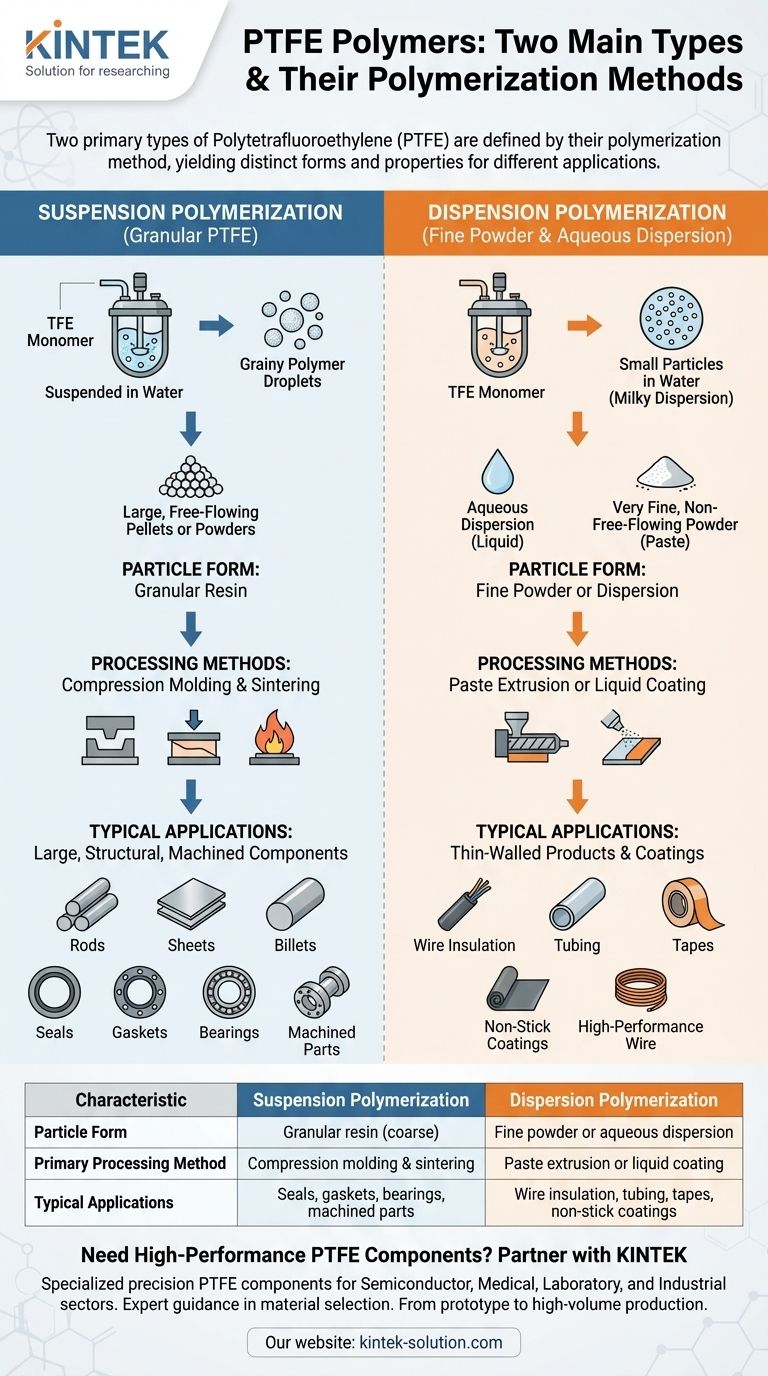

The two primary types of Polytetrafluoroethylene (PTFE) are defined by their polymerization method: suspension polymerization and dispersion polymerization. These two distinct manufacturing routes produce high molecular weight PTFE, but they yield materials with fundamentally different physical forms and processing characteristics, making each suitable for very different applications. Suspension polymerization creates granular PTFE resins for molding, while dispersion polymerization creates fine powders or aqueous dispersions for coatings and extrusion.

The core distinction between the two main types of PTFE lies in the manufacturing process. This initial step dictates the polymer's particle size and form, which in turn determines how it can be processed and what it can ultimately be used for.

The Foundation: Why Polymerization Method Matters

The properties of a finished PTFE part are not determined solely by its chemical formula. The physical form of the raw polymer, a direct result of its production method, is the critical first step in the manufacturing chain.

Suspension Polymerization: For Structural Components

Suspension polymerization is a process where the Tetrafluoroethylene (TFE) monomer is polymerized while suspended as droplets in water. This method yields a "grainy" polymer.

These grains are then processed into larger, free-flowing pellets or powders. This granular form is the key characteristic of suspension-polymerized PTFE.

Because of its particle structure, this type of PTFE is ideal for compression molding. It is used to create large, solid stock shapes like rods, sheets, and billets that can then be machined into finished parts.

Dispersion Polymerization: For Coatings and Fine Profiles

Dispersion polymerization is a more complex process that results in much smaller particles, creating a milky-white aqueous dispersion.

This dispersion can be used directly for coatings or can be coagulated to produce a very fine, non-free-flowing powder often described as a paste.

The fine particle size of dispersion-based PTFE is essential for processes like paste extrusion, which is used to create thin-walled products like wire insulation, tubing, and tapes. It's also the basis for liquid coatings, such as those used in non-stick cookware.

Understanding the Key Differences

Choosing the wrong type of raw PTFE will lead to process failure. The distinction is not subtle; it is a fundamental divide based on physical form and intended processing technology.

Particle Size and Form Factor

Suspension polymerization creates large particles, resulting in granular resins. Think of it like coarse sand, designed to be poured into a mold and compressed.

Dispersion polymerization creates sub-micron particles, resulting in a fine powder. This is more like flour, designed to be mixed with a lubricant and pushed through a die.

Required Processing Methods

Granular PTFE from suspension is processed via compression molding and sintering. Raw material is packed into a mold, compressed under high pressure, and then heated (sintered) to fuse the particles into a solid block.

Fine powder PTFE from dispersion is processed via paste extrusion or used in liquid coatings. The powder is blended with a lubricant to form a paste, which is then extruded under pressure to form a continuous profile.

Final Application and Properties

The robust, solid forms made from suspension-polymerized PTFE are suited for industrial applications requiring high strength and machinability, such as seals, gaskets, and bearings.

The thin, precise forms made from dispersion-polymerized PTFE are suited for applications requiring dielectric strength, chemical barriers, or low-friction surfaces, such as high-performance wire insulation and non-stick coatings.

Making the Right Choice for Your Application

Selecting the correct PTFE grade begins with understanding your end-use and the manufacturing process required to achieve it.

- If your primary focus is creating large, structural, or machined components (like sheets, rods, or valve seats): You must start with a granular resin produced via suspension polymerization.

- If your primary focus is producing thin-walled tubing, wire insulation, or surface coatings: You must use a fine powder or aqueous dispersion produced via dispersion polymerization.

Ultimately, the polymerization method is the single most important factor that dictates the journey of the PTFE polymer from raw material to finished product.

Summary Table:

| Characteristic | Suspension Polymerization | Dispersion Polymerization |

|---|---|---|

| Particle Form | Granular resin (coarse) | Fine powder or aqueous dispersion |

| Primary Processing Method | Compression molding & sintering | Paste extrusion or liquid coating |

| Typical Applications | Seals, gaskets, bearings, machined parts | Wire insulation, tubing, tapes, non-stick coatings |

Need High-Performance PTFE Components? Partner with KINTEK

Choosing the right PTFE type is critical for your component's performance. KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We understand the distinct properties of both suspension and dispersion PTFE polymers and can guide you in selecting the optimal material for your specific application.

Our expertise ensures your parts meet exact specifications, from prototype development to high-volume production. Let us help you achieve superior chemical resistance, thermal stability, and low friction in your products.

Contact KINTEK today to discuss your PTFE component needs and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- How was PTFE discovered? The Accidental Invention of a Super-Material

- What is the temperature resistance range of PTFE? Mastering Extreme Heat and Cold for Demanding Applications

- Is Teflon biodegradable and what are its environmental impacts? Understanding the 'Forever Material'

- What are the three ingredients used to synthesize TFE, and under what conditions are they combined? Master the High-Temp Pyrolysis Process

- What oil and gas industry uses does Teflon have? Critical Applications for Harsh Environments

- Why is PTFE considered water-resistant? The Science Behind Its Superior Barrier Properties

- What is the volume resistivity of PTFE and why is it significant? Unlock Superior Electrical Insulation

- What is the coefficient of friction of PTFE? Unlocking Its Slippery Secrets for Your Designs