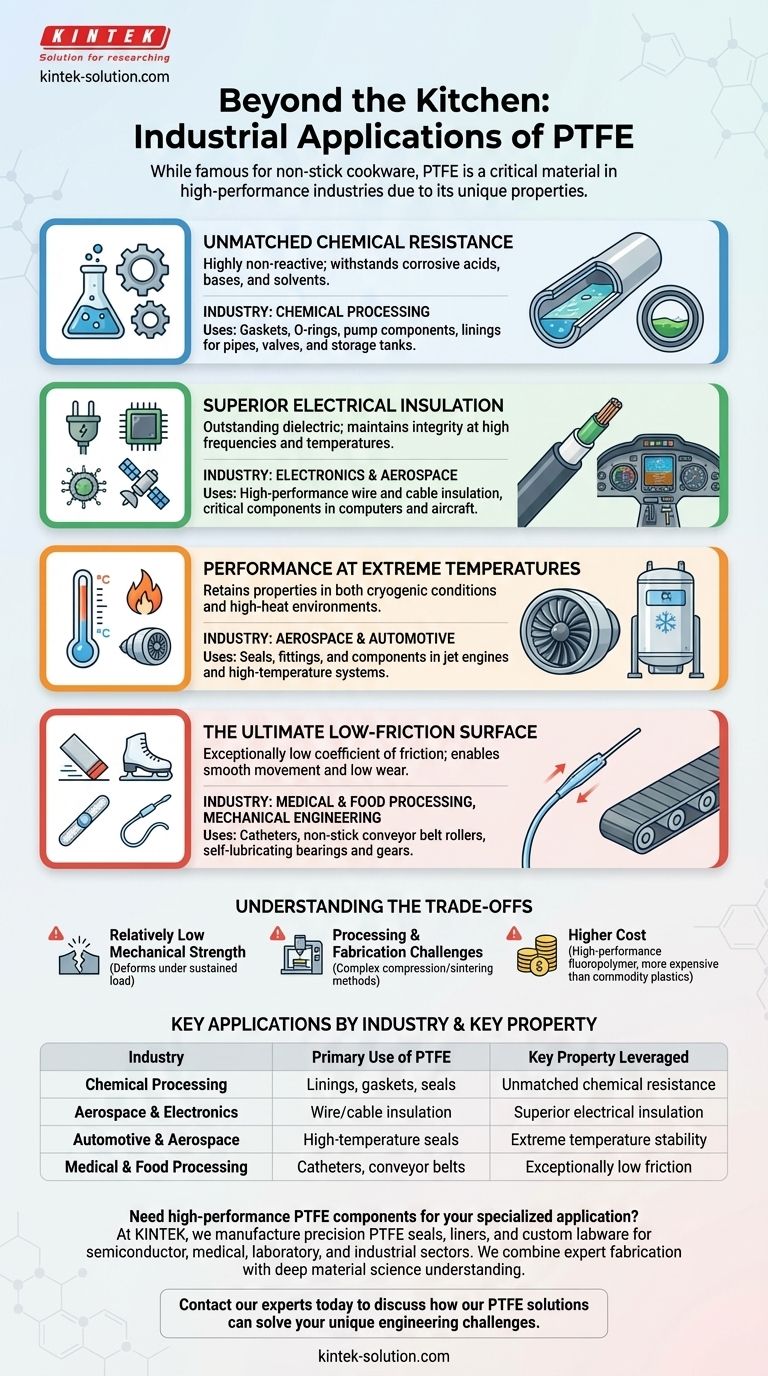

Beyond the kitchen, Polytetrafluoroethylene (PTFE) is a critical material in a vast range of high-performance industries. While famous for its use in non-stick cookware, its most significant applications are in fields like chemical processing, aerospace, electronics, and medicine, where its unique properties solve extreme engineering challenges.

PTFE's widespread industrial adoption is not due to a single feature, but its rare combination of four key properties: near-total chemical inertness, high-temperature stability, excellent electrical insulation, and an exceptionally low coefficient of friction.

Why PTFE Is a Go-To Industrial Material

The non-stick surface of a frying pan is just one application of one of PTFE's properties. In industrial settings, its other characteristics are often far more critical. Understanding these core strengths explains its presence in everything from spacecraft to medical implants.

Unmatched Chemical Resistance

PTFE is one of the most non-reactive substances known. It can withstand highly corrosive acids, bases, and solvents that would destroy most other materials.

This makes it indispensable in the chemical processing industry. It is used for gaskets, O-rings, pump components, and linings for pipes, valves, and chemical storage tanks where contact with aggressive substances is constant.

Superior Electrical Insulation

PTFE is an outstanding electrical insulator, or dielectric. It resists the flow of electricity and maintains its integrity at high frequencies and temperatures.

This property is vital for the electronics and aerospace industries. In fact, a significant portion of all PTFE produced is used for high-performance wire and cable insulation, especially in computers and aircraft where signal integrity and fire safety are paramount.

Performance at Extreme Temperatures

PTFE has a very high melting point and retains its properties over a wide temperature range, performing reliably in both cryogenic conditions and high-heat environments.

This thermal stability is crucial for aerospace and automotive applications. It is used for seals, fittings, and components in jet engines and other systems where extreme temperatures are the norm.

The Ultimate Low-Friction Surface

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "slipperiness" is the same property that prevents food from sticking to a pan.

Industrially, this is leveraged in medical devices like catheters for smooth insertion, food processing for non-stick conveyor belt rollers, and in mechanical engineering for self-lubricating bearings and gears that operate with high efficiency and low wear.

Understanding the Trade-offs

No material is perfect, and PTFE's unique characteristics come with important limitations that engineers must consider.

Relatively Low Mechanical Strength

PTFE is a soft material. It is not used for primary structural components because it can deform or "creep" under sustained load. Its strength lies in its use as a coating, liner, or seal.

Processing and Fabrication Challenges

Due to its high melting point and high melt viscosity, PTFE cannot be processed using conventional melt-processing techniques like injection molding. It is typically shaped using specialized compression and sintering methods similar to those used in powder metallurgy, which can be more complex and costly.

Higher Cost

As a high-performance fluoropolymer, PTFE is significantly more expensive than commodity plastics like polyethylene or polypropylene. Its use is reserved for applications where its unique properties are a strict requirement, not a convenience.

Key Applications by Industry

Your choice of material is always dictated by the problem you need to solve. PTFE is the solution when performance under extreme conditions is non-negotiable.

- If your primary focus is corrosion and chemical handling: PTFE is the industry standard for creating inert linings, seals, and fluid-handling components.

- If your primary focus is high-performance electronics: Its dielectric strength makes it essential for insulating critical wiring in aerospace and computing.

- If your primary focus is reducing friction and wear: It is a premier choice for self-lubricating bearings, low-friction medical devices, and non-stick industrial surfaces.

- If your primary focus is high-temperature stability: Its ability to withstand heat makes it vital for seals and components in demanding automotive and aerospace systems.

Ultimately, PTFE's value lies in its ability to function where lesser materials would fail, making it a cornerstone of modern, high-technology engineering.

Summary Table:

| Industry | Primary Use of PTFE | Key Property Leveraged |

|---|---|---|

| Chemical Processing | Linings, gaskets, seals | Unmatched chemical resistance |

| Aerospace & Electronics | Wire/cable insulation | Superior electrical insulation |

| Automotive & Aerospace | High-temperature seals | Extreme temperature stability |

| Medical & Food Processing | Catheters, conveyor belts | Exceptionally low friction |

Need high-performance PTFE components for your specialized application?

At KINTEK, we manufacture precision PTFE seals, liners, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. We combine expert fabrication with a deep understanding of material science to deliver components that meet your most demanding requirements, from prototypes to high-volume production.

Contact our experts today to discuss how our PTFE solutions can solve your unique engineering challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

People Also Ask

- What are the two main polymerization methods for producing PTFE? Choose the Right Form for Your Application

- What are the similarities between PTFE and RPTFE? Unlocking the Core Fluoropolymer Identity

- What are PTFE micro powders and how are they manufactured? Enhance Your Materials with Fluoroadditives

- What are the modified versions of PTFE and their properties? Enhance Performance for Demanding Applications

- What are the temperature range and mechanical properties of PTFE? The Ultimate Guide to Performance

- When did the industrial production of PTFE begin? From Military Secret to Industrial Revolution

- What are the key chemical resistance properties of PTFE? Discover Its Near-Universal Inertness

- Which industries benefit from Teflon's chemical resistance? Ensure Purity and Safety in Harsh Environments