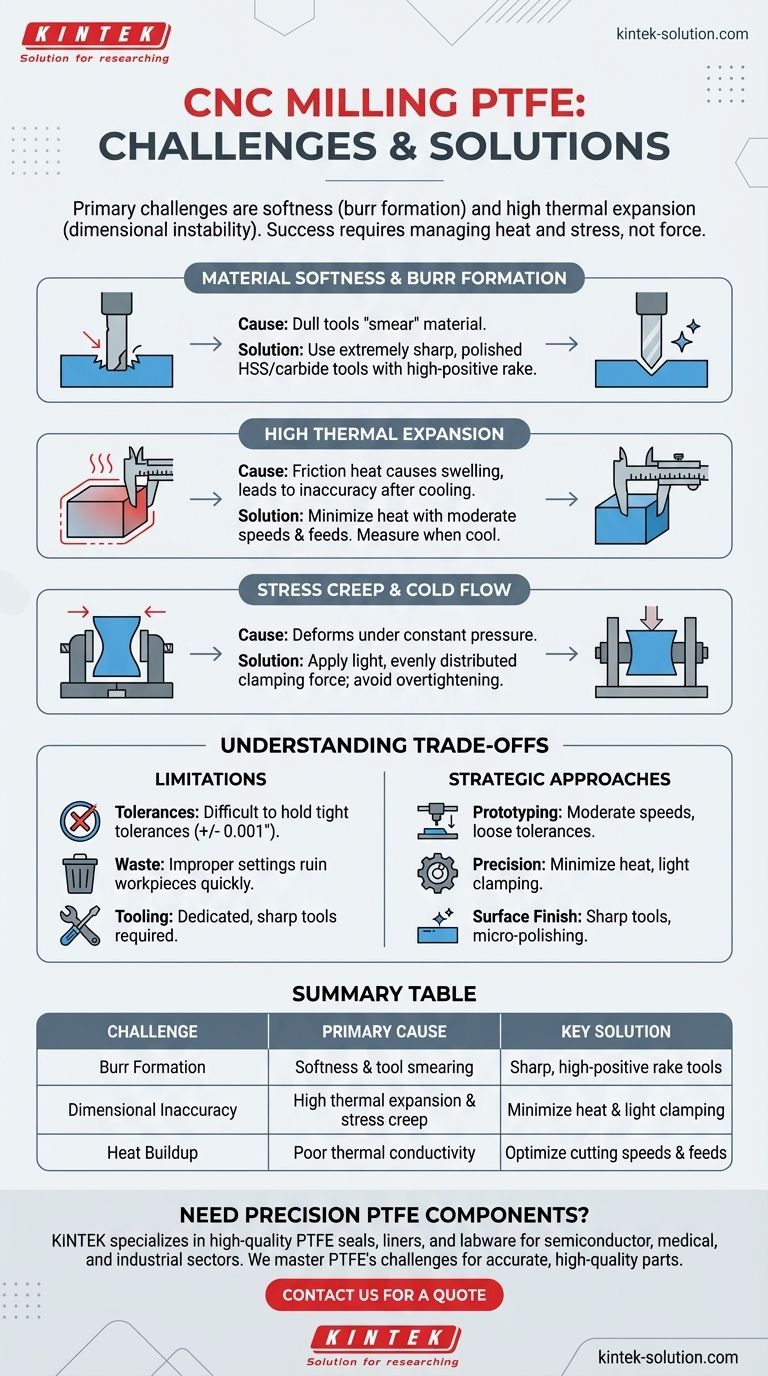

The primary challenges in CNC milling PTFE are its softness, which leads to burr formation, and its high coefficient of thermal expansion, which causes dimensional instability. Successfully machining Polytetrafluoroethylene (PTFE) requires a strategy that accommodates these inherent material properties with specific tools, settings, and handling techniques.

The core difficulty in machining PTFE is not its hardness, but its tendency to deform under heat and pressure. Success depends on working with the material's nature by managing thermal expansion and mechanical stress, rather than trying to force it into submission.

The Core Problem: Why PTFE Behaves Differently

To understand the challenges of milling PTFE, you must first understand its fundamental properties. Unlike rigid metals or plastics, PTFE's behavior under stress and heat dictates the entire machining strategy.

Unpacking PTFE's Softness

PTFE is an exceptionally soft material. During milling, a dull or improperly designed cutting tool will tend to push or "smear" the material rather than shearing it cleanly.

This pushing action is the primary cause of heavy burring, which results in a poor surface finish and requires secondary deburring operations.

The High Coefficient of Thermal Expansion

PTFE expands and contracts with temperature changes far more than most materials. The friction from a cutting tool generates localized heat, causing the material to swell during the milling process.

If dimensions are measured while the part is still warm, it will be out of specification once it cools and shrinks. This makes achieving dimensional accuracy a significant challenge.

Stress Creep and Cold Flow

PTFE is prone to "stress creep," also known as cold flow. This means the material will slowly deform over time when subjected to a constant pressure, even at room temperature.

This property directly impacts workholding. If a workpiece is clamped too tightly in a vise, it will compress. The part may be perfectly dimensioned while clamped, but it will be inaccurate once the pressure is released and the material relaxes.

Practical Machining Challenges and Solutions

These material properties create predictable problems on the shop floor. Addressing them requires specific adjustments to standard milling practices.

Achieving Dimensional Accuracy

The combination of thermal expansion and stress creep makes holding tight tolerances difficult. The key is to minimize heat generation and clamping pressure.

Use moderate cutting speeds and feeds to reduce friction and heat buildup. This is the single most effective way to manage thermal expansion.

Preventing Burr Formation

To get a clean cut instead of a smeared one, the cutting tool is paramount. Use extremely sharp and polished cutting tools, preferably made from High-Speed Steel (HSS) or uncoated carbide.

A high-positive rake angle on the tool helps lift the chip and shear the material cleanly, drastically reducing burr formation.

Managing Heat Buildup

Because PTFE is a poor thermal conductor, heat concentrates at the cutting edge. If not managed, this localized heat leads directly to the expansion issues previously mentioned.

Coolants can help, but the first line of defense is always a sharp tool and appropriate cutting speeds to prevent the heat from being generated in the first place.

Securing the Workpiece Without Distortion

To counteract stress creep, apply just enough clamping force to hold the part securely. Avoid overtightening at all costs.

Using fixtures with a larger surface area to distribute the clamping pressure can also help prevent the material from compressing and deforming.

Understanding the Trade-offs

While PTFE's properties make it ideal for certain applications like low-friction seals or chemical-resistant components, they also introduce unavoidable limitations.

The Tolerance Limitation

Due to its inherent instability, PTFE is not well-suited for parts requiring extremely tight tolerances (e.g., +/- 0.001"). Designs must account for this by specifying more generous tolerances where possible.

The Risk of Material Waste

Improper settings can ruin a PTFE workpiece quickly. The initial setup and test cuts are critical to dial in the correct parameters, which may lead to some initial material scrap.

The Need for Dedicated Tooling

While PTFE is easy to cut in principle, achieving a quality result requires specific tooling. Tools must be kept exceptionally sharp and should ideally be dedicated only to machining soft plastics to avoid nicks or dulling that would degrade performance.

Making the Right Choice for Your Goal

Your approach to machining PTFE should align directly with your project's final objective.

- If your primary focus is rapid prototyping: Leverage PTFE's easy machinability with moderate speeds, but design with loose tolerances in mind.

- If your primary focus is high-precision components: You must prioritize minimizing heat with sharp tools and controlled cutting speeds, while using low and evenly distributed clamping pressure.

- If your primary focus is a superior surface finish: Use exceptionally sharp, high-positive rake tools and consider secondary operations like micro-polishing after milling.

Ultimately, successful PTFE machining comes from respecting the material's unique properties, not fighting them.

Summary Table:

| Challenge | Primary Cause | Key Solution |

|---|---|---|

| Burr Formation | Material softness & tool smearing | Use sharp, high-positive rake tools |

| Dimensional Inaccuracy | High thermal expansion & stress creep | Minimize heat & use light clamping |

| Heat Buildup | PTFE's poor thermal conductivity | Optimize cutting speeds & feeds |

Need precision-machined PTFE components?

At KINTEK, we specialize in manufacturing high-quality PTFE seals, liners, and labware for the semiconductor, medical, and industrial sectors. Our expertise in custom fabrication allows us to expertly navigate the challenges of PTFE's softness and thermal expansion, delivering parts with the dimensional accuracy and superior surface finish your application demands—from prototypes to high-volume production.

Contact our team today to discuss your project requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What is a PTFE coated O-ring? A Hybrid Seal for Low Friction & Chemical Resistance

- What is the significance of the insulation performance of PTFE gaskets? Ensure Safety & Reliability

- What improvements do 25% carbon-filled PTFE bushings offer? Boost Strength, Wear & Static Dissipation

- What additional properties do PTFE O-rings require besides thermal resistance? Master Chemical and Mechanical Sealing

- What are the advantages of using ePTFE sheets for gaskets? Superior Sealing for Demanding Conditions

- What advantages do PTFE valve seat rings offer? Achieve Superior Sealing in Demanding Environments

- What makes PTFE O-rings durable over time? The Secret to Long-Lasting Seals in Harsh Conditions

- What are the three primary application areas for PTFE O-rings? Master Sealing in Harsh Environments