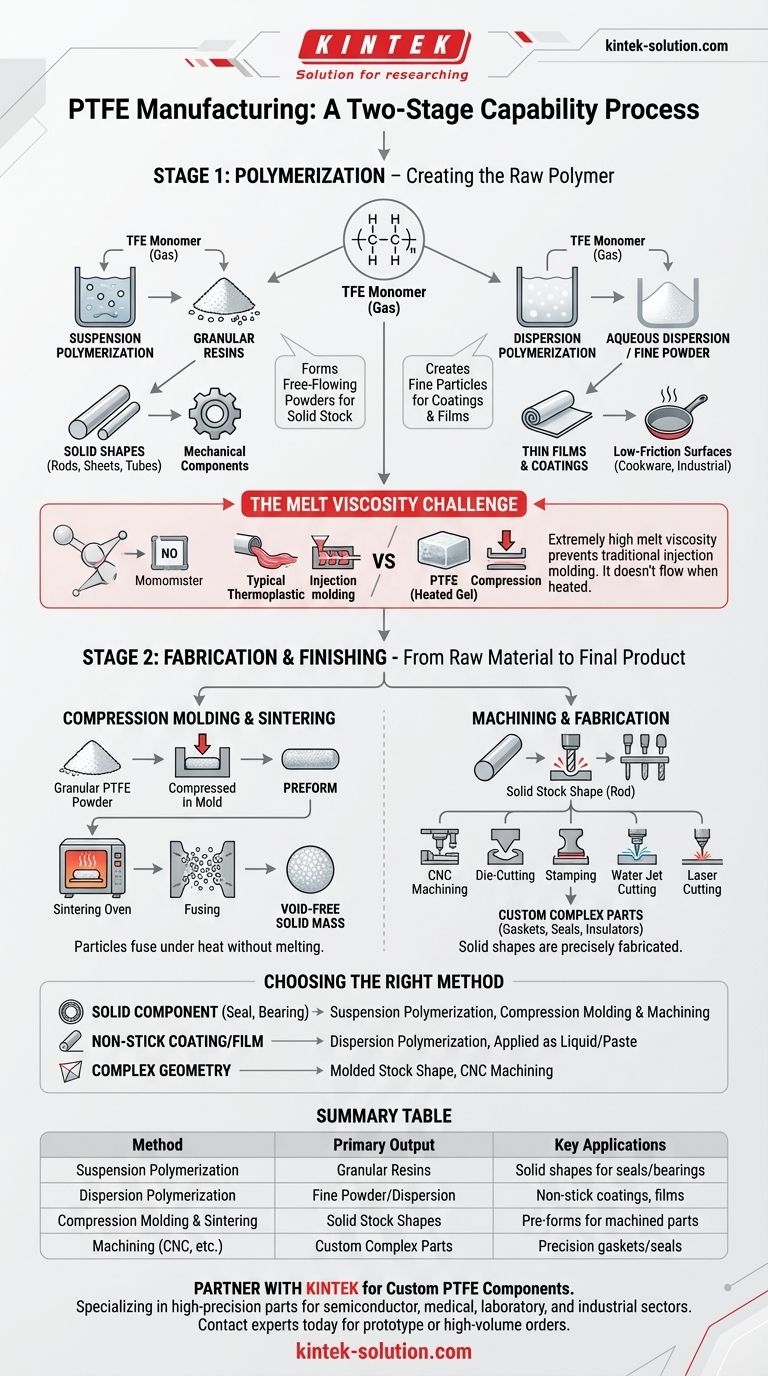

The manufacturing capabilities for PTFE are a two-stage process. First, the raw polymer is created using one of two primary methods—suspension or dispersion polymerization—which produce either solid granules or a fine paste. Second, this raw material is then formed into a final product through specialized techniques like compression molding, sintering, and machining, as its unique properties prevent traditional injection molding.

The core challenge in PTFE manufacturing is its extremely high melt viscosity; it doesn't flow like other plastics when heated. This fundamental limitation dictates a unique set of production and fabrication methods centered on compressing and fusing powders rather than melting and injecting.

The Two Pillars of PTFE Production

The journey from a chemical monomer to a finished part begins with polymerization. The chosen method at this initial stage determines the physical form of the raw PTFE and, consequently, its primary applications.

Suspension Polymerization for Solid Shapes

This process polymerizes the TFE monomer in water, resulting in granular PTFE resins. These grains are typically processed into free-flowing powders or pellets.

This granular form is the precursor for creating solid stock shapes like rods, sheets, and tubes, which are used for mechanical and structural components.

Dispersion Polymerization for Coatings and Films

In this method, the polymerization process results in a milky, aqueous dispersion containing very fine PTFE particles. This can be used as-is or processed further into a fine powder.

This form of PTFE is ideal for creating thin films and non-stick coatings, famously used on cookware and in various industrial applications requiring a low-friction surface.

The Foundation: The TFE Monomer

Both production pathways begin with the same building block: tetrafluoroethylene (TFE). This colorless, odorless gas is the monomer that is chemically linked together in long chains to form the stable, non-reactive polymer we know as PTFE.

From Raw Polymer to Final Part

Once the raw PTFE resin exists, it must be converted into a usable product. Because of its properties, the methods used are distinct from those for common thermoplastics.

Compression Molding and Sintering

This is the primary method for processing granular PTFE from suspension polymerization. The powder is compressed under high pressure in a mold to form a preform shape.

This preform is then heated in a controlled oven in a process called sintering. The temperature is raised above PTFE's melting point, causing the individual particles to fuse together into a solid, void-free mass without the material ever truly liquefying.

Machining and Fabrication

Once solid stock shapes are created through molding and sintering, they can be precisely fabricated into custom parts. PTFE is readily machinable, similar to a soft metal.

Common fabrication capabilities include CNC machining, die-cutting, stamping, water jet cutting, and laser cutting to produce complex geometries for components like gaskets, seals, and insulators.

Understanding the Critical Limitation

The choice of these manufacturing methods is not arbitrary; it's a direct consequence of PTFE's inherent chemical nature.

Why PTFE Cannot Be Injection Molded

Unlike plastics like polyethylene or polycarbonate, PTFE has an exceptionally high melt viscosity. When heated past its melting point, it does not become a free-flowing liquid that can be easily injected into a mold cavity.

Instead, it transforms into a transparent but firm gel-like substance that does not flow. This behavior makes conventional melt-processing techniques like injection molding and extrusion impractical, necessitating the compress-and-sinter approach.

Making the Right Choice for Your Goal

The required manufacturing capability depends entirely on the final application.

- If your primary focus is a solid component like a seal, bearing, or insulator: Your part will be made from suspension-polymerized resin that is compression molded and then machined to final specifications.

- If your primary focus is a non-stick coating or a thin film: Your application requires dispersion-polymerized PTFE applied as a liquid paste or spray.

- If your primary focus is a highly precise, complex geometry: The process will start with a molded stock shape (a rod or sheet) which is then fabricated using a secondary method like CNC machining.

Understanding these distinct manufacturing pathways is the key to correctly specifying and sourcing a PTFE component that meets your performance requirements.

Summary Table:

| Method | Primary Output | Key Applications |

|---|---|---|

| Suspension Polymerization | Granular Resins | Solid shapes (rods, tubes) for seals, bearings, insulators |

| Dispersion Polymerization | Fine Powder / Aqueous Dispersion | Non-stick coatings, thin films |

| Compression Molding & Sintering | Solid Stock Shapes | Pre-forms for machined components |

| Machining (CNC, etc.) | Custom, Complex Parts | Precision gaskets, seals, and labware |

Need a custom PTFE component for your application?

At KINTEK, we specialize in manufacturing high-precision PTFE components—from seals and liners to custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in both polymerization and fabrication methods ensures you get a part perfectly suited to your performance requirements, whether it's a prototype or a high-volume order.

Contact our experts today to discuss your project and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining