Polytetrafluoroethylene (PTFE) is produced using two primary polymerization methods. These are suspension polymerization, which creates granular PTFE resins ideal for molding into solid shapes, and dispersion polymerization, which yields a fine powder or paste used for coatings and thin films. The selection of a method is determined by the desired physical form and end-use application of the final material.

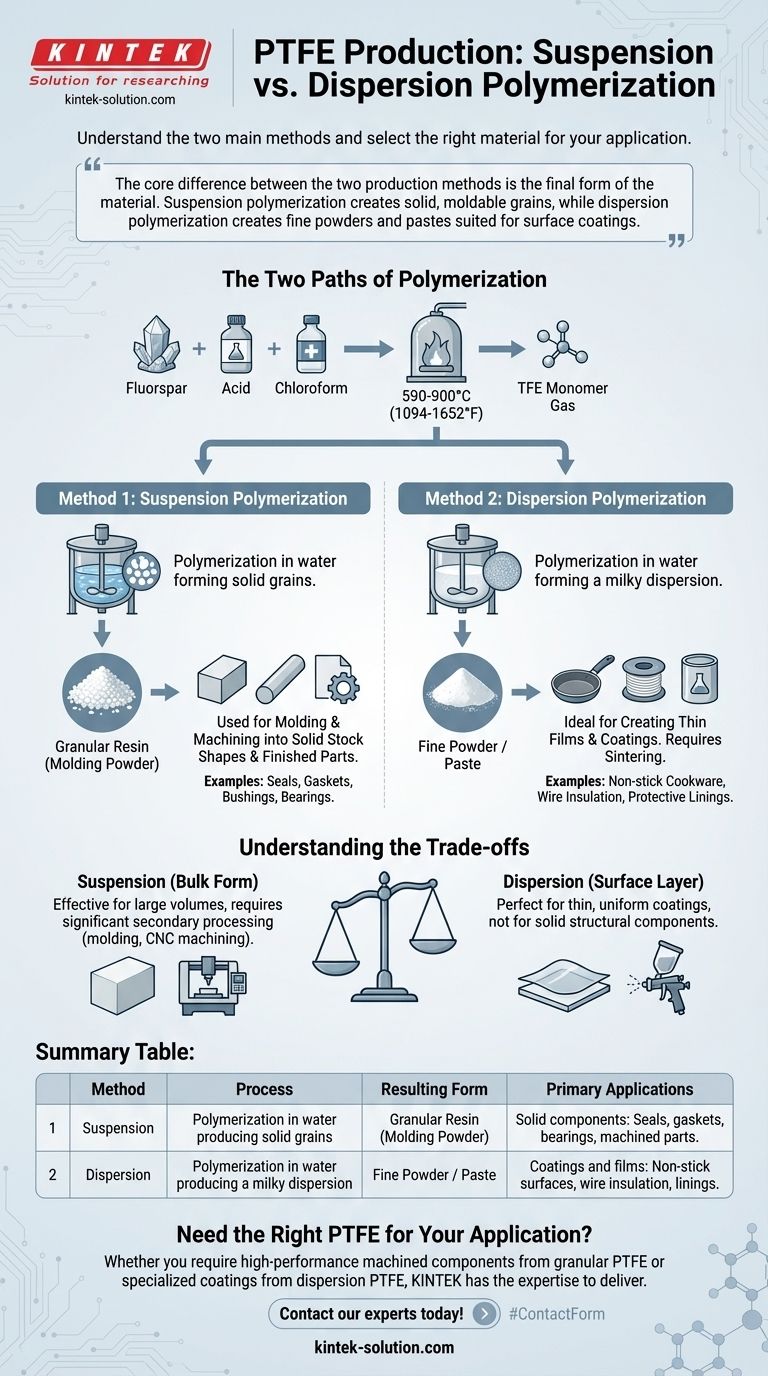

The core difference between the two production methods is the final form of the material. Suspension polymerization creates solid, moldable grains, while dispersion polymerization creates fine powders and pastes suited for surface coatings.

The Two Paths of Polymerization

Before polymerization can occur, the base monomer, tetrafluoroethylene (TFE), must be created. This involves a chemical reaction between ingredients like fluorspar, hydrofluoric acid, and chloroform at extremely high temperatures, typically between 590-900°C (1094-1652°F). Once the TFE gas is formed, it is polymerized into PTFE using one of two distinct industrial processes.

Method 1: Suspension Polymerization

Suspension polymerization involves polymerizing the TFE monomer in water. This process results in the formation of small, irregular grains of PTFE.

These grains are often called granular resin or molding powder. This is the raw material used to create solid stock shapes.

The grains can be further processed through methods like compression molding or ram extrusion to form large blocks, rods, and sheets. These solid forms are then machined into finished parts.

Method 2: Dispersion Polymerization

Dispersion polymerization also occurs in water but produces a much different result: a milky, aqueous dispersion containing tiny PTFE particles.

This dispersion can be concentrated into a paste or dried to create a fine powder. This form is not suitable for creating large, solid blocks.

Instead, the paste and fine powder are ideal for creating thin films and coatings. This is the type of PTFE used for non-stick cookware, wire insulation, and protective chemical linings.

How Production Method Dictates Application

The physical output of each polymerization method directly corresponds to a set of applications. One is not inherently superior; they are engineered for different purposes.

Granular PTFE for Solid Components

PTFE produced via suspension polymerization is the source for virtually all solid PTFE components.

The resulting granular resin is molded into stock shapes that are then machined into finished products like seals, gaskets, bushings, and high-performance bearings.

Fine Powder and Paste for Coatings

PTFE produced via dispersion polymerization is the foundation for most PTFE coatings.

Its fine particle size allows it to be applied evenly as a liquid or paste to a substrate, which is then heated (sintered) to form a durable, non-stick surface.

Understanding the Trade-offs

The choice between methods is not a matter of quality but of intended function. The primary "trade-off" is between creating bulk material for structural parts versus creating fine material for surface layers.

Bulk Form vs. Secondary Machining

Suspension polymerization is highly effective for producing large volumes of raw PTFE. The trade-off is that this bulk material almost always requires significant secondary processing, such as molding and CNC machining, to create a usable part.

Application Specificity vs. Structural Use

Dispersion polymerization produces a material perfectly suited for thin, uniform coatings. However, this form cannot be used to create solid, self-supporting structural components. The process is specialized for surface applications only.

Making the Right Choice for Your Goal

When sourcing PTFE, understanding its origin helps ensure you get the right material for the job.

- If your primary focus is creating solid, structural components: You need granular PTFE derived from suspension polymerization, which produces the resin for molding and machining.

- If your primary focus is applying a thin, non-stick, or protective layer: You need fine powder or paste PTFE derived from dispersion polymerization, which is engineered for coatings.

Ultimately, understanding the production method is the key to selecting the correct form of PTFE for your specific engineering challenge.

Summary Table:

| Method | Process | Resulting Form | Primary Applications |

|---|---|---|---|

| Suspension Polymerization | Polymerization in water producing solid grains | Granular Resin (Molding Powder) | Solid components: Seals, gaskets, bearings, machined parts |

| Dispersion Polymerization | Polymerization in water producing a milky dispersion | Fine Powder / Paste | Coatings and films: Non-stick surfaces, wire insulation, linings |

Need the Right PTFE for Your Application?

Whether you require high-performance machined components from granular PTFE or specialized coatings from dispersion PTFE, KINTEK has the expertise to deliver.

We manufacture precision PTFE components (seals, liners, labware, and more) for the semiconductor, medical, laboratory, and industrial sectors. Our custom fabrication services cover everything from prototypes to high-volume orders, ensuring you get the exact material and form for your project's success.

Let's discuss your PTFE needs – Contact our experts today!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs