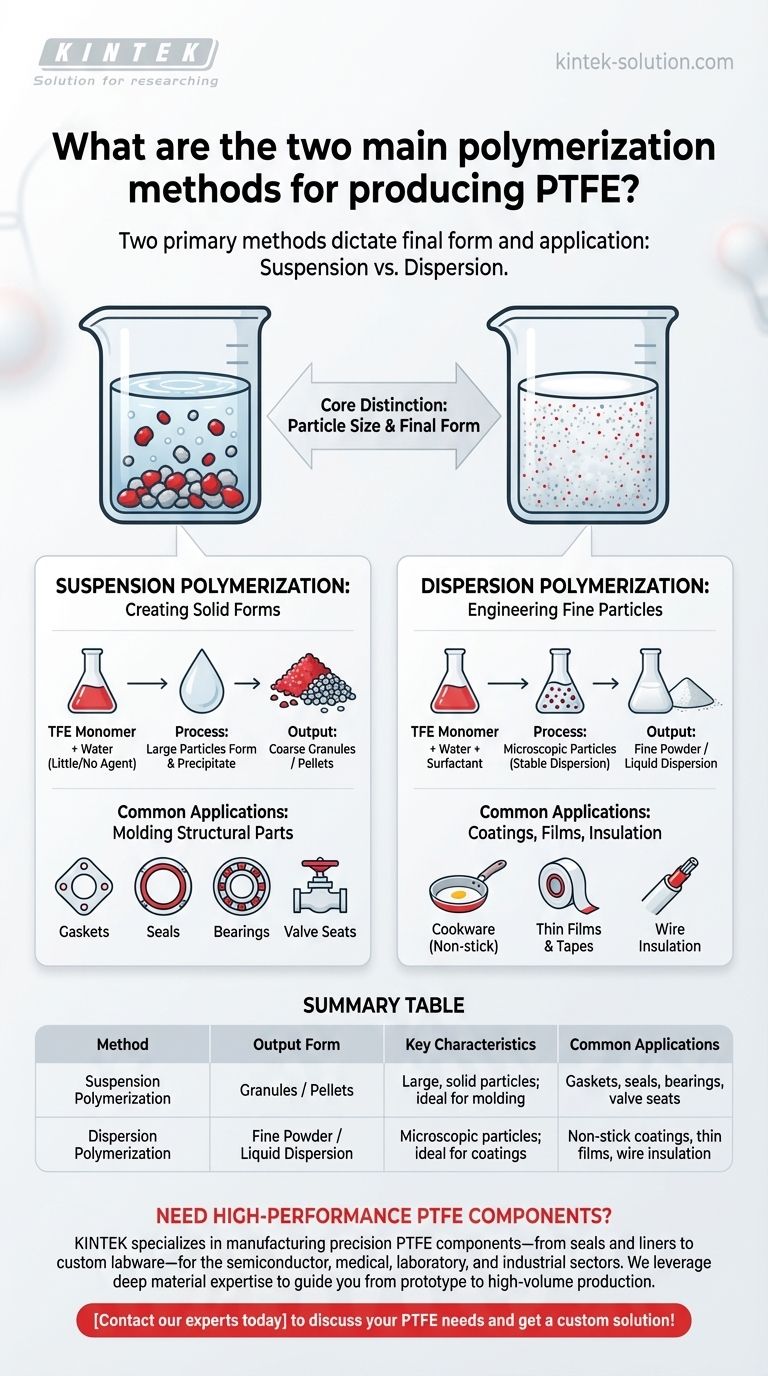

The two primary methods for producing Polytetrafluoroethylene (PTFE) are suspension polymerization and dispersion polymerization. The choice between these methods is not arbitrary; it fundamentally dictates the physical form of the resulting polymer and, consequently, its ideal applications. One method creates solid granules for molding, while the other creates fine particles for coatings.

The core distinction between the two PTFE production methods lies in the final physical form. Suspension polymerization yields large, solid grains suited for molding structural parts, while dispersion polymerization produces fine, microscopic particles ideal for creating thin coatings and films.

Suspension Polymerization: Creating Solid Forms

Suspension polymerization is designed to produce PTFE in a granular form, which serves as the raw material for solid, molded components.

The Process

In this method, the tetrafluoroethylene (TFE) monomer is polymerized while suspended as droplets in a highly purified water-based medium. The process uses little to no dispersing agent.

As the reaction proceeds, solid particles of PTFE form and precipitate out of the water.

The Output

The result is a collection of coarse, irregularly shaped PTFE grains. These grains are then typically dried and processed into free-flowing pellets or larger pre-formed shapes like billets and rods.

Common Applications

This granular or pelletized form is the feedstock for compression molding and ram extrusion. It is used to manufacture thick, durable products such as gaskets, seals, bearings, valve seats, and other structural or mechanical parts.

Dispersion Polymerization: Engineering Fine Particles

Dispersion polymerization is a more complex process engineered to create extremely small PTFE particles that can be applied as a coating or processed into thin materials.

The Process

Like the suspension method, this process also takes place in water. However, it uses a dispersing agent (surfactant) to keep the newly formed, microscopic PTFE particles from clumping together.

This results in a stable, milky-white liquid dispersion.

The Output

The direct output is a liquid dispersion containing about 20-25% fine PTFE particles by weight. This paste can be used directly for coating applications or dried through a careful process to create a very fine, non-free-flowing powder.

Common Applications

The unique properties of dispersion PTFE make it ideal for coatings, such as the non-stick layers on cookware. It is also used to create thin films, tapes (like thread seal tape), and for insulating fine wires and cables through a process called paste extrusion.

Understanding the Key Differences

The choice of polymerization method directly impacts how the resulting PTFE can be fabricated and used. The fundamental difference is a matter of particle size and intended processing.

Particle Size and Form Factor

Suspension polymerization creates large particles (grains) measured in millimeters, which are easy to handle for bulk molding processes.

Dispersion polymerization creates microscopic, sub-micron particles. This incredibly small size is what allows them to form smooth, continuous films and coatings.

Intended Fabrication Method

Granular PTFE from the suspension method is designed to be compacted under high pressure and heat (sintered) to form a solid block.

Fine powder or liquid dispersion PTFE is designed to be spread, sprayed, or extruded into very thin layers. Applying high-pressure molding to this form would not yield a quality component.

Choosing the Right PTFE for Your Application

Selecting the correct grade of PTFE begins with understanding its manufacturing origin, as this determines its suitability for your final product.

- If your primary focus is manufacturing solid, structural components: You need granular or pelletized PTFE produced via suspension polymerization, as this is the raw material for molding and machining.

- If your primary focus is creating thin coatings, films, or wire insulation: You need PTFE from dispersion polymerization, as its fine particle nature is specifically engineered for these applications.

Ultimately, understanding the production method is the first step to ensuring you select the correct PTFE grade for your specific engineering requirement.

Summary Table:

| Method | Output Form | Key Characteristics | Common Applications |

|---|---|---|---|

| Suspension Polymerization | Granules / Pellets | Large, solid particles; ideal for molding | Gaskets, seals, bearings, valve seats |

| Dispersion Polymerization | Fine Powder / Liquid Dispersion | Microscopic particles; ideal for coatings | Non-stick coatings, thin films, wire insulation |

Need High-Performance PTFE Components?

Understanding the right PTFE form is critical for your project's success. KINTEK specializes in manufacturing precision PTFE components—from seals and liners to custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

We leverage deep material expertise to guide you from prototype to high-volume production, ensuring optimal performance for your specific application.

Contact our experts today to discuss your PTFE needs and get a custom solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems