In its most common applications, expanded Polytetrafluoroethylene (ePTFE) is primarily available as a flexible cord, sealing tape, gasket material, or tubing. These forms are specifically designed to leverage the material's unique microporous structure for demanding sealing and filtration tasks across industrial and medical fields.

The specific form of ePTFE is not just a matter of shape, but a direct consequence of its manufacturing process. The "expansion" creates a porous, strong, and highly conformable material, making it an exceptional solution for applications where standard solid plastics would fail.

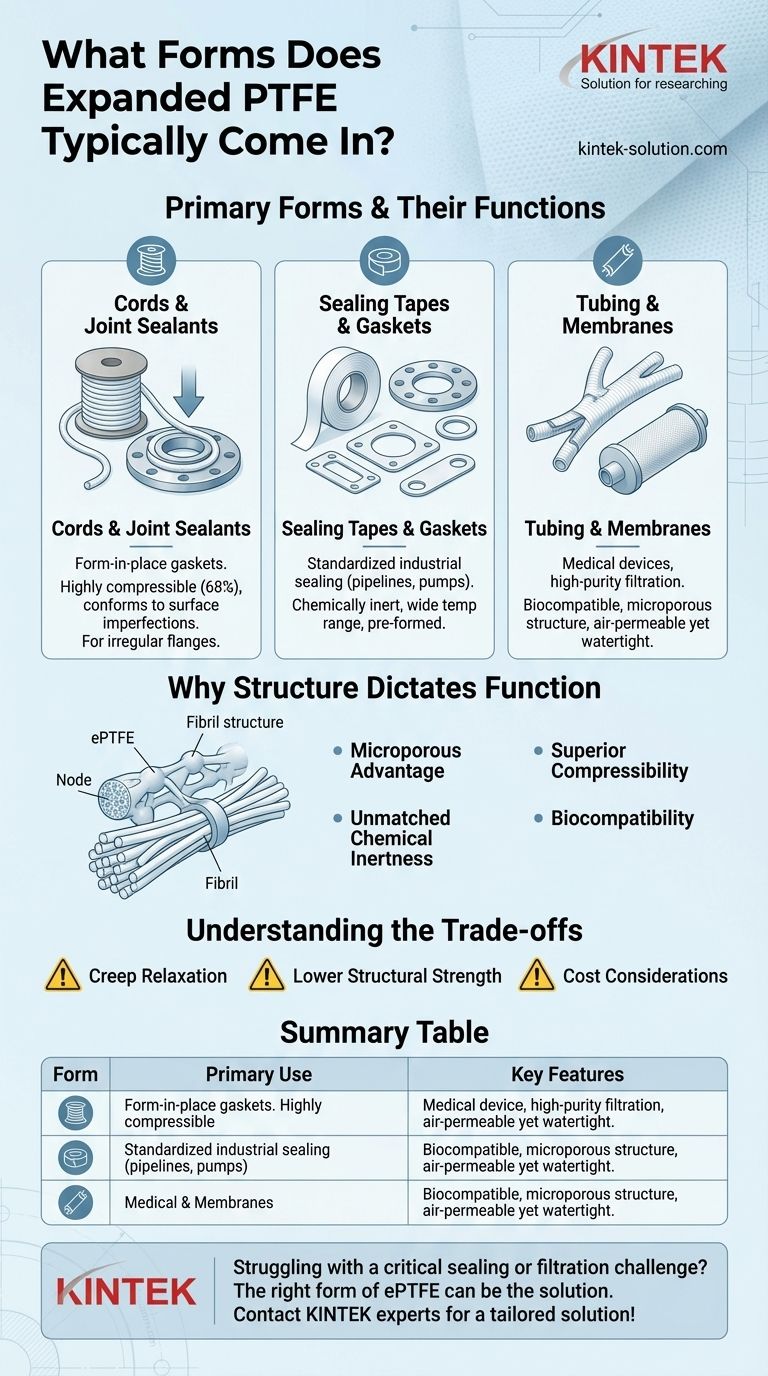

The Primary Forms and Their Functions

Expanded PTFE's versatility comes from its ability to be shaped for very specific uses. Each form is optimized for a particular type of application, from creating custom gaskets on industrial equipment to building biocompatible medical implants.

Cords and Joint Sealants

This form looks like a rope or cord and is often supplied on a spool with an adhesive backing on one side. It is a "form-in-place" gasket.

You press the cord onto a flange surface, cut it to length, and overlap the ends. When the flange is tightened, the highly compressible ePTFE cord flattens to create a perfect, custom-fit seal that fills in surface imperfections.

Sealing Tapes and Gaskets

ePTFE is frequently cut from sheets into standardized gaskets or provided as a thin tape. This is ideal for sealing flange joints in common systems.

These pre-formed shapes are used in pipelines, hydraulic and pneumatic systems, and chemical processing equipment. They provide a reliable seal that is resistant to virtually all chemicals and can withstand a wide range of temperatures.

Tubing and Membranes

In this form, ePTFE is used for its combination of chemical inertness, biocompatibility, and controlled porosity. It is a critical material for advanced applications.

Medical devices, such as vascular grafts, rely on ePTFE tubing for its non-toxic and non-allergenic properties. Its microporous structure also makes it an excellent material for high-performance filters and electronic insulators.

Why Structure Dictates Function

Understanding the forms of ePTFE requires understanding the material itself. Unlike solid PTFE, ePTFE consists of solid nodes connected by a web of microscopic fibrils. This unique structure is what gives the material its most valuable properties.

The Microporous Advantage

The space between the fibrils allows ePTFE to be permeable to air while remaining watertight at low pressures. This characteristic is essential for advanced filtration and venting applications.

Superior Compressibility and Sealability

The fibrous structure allows ePTFE to compress easily under load, conforming to scratches and irregularities on sealing surfaces. With a compressibility of 68%, it creates an extremely tight seal where rigid materials would leak.

Unmatched Chemical Inertness

Like standard PTFE, ePTFE is chemically inert and resistant to almost all industrial chemicals. This makes it a go-to choice for sealing flanges in the oil and gas, chemical, and pharmaceutical industries where corrosive materials are common.

Biocompatibility for Medical Use

ePTFE is non-toxic, non-cancerous, and well-tolerated by the human body. This biocompatibility makes its tubing and membrane forms invaluable for life-saving medical devices and implants.

Understanding the Trade-offs

While ePTFE is a high-performance material, it's essential to understand its limitations to use it effectively. Its strengths in sealing and flexibility come with trade-offs in mechanical properties.

Creep Relaxation

ePTFE exhibits creep, meaning it can slowly deform over time when under a constant load, especially at elevated temperatures. The references note a creep relaxation of 32% at 212°F (100°C), which must be accounted for in the design of critical bolted joints.

Lower Structural Strength

With a tensile strength around 1600 psi, ePTFE is not a structural material. It is designed to seal, not to bear significant mechanical loads. Its purpose is to sit between two stronger structural components and create a barrier.

Cost Considerations

As a specialized, high-performance polymer, ePTFE is typically more expensive than conventional gasketing materials like rubber or fiber composites. Its use is justified when performance, chemical resistance, and reliability are non-negotiable.

Selecting the Right Form for Your Application

Choosing the correct form of ePTFE is crucial for success. Your decision should be guided by the specific demands of your project.

- If your primary focus is sealing irregular or large flanges: Use ePTFE cord or joint sealant for its unmatched form-in-place flexibility and ability to create a custom gasket.

- If your primary focus is standardized industrial sealing: Use pre-cut ePTFE gaskets or tapes for reliable, repeatable performance in pipelines, pumps, or hydraulic systems.

- If your primary focus is medical devices or high-purity filtration: Use ePTFE tubing or membranes to leverage the material's unique biocompatibility and controlled microporous structure.

By matching the form of ePTFE to your specific goal, you can fully leverage its unique capabilities for your most demanding engineering challenges.

Summary Table:

| Form | Primary Use | Key Features |

|---|---|---|

| Cords & Joint Sealants | Form-in-place gaskets for irregular flanges | Highly compressible (68%), conforms to surface imperfections |

| Sealing Tapes & Gaskets | Standardized industrial sealing (pipelines, pumps) | Chemically inert, wide temperature range, pre-formed |

| Tubing & Membranes | Medical devices, high-purity filtration | Biocompatible, microporous structure, air-permeable yet watertight |

Struggling with a critical sealing or filtration challenge? The right form of expanded PTFE (ePTFE) can be the solution. At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom ePTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Whether you need a prototype or a high-volume order, our expertise ensures you get a component that delivers superior chemical resistance, reliability, and performance. Let's discuss your specific application requirements – contact our experts today for a tailored solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications