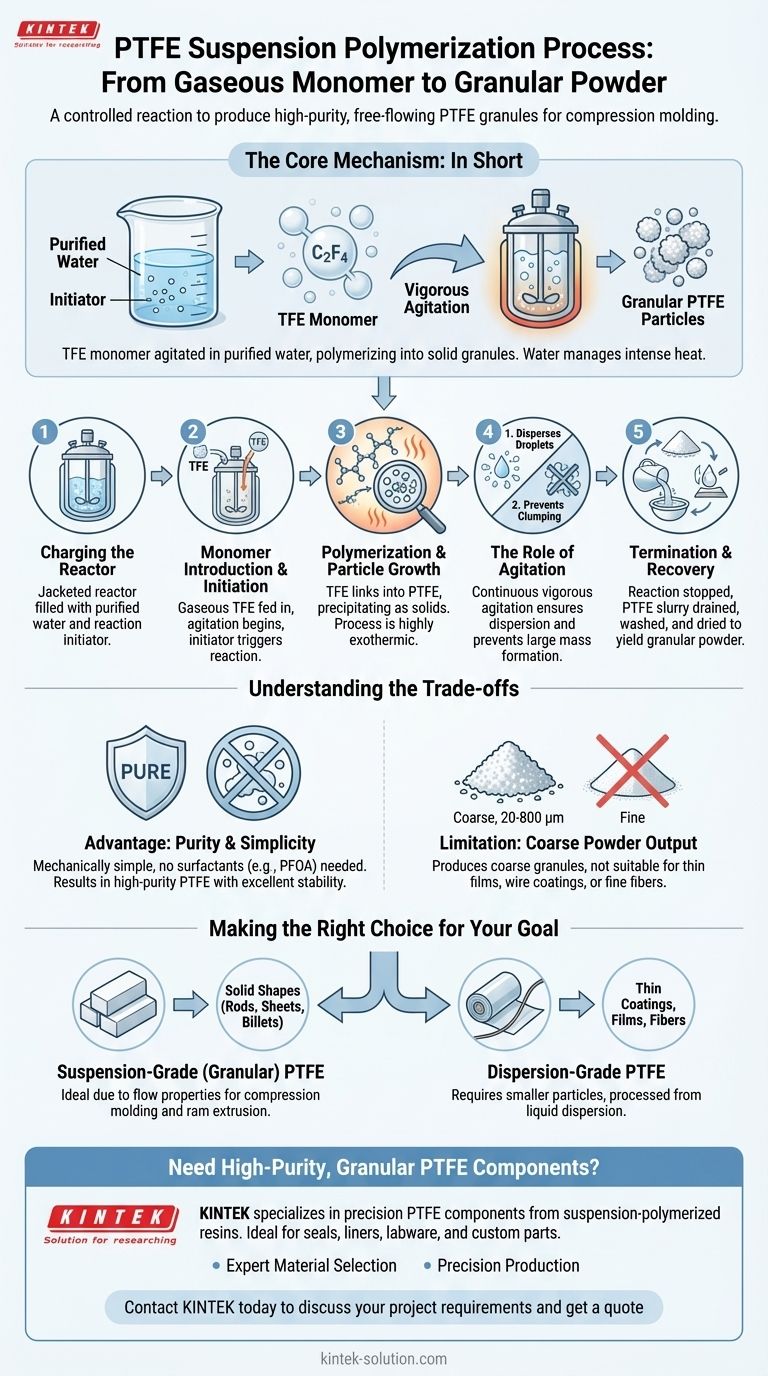

In short, the suspension polymerization of PTFE is a process where gaseous tetrafluoroethylene (TFE) monomer is vigorously agitated in purified water, causing it to polymerize into solid, granular particles. An initiator starts the reaction, and the water acts as a critical medium to suspend the reactants and dissipate the intense heat generated. The process is stopped once the desired amount of polymer is formed, and the resulting granules are separated from the water.

The central purpose of suspension polymerization is not just to create PTFE, but to produce a specific type of it: a granular, free-flowing powder. This method is deliberately chosen to yield large, irregular particles ideal for manufacturing solid stock shapes like rods and sheets through compression molding.

The Core Mechanism: A Step-by-Step Breakdown

To truly understand the material that results from this process, we must look at each stage and its purpose. The entire operation is engineered to control particle size and manage a highly energetic reaction.

Step 1: Charging the Reactor

The process begins by filling a jacketed reactor with highly purified water. This water serves as the suspension medium and, crucially, as a heat transfer agent. A small amount of a reaction initiator (a free-radical source) is dissolved in the water.

Step 2: Monomer Introduction and Initiation

Pressurized, gaseous tetrafluoroethylene (TFE) monomer is then fed into the reactor. The reactor is sealed and brought to the desired temperature and pressure. Vigorous mechanical agitation (shaking or stirring) begins, breaking the TFE gas into small, dispersed droplets within the water. The initiator then triggers the polymerization reaction within these droplets.

Step 3: Polymerization and Particle Growth

As TFE molecules begin linking into long polymer chains (PTFE), they become insoluble and precipitate as solid particles. The reaction is highly exothermic, meaning it releases a significant amount of heat. The surrounding water and the reactor's cooling jacket work continuously to absorb this heat, preventing a runaway reaction.

Step 4: The Role of Agitation

Constant, vigorous agitation is critical. It serves two functions:

- It ensures the TFE droplets remain dispersed, providing a consistent surface area for the reaction.

- It prevents the newly formed, sticky PTFE particles from clumping together into one large, unmanageable mass.

Step 5: Termination and Recovery

The reaction is stopped when a target polymer weight or reaction time is reached. This can be done by cutting off the TFE monomer supply. The agitation is ceased, and the resulting slurry of PTFE granules in water is drained from the reactor. The wet, "stringy" polymer is then washed to remove any residual initiator and dried, yielding a coarse, granular PTFE powder.

Understanding the Trade-offs

Choosing suspension polymerization over other methods, like dispersion, involves a clear set of advantages and limitations that define the final product's use case.

Advantage: Purity and Simplicity

This process is mechanically and chemically simple. Critically, it does not require surfactants (soaps) to maintain the suspension. This avoids the use of chemicals like PFOA, resulting in a higher-purity PTFE with excellent thermal and chemical stability.

Limitation: Inability to Form Films or Coatings

The primary output is a coarse, granular powder with particle sizes typically ranging from 20 to 800 micrometers. These large particles are not suitable for making thin films, wire coatings, or impregnated fabrics, which require the much finer particles produced via dispersion polymerization.

Challenge: Extreme Heat Management

The polymerization of TFE is one of the most energetic polymer reactions known. Insufficient cooling or a failure in the agitation system can lead to a rapid increase in temperature and pressure, creating a significant safety hazard. Therefore, process control is paramount.

Making the Right Choice for Your Goal

The polymerization method directly dictates the physical form of the PTFE resin and, consequently, its applications. Your end goal determines which type you need.

- If your primary focus is producing large, solid shapes (billets, rods, sheets): Suspension-grade (granular) PTFE is the correct choice due to its flow properties and suitability for compression molding and ram extrusion.

- If your primary focus is creating thin coatings, films, or fine fibers: You must use dispersion-grade PTFE, which consists of much smaller particles and is processed from a liquid dispersion to create thin, continuous layers.

Ultimately, understanding the polymerization method is the key to selecting the correct PTFE grade for your specific engineering application.

Summary Table:

| Stage | Key Action | Purpose/Outcome |

|---|---|---|

| 1. Charging | Fill reactor with purified water and initiator. | Creates suspension medium and heat transfer agent. |

| 2. Initiation | Introduce TFE gas and begin vigorous agitation. | Disperses monomer droplets and starts polymerization. |

| 3. Polymerization | Polymer chains form and precipitate as solids. | Generates granular PTFE particles; requires intense cooling. |

| 4. Termination | Stop reaction and recover the polymer slurry. | Yields a coarse, free-flowing granular PTFE powder. |

| Key Advantage | No surfactants required. | Results in high-purity PTFE with excellent stability. |

| Key Limitation | Produces coarse powder. | Not suitable for films or coatings; ideal for molding solid shapes. |

Need High-Purity, Granular PTFE Components?

KINTEK specializes in manufacturing precision PTFE components from suspension-polymerized resins. This process yields the high-purity, granular PTFE ideal for creating durable seals, liners, labware, and custom-molded parts.

We provide:

- Expert Material Selection: We help you choose the right PTFE grade for demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

- Precision Production: From custom prototypes to high-volume orders, we manufacture components that meet your exact specifications.

Let us put our expertise in high-performance polymers to work for you.

Contact KINTEK today to discuss your project requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability