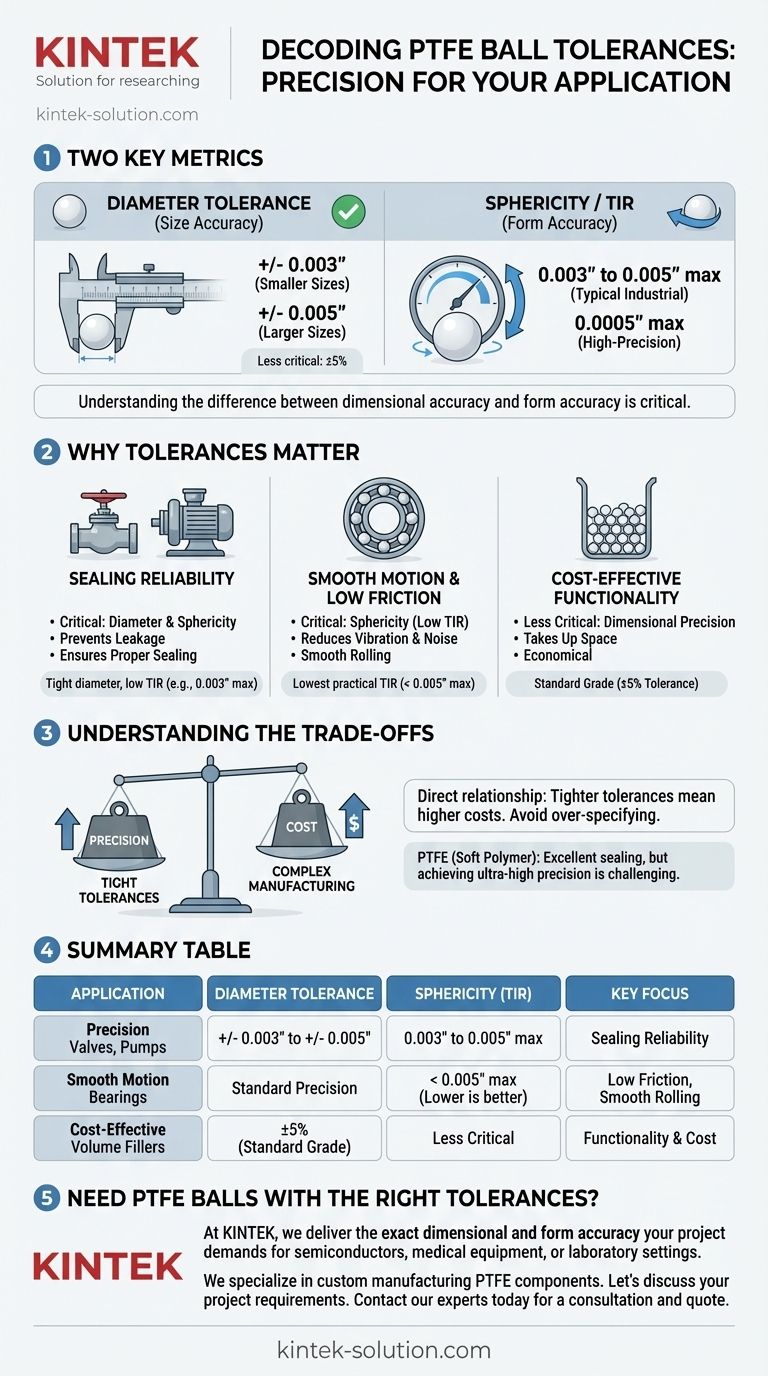

For a typical industrial application, the diameter tolerance for a PTFE ball is generally between +/- 0.003 inches for smaller sizes and +/- 0.005 inches for larger sizes. Sphericity, measured as Total Indicator Reading (TIR), is often held to a maximum of 0.003 to 0.005 inches. However, less critical applications may use a much wider standard tolerance, such as ±5% of the diameter.

The tolerance of a PTFE ball is not a single standard but a specification driven by your application's needs. Understanding the difference between dimensional accuracy (diameter tolerance) and form accuracy (sphericity) is critical to avoiding over-engineering and unnecessary costs.

Decoding PTFE Ball Tolerances

The numbers provided for tolerance define two separate, but equally important, geometric characteristics of the ball: its size and its roundness. Confusing these can lead to specifying the wrong part for your system.

Diameter Tolerance (Size Accuracy)

This is the most commonly cited tolerance. It specifies the allowable variation from the nominal or target diameter of the ball.

PTFE balls are often available in two general grades:

- Precision Grade: For applications like valves or bearings, a tight tolerance of +/- 0.003" to +/- 0.005" is standard.

- Standard Grade: For less demanding uses like volume displacement, a much looser tolerance of ±5% is often acceptable and more economical.

Sphericity / TIR (Form Accuracy)

This tolerance, also called roundness, defines how closely the ball conforms to a perfect sphere. It is often measured as Total Indicator Reading (TIR).

A lower TIR value indicates a more perfectly round ball. A typical industrial-grade ball may have a TIR of 0.003" to 0.005" max. High-precision applications might specify a TIR as low as 0.0005" max to ensure perfectly smooth motion or sealing.

The Role of Ball Size

As a general manufacturing principle, it is often easier to hold tighter absolute tolerances on smaller parts.

Therefore, you will frequently see specifications where smaller diameter PTFE balls have a tighter diameter tolerance (e.g., +/- 0.003") than larger diameter balls (e.g., +/- 0.005").

Why These Tolerances Matter for Your Application

The required precision is dictated entirely by the ball's function. A ball used as a simple filler has vastly different requirements than one used as a sealing component in a high-pressure valve.

For Check Valves and Pumps

In a sealing application, both diameter and sphericity are critical. A ball with poor sphericity will not seat correctly, creating an imperfect seal and allowing leakage. An incorrect diameter can prevent the valve from closing properly or cause it to stick.

For Light-Load Bearings

For any bearing application, sphericity (low TIR) is the most important factor. An out-of-round ball will not roll smoothly, introducing vibration, noise, and premature wear into the system. The diameter tolerance is slightly less critical but still important for a proper fit.

For Volume Displacement

When PTFE balls are used simply to take up space in a chemical bath, dimensional precision is not a primary concern. In this case, a standard grade with a ±5% tolerance is perfectly suitable and significantly more cost-effective.

Understanding the Trade-offs

Choosing the right tolerance is a balance between performance requirements and budget.

Precision vs. Cost

There is a direct and often exponential relationship between tighter tolerances and higher costs. The manufacturing processes required to produce a high-precision, low-TIR ball are more complex and time-consuming.

Always ask if the application truly requires the tightest possible tolerance. Over-specifying is a common and expensive engineering mistake.

Material Properties of PTFE

PTFE is a relatively soft polymer. While this contributes to its excellent sealing properties, it also makes achieving the ultra-high precision found in ceramic or metal balls more challenging and costly. Its thermal expansion properties can also influence its dimensional stability.

Making the Right Choice for Your Goal

To select the appropriate tolerance, define the primary function of the ball in your design.

- If your primary focus is Sealing (Valves, Pumps): Specify a precision grade with a tight diameter tolerance and a low TIR (e.g., 0.003" max) to ensure a reliable seal.

- If your primary focus is Smooth Motion (Bearings): Prioritize sphericity by specifying the lowest practical TIR value, as this is critical for low-friction performance.

- If your primary focus is Cost-Effectiveness (Volume Fillers): Choose a standard grade with a wider tolerance (such as ±5%) to meet the functional need without unnecessary expense.

By matching the tolerance to the true need of your application, you ensure both reliable performance and efficient design.

Summary Table:

| Application | Diameter Tolerance | Sphericity (TIR) | Key Focus |

|---|---|---|---|

| Precision (Valves, Pumps) | +/- 0.003" to +/- 0.005" | 0.003" to 0.005" max | Sealing Reliability |

| Smooth Motion (Bearings) | Standard Precision | < 0.005" max (Lower is better) | Low Friction, Smooth Rolling |

| Cost-Effective (Volume Fillers) | ±5% (Standard Grade) | Less Critical | Functionality & Cost |

Need PTFE Balls with the Right Tolerances for Your Application?

At KINTEK, we understand that the perfect PTFE ball is defined by its precision. Whether you're designing a critical sealing component for a semiconductor valve, a low-friction bearing for medical equipment, or a cost-effective solution for a laboratory setting, we deliver the exact dimensional and form accuracy your project demands.

We specialize in custom manufacturing PTFE components—from prototypes to high-volume orders—ensuring every seal, liner, or ball meets your stringent specifications without over-engineering costs.

Let's discuss your project requirements. Contact our experts today for a consultation and quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability