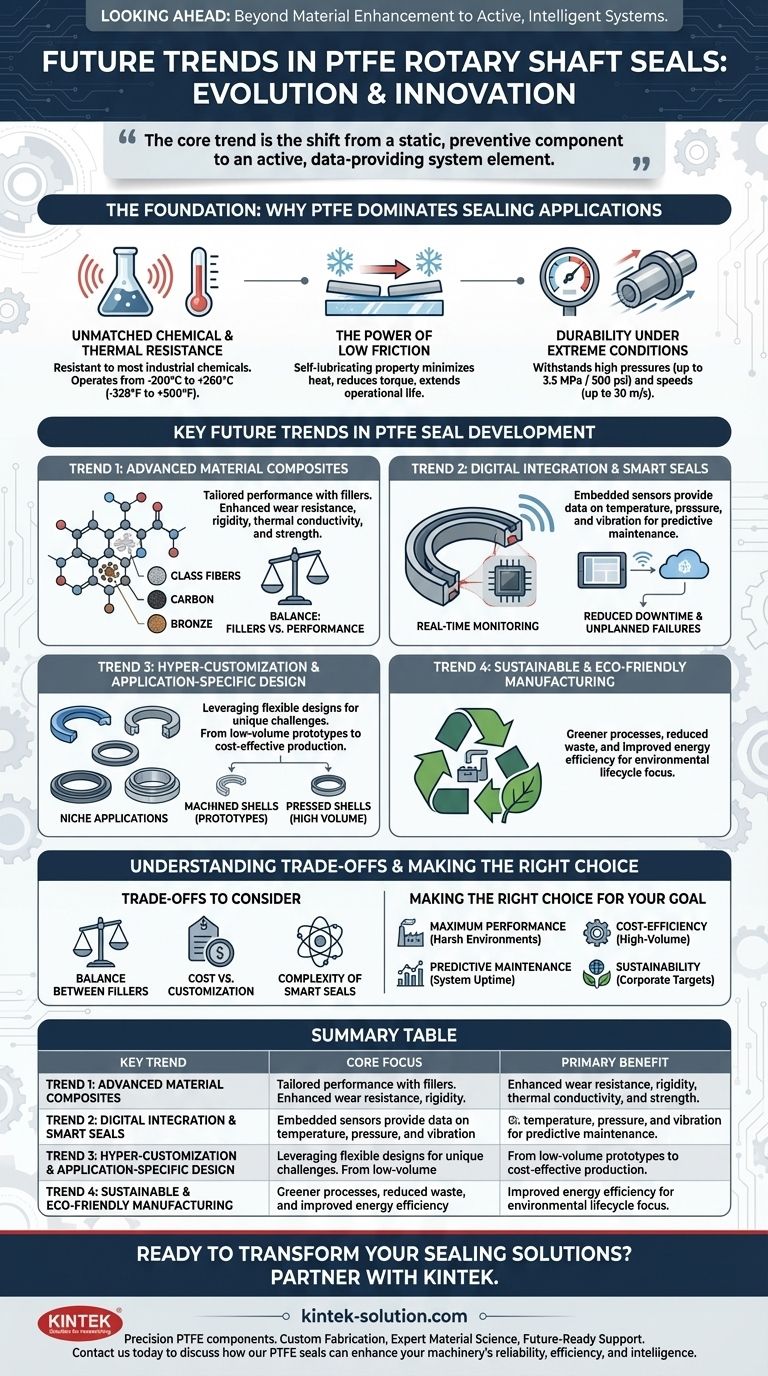

Looking ahead, the evolution of PTFE rotary shaft seals is moving beyond simple material enhancement. Future development is focused on four key areas: creating advanced material composites, integrating digital sensors for real-time monitoring, adopting eco-friendly manufacturing, and delivering hyper-customized solutions for specific industrial challenges. This transforms the seal from a passive component into an active, intelligent part of a larger system.

The core trend is the shift from a static, preventive component to an active, data-providing system element. Seals are no longer just about stopping leaks; they are becoming intelligent, highly specialized, and more sustainable to meet the demands of next-generation machinery.

The Foundation: Why PTFE Dominates Sealing Applications

To understand where PTFE seals are going, we must first understand why they are the material of choice for demanding environments. Their unique combination of properties creates a benchmark that other materials struggle to meet.

Unmatched Chemical and Thermal Resistance

PTFE is exceptionally non-reactive, making it resistant to nearly all industrial chemicals and solvents. This chemical inertness is critical in sectors like chemical processing and pharmaceuticals.

Furthermore, these seals operate effectively across an extreme temperature range, typically from -200°C to +260°C (-328°F to +500°F). This allows them to perform reliably in everything from cryogenic applications to high-heat engines.

The Power of Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This self-lubricating property minimizes heat generation, reduces torque requirements, and allows for dry running in certain applications.

This low-friction nature directly contributes to lower energy consumption and reduced wear on the shaft, extending the operational life of both the seal and the machinery.

Durability Under Extreme Conditions

Standard PTFE seals are engineered to withstand significant pressures, often up to 3.5 MPa (500 psi), and high rotational surface speeds of up to 30 m/s. This makes them indispensable in high-performance hydraulic systems, compressors, and motorsports applications.

Key Future Trends in PTFE Seal Development

The future of PTFE seals is not about replacing the core material but augmenting it with new capabilities. These trends are driven by the increasing demands for efficiency, data, and specialization in modern industry.

Trend 1: Advanced Material Composites

Pure PTFE is excellent, but its performance can be tailored by adding fillers. This trend involves creating sophisticated composites to enhance specific properties for specific tasks.

Common fillers include glass fibers to increase wear resistance and rigidity, carbon to improve thermal conductivity and strength, and bronze to increase compressive strength and thermal dissipation. The future lies in developing novel filler blends for even more precise performance tuning.

Trend 2: Digital Integration and "Smart Seals"

This is arguably the most transformative trend. By embedding miniature sensors directly into or near the seal, it can become an active monitoring device.

These "smart seals" can provide real-time data on temperature, pressure, and vibration. This data feeds into predictive maintenance systems, allowing operators to detect potential failures long before they occur, drastically reducing unplanned downtime.

Trend 3: Hyper-Customization and Application-Specific Design

The "one-size-fits-all" approach is disappearing. Manufacturers are leveraging flexible designs and production methods to create seals for niche applications.

This includes advanced hydrodynamic lip designs that use the shaft's rotation to actively pump fluid away from the seal lip, ensuring tighter sealing at high speeds. It also involves using machined shells for low-volume, highly specialized prototypes and pressed shells for cost-effective, high-volume production runs.

Trend 4: Sustainable and Eco-Friendly Manufacturing

As with all industrial components, there is a growing demand for sustainability. Seal manufacturers are exploring greener manufacturing processes, reducing waste, and improving the energy efficiency of production. This focus on the environmental lifecycle is becoming a key purchasing consideration for many organizations.

Understanding the Trade-offs

While these trends promise significant advances, they come with inherent trade-offs that engineers and designers must consider.

The Balance Between Fillers and Performance

Adding a filler to PTFE is a balancing act. For instance, while adding glass fibers improves wear resistance, it can increase shaft abrasion and may slightly reduce the seal's chemical resistance in certain aggressive media. The choice of composite must be carefully matched to the application's specific chemical and mechanical demands.

Cost vs. Customization

Hyper-customization provides the perfect fit but often comes at a higher initial cost, especially for low-volume runs that require machining instead of pressing. The long-term performance benefits must be weighed against the upfront tooling or engineering charges.

The Complexity of "Smart Seals"

Integrating sensors adds a layer of complexity. It introduces new potential points of failure (the sensor or its wiring), requires a system to collect and interpret the data, and may require a power source. The value of the data must justify this added system complexity.

Making the Right Choice for Your Goal

To navigate these trends, align your selection criteria with your primary objective.

- If your primary focus is maximum performance in a harsh environment: Prioritize advanced material composites and application-specific lip designs to handle extreme temperatures, pressures, or chemicals.

- If your primary focus is predictive maintenance and system uptime: Begin exploring emerging "smart seal" technologies with integrated sensors to gain real-time operational insight.

- If your primary focus is cost-efficiency for a high-volume product: Engage with manufacturers to leverage cost-effective pressed-shell designs and optimize the material for performance without over-engineering.

- If your primary focus is meeting corporate sustainability targets: Inquire specifically about a manufacturer's eco-friendly production processes and the lifecycle impact of their materials.

By understanding these evolving capabilities, you can leverage the humble seal as a key enabler of more reliable, intelligent, and efficient systems.

Summary Table:

| Key Trend | Core Focus | Primary Benefit |

|---|---|---|

| Advanced Material Composites | Tailoring PTFE with fillers (glass, carbon, bronze) | Enhanced wear resistance, strength, and thermal properties for specific tasks |

| Digital Integration & Smart Seals | Embedding sensors for real-time monitoring | Predictive maintenance, reduced downtime via temperature, pressure, and vibration data |

| Hyper-Customization | Application-specific designs (e.g., hydrodynamic lips) | Optimal sealing for niche challenges, from prototypes to high-volume orders |

| Sustainable Manufacturing | Eco-friendly processes and reduced waste | Lower environmental impact, aligning with corporate sustainability goals |

Ready to Transform Your Sealing Solutions?

As PTFE seals evolve into intelligent, custom components, partnering with the right manufacturer is critical. KINTEK specializes in precision PTFE components—including advanced rotary shaft seals—for the semiconductor, medical, laboratory, and industrial sectors. We offer:

- Custom Fabrication: From prototypes to high-volume orders, tailored to your exact needs.

- Expert Material Science: Access to advanced composites that balance performance, durability, and cost.

- Future-Ready Support: Guidance on trends like smart seals and sustainability to keep your systems ahead.

Contact us today to discuss how our PTFE seals can enhance your machinery’s reliability, efficiency, and intelligence. Let’s build the future of sealing together.

Get in touch now to start your project!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What makes machined PTFE suitable for industrial applications? Unmatched Performance in Extreme Conditions

- What are the key benefits of PTFE coatings? Achieve Unmatched Performance in Extreme Conditions

- What are the uses of Polytetrafluoroethylene (PTFE) with Glass Fill? Boost Wear Resistance & Strength

- What makes PTFE an excellent material for insulation in wires and cables? Unmatched Performance for Extreme Conditions

- What are the different types of PTFE gaskets? A Guide to Choosing the Right Seal

- What is the function of PTFE machined bellows? A Guide to Protecting Critical Systems

- How do PTFE rods contribute to energy efficiency in industrial applications? Reduce Friction & Power Consumption

- What is the conclusion about PTFE-coated O-rings? A Guide to Their Limited, Specific Use Cases