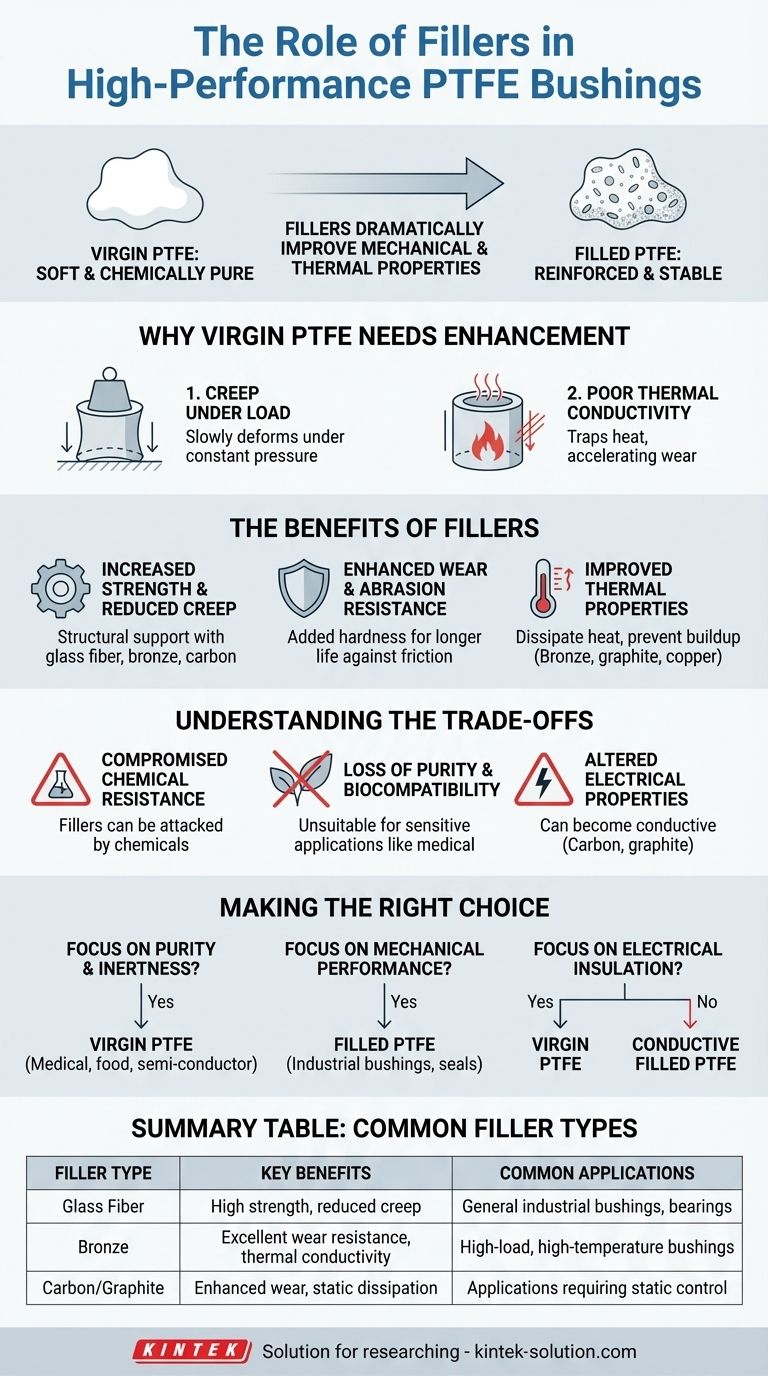

In short, fillers are added to virgin PTFE to dramatically improve its mechanical and thermal properties for demanding applications like bushings. While virgin PTFE is exceptionally slick and chemically resistant, it is also soft and prone to deforming under pressure. Fillers act as a reinforcement, providing the strength, wear resistance, and heat dissipation that virgin material lacks.

The core purpose of adding fillers to PTFE is to overcome its inherent softness and tendency to creep under load. You are essentially trading the absolute chemical purity of virgin PTFE for vastly superior mechanical strength and dimensional stability.

Why Virgin PTFE Needs Enhancement for Bushings

To understand the role of fillers, we must first appreciate the limitations of virgin PTFE in mechanical systems. While its properties are remarkable, they are not universally suited for every task.

The Challenge of "Creep"

Virgin PTFE is a relatively soft material. When subjected to a constant load, especially at elevated temperatures, it has a tendency to "creep," or slowly deform over time.

For a bushing, which must maintain precise dimensions to function correctly, this deformation can lead to a loss of tolerance and eventual failure.

Poor Thermal Conductivity

PTFE is an excellent thermal insulator. In a dynamic application like a bushing, friction generates heat. Virgin PTFE's inability to dissipate this heat can cause it to build up, which accelerates both wear and creep.

The Core Mechanical and Thermal Improvements from Fillers

Fillers are chosen specifically to counteract the weaknesses of the base PTFE material. They are mixed into the PTFE resin before it's molded, creating a composite material with enhanced characteristics.

Increased Strength and Reduced Creep

Fillers like glass fiber, bronze, and carbon create a reinforcing matrix within the PTFE. This matrix provides structural support, significantly increasing the material's compressive strength and its ability to resist deformation under a sustained load.

Enhanced Wear and Abrasion Resistance

The same reinforcing fillers add hardness and durability to the soft PTFE. This dramatically improves the bushing's resistance to physical wear from rotating shafts or sliding surfaces, leading to a much longer service life.

Improved Thermal Properties

Fillers such as bronze, graphite, and copper have much higher thermal conductivity than PTFE. Their inclusion creates a pathway for heat to escape from the bearing surface, preventing thermal buildup and maintaining the bushing's stability at higher temperatures.

Understanding the Trade-offs: What You Sacrifice

Adding fillers is not a universal upgrade. These enhancements come at the cost of some of virgin PTFE's most valued original properties, a critical consideration for material selection.

Compromised Chemical Resistance

While PTFE is nearly chemically inert, many fillers are not. A filler like glass, for instance, can be attacked by strong alkalis or hydrofluoric acid. The filler material can create a weak point, reducing the composite's overall chemical resistance compared to virgin PTFE.

Loss of Purity and Biocompatibility

Virgin PTFE is prized in medical, pharmaceutical, and food-processing industries for its purity and inertness. The introduction of any filler negates this, making filled PTFE unsuitable for applications like medical implants or components in direct contact with sensitive products.

Altered Electrical Properties

Virgin PTFE is an outstanding electrical insulator. However, adding conductive fillers like carbon or graphite transforms it into a material that can dissipate static electricity. While this is a benefit for some applications, it makes the material unsuitable for high-voltage insulation.

Making the Right Choice for Your Goal

The decision between virgin and filled PTFE is entirely dependent on the primary demands of your application.

- If your primary focus is chemical purity and inertness: Stick with virgin PTFE for applications in medical, food, or semiconductor manufacturing.

- If your primary focus is mechanical performance under load: A filled PTFE is the superior choice for most industrial bushings, bearings, and seals.

- If your primary focus is electrical insulation: Virgin PTFE is the correct material, unless you specifically require static dissipation, which calls for a conductive filler.

By understanding this fundamental trade-off between purity and strength, you can confidently select the right material for your specific engineering challenge.

Summary Table:

| Filler Type | Key Benefits | Common Applications |

|---|---|---|

| Glass Fiber | High strength, reduced creep | General industrial bushings, bearings |

| Bronze | Excellent wear resistance, thermal conductivity | High-load, high-temperature bushings |

| Carbon/Graphite | Enhanced wear, static dissipation | Applications requiring static control |

Need a high-performance PTFE bushing solution tailored to your specific mechanical and environmental demands? KINTEK specializes in manufacturing custom PTFE components, including bushings, seals, and liners, for the semiconductor, medical, laboratory, and industrial sectors. We use precision production to ensure your parts meet exact specifications, whether you need a prototype or a high-volume order. Contact our experts today to discuss how our filled or virgin PTFE solutions can enhance your application's performance and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How is the coefficient of friction for PTFE measured? A Guide to Precise Friction Data

- What are the advantages of PTFE seals? Superior Performance in Extreme Chemical and Thermal Environments

- How is PTFE utilized in the electrical and electronics industry? Unlock Superior Performance & Reliability

- What are the main types of spring-energized PTFE seals? A Guide to Sealing Force & Friction

- What environmental conditions can Teflon seals withstand? Master Extreme Temperatures & Chemicals

- What factors should be considered when choosing between NBR and PTFE seat materials for butterfly valves?

- What are some common PTFE seal types used in industrial applications? Explore Solutions for Every Motion & Environment

- What makes PTFE gaskets an excellent choice for compressors? Unlock Superior Sealing Performance