In short, machining Polytetrafluoroethylene (PTFE) is a specialized process that requires careful management of its unique properties. Unlike metals, PTFE is soft, expands significantly with heat, and can deform under pressure, necessitating specific tools, coolants, and operating parameters like controlled speeds, feeds, and shallow cuts to achieve precision.

The central challenge in machining PTFE is not cutting the material, but controlling its response to heat and pressure. Success hinges on minimizing thermal expansion and physical deformation through sharp tooling, aggressive cooling, and minimal clamping force.

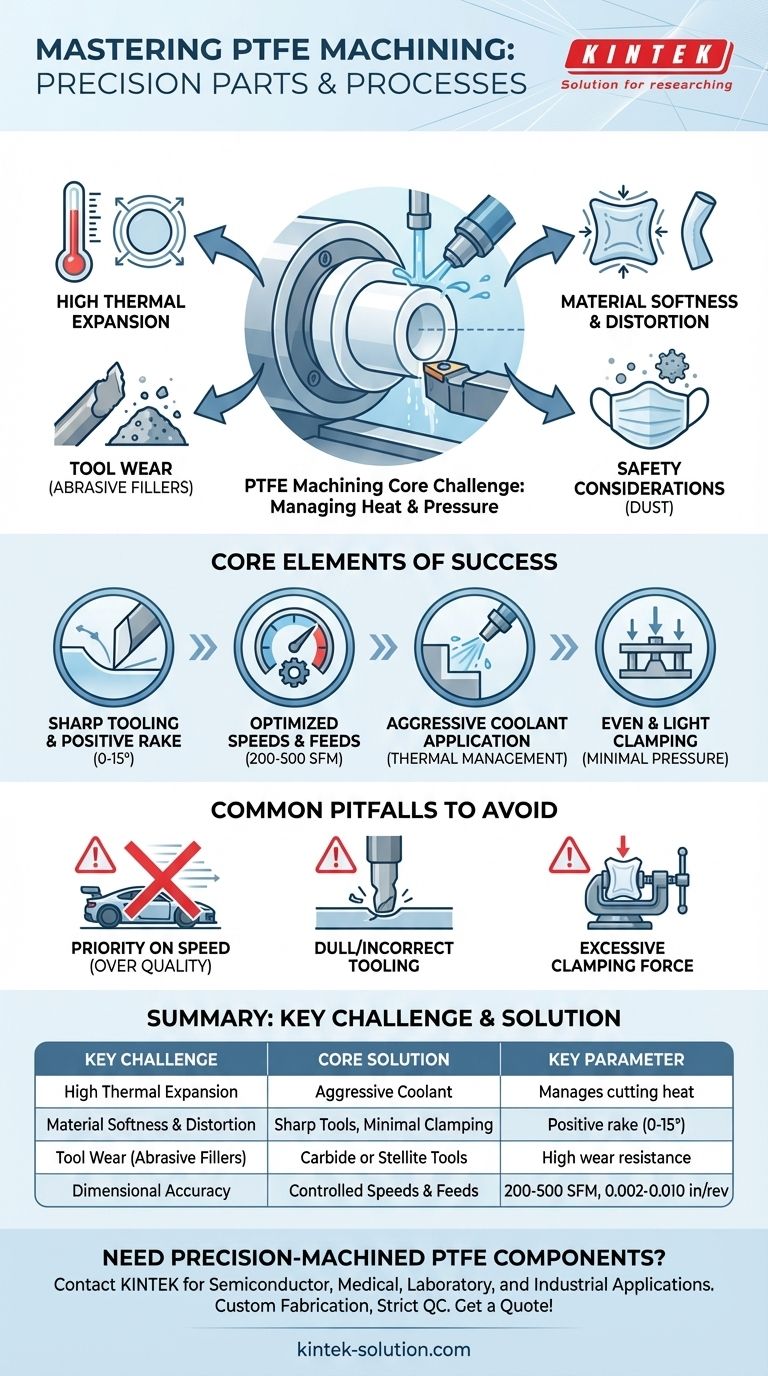

Understanding PTFE's Unique Machining Challenges

To machine PTFE effectively, you must first understand why it behaves differently from other materials. Its core properties present distinct challenges that dictate every aspect of the process.

High Thermal Expansion

PTFE has a very high coefficient of thermal expansion. The friction from a cutting tool generates heat, which causes the material to expand immediately. This can easily throw off dimensional accuracy, resulting in an out-of-spec part once it cools.

Material Softness and Distortion

PTFE is a soft material with low rigidity. It can easily be compressed or deformed by excessive clamping pressure in a fixture or by the force of a dull cutting tool. This makes securing the workpiece without distortion a primary concern.

Tool Wear

While pure PTFE is relatively easy to cut, many grades are filled with materials like glass, carbon, or bronze to enhance their mechanical properties. These fillers can be highly abrasive and will wear down cutting tools quickly, leading to poor surface finish and dimensional inaccuracy.

Safety Considerations

The machining process creates fine PTFE dust. These micro-particles can be a health hazard if inhaled, making it crucial to use a coolant system to suppress dust or for the operator to wear a mask.

The Core Elements of Successful PTFE Machining

A successful outcome depends on a systematic approach that directly counteracts PTFE's challenging characteristics.

Tool Selection is Paramount

The right tool does most of the work. Stellite-tipped or carbide tools are ideal due to their hardness and wear resistance, especially for filled PTFE grades.

Crucially, tools must be extremely sharp with a positive top rake (typically between 0 and 15 degrees). A sharp edge with a positive rake slices cleanly through the material, reducing cutting forces and minimizing heat generation and material deformation.

Optimizing Speeds and Feeds

Precise control over speeds and feeds is essential for managing heat. Recommended parameters vary but generally fall within a cutting speed of 200 to 500 surface feet per minute (SFM) and a feed rate of 0.002 to 0.010 inches per revolution.

The goal is to find a balance that removes material efficiently without allowing heat to build up in the part. Slower speeds and controlled feed rates often provide the best results for finish and accuracy.

The Critical Role of Coolant

A generous supply of coolant is non-negotiable. Its primary purpose is not lubrication but thermal management. Coolant actively pulls heat away from the workpiece and the cutting tool, preventing the thermal expansion that ruins dimensional stability. It also helps flush away chips and suppress hazardous dust.

Fixture Design and Clamping

How you hold the workpiece is as important as how you cut it. Fixtures must be designed to distribute clamping pressure evenly and lightly. Overtightening a clamp will immediately compress the soft PTFE, leading to a distorted part as soon as it is released.

Common Pitfalls to Avoid

Mistakes in PTFE machining almost always trace back to a failure to respect the material's core properties.

Prioritizing Speed Over Quality

Attempting to machine PTFE with the same aggressive parameters used for aluminum is a common error. This approach generates excessive heat, causing the part to expand during the cut and finish undersized once it cools.

Using Dull or Incorrect Tooling

A dull tool, or one without a positive rake, will plow or push material instead of shearing it. This creates a poor surface finish, introduces stress into the part, and increases heat buildup. Regular tool inspection and resharpening are vital.

Applying Excessive Clamping Force

Technicians accustomed to rigidly clamping metals can easily make the mistake of overtightening fixtures for PTFE. This is a primary cause of deformed or out-of-tolerance parts, as the material "springs back" once released.

Making the Right Choice for Your Goal

Your final approach should be dictated by the most critical requirement for your component.

- If your primary focus is dimensional accuracy: Prioritize aggressive cooling and minimal, evenly distributed clamping pressure above all else.

- If your primary focus is a high-quality surface finish: Use extremely sharp, polished tools with a positive rake and opt for slower, more controlled feed rates.

- If your primary focus is balancing production speed and quality: Invest in premium carbide tooling and find the maximum speed that does not introduce thermal instability, monitoring part dimensions closely.

Mastering PTFE machining means respecting the material's inherent sensitivity and prioritizing thermal and physical stability over raw cutting speed.

Summary Table:

| Key Challenge | Core Solution | Key Parameter |

|---|---|---|

| High Thermal Expansion | Aggressive Coolant Application | Manages cutting heat |

| Material Softness & Distortion | Sharp Tools, Minimal Clamping | Positive rake angle (0-15°) |

| Tool Wear (Abrasive Fillers) | Carbide or Stellite Tools | High wear resistance |

| Dimensional Accuracy | Controlled Speeds & Feeds | 200-500 SFM, 0.002-0.010 in/rev |

Need precision-machined PTFE components that meet exact specifications?

At KINTEK, we specialize in machining PTFE and other high-performance polymers for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in managing material properties like thermal expansion and softness ensures your seals, liners, and labware are produced with exceptional dimensional accuracy and surface finish.

We offer custom fabrication from prototypes to high-volume orders, leveraging sharp tooling, optimized parameters, and rigorous quality control.

Contact KINTEK today to discuss your PTFE machining project and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech