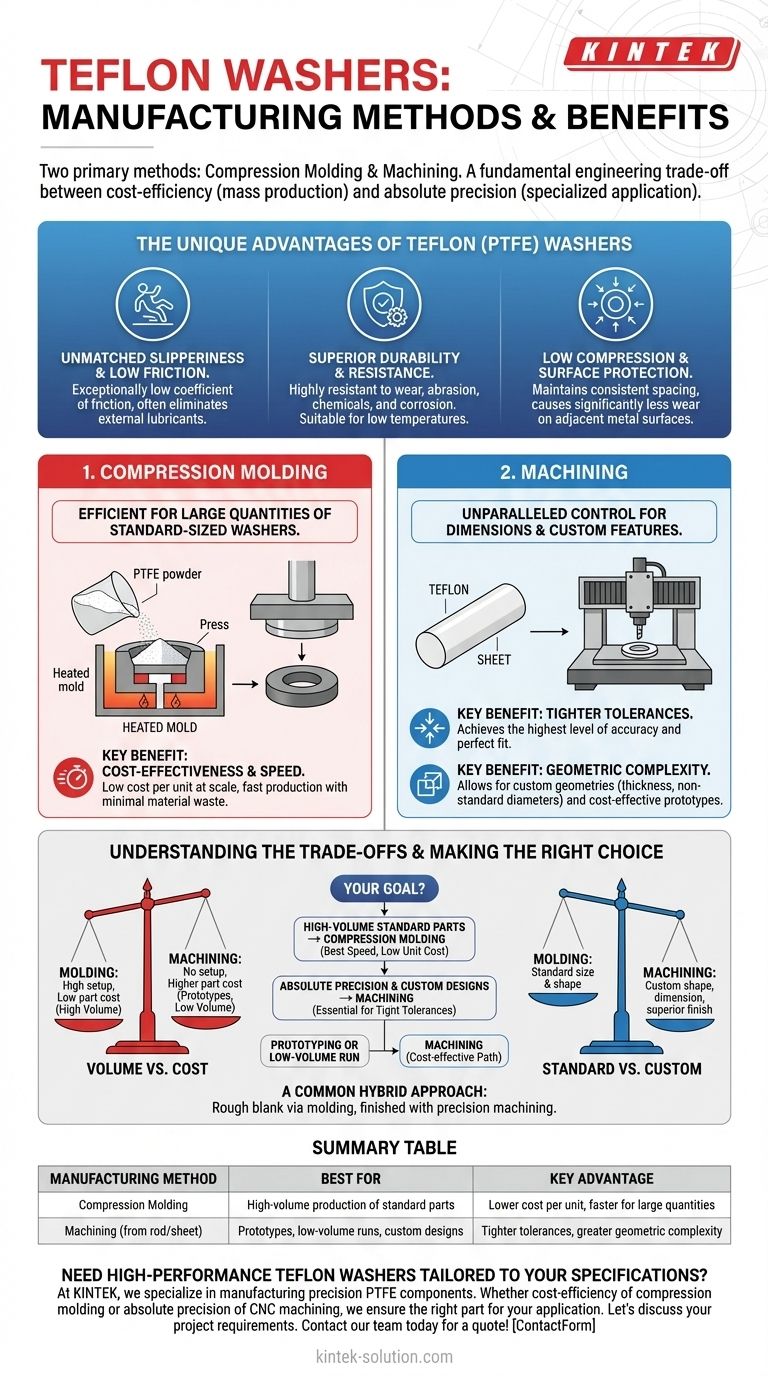

The two primary manufacturing methods for Teflon washers are compression molding and machining. Compression molding is generally faster and more cost-effective for large quantities, while machining is used to achieve tighter tolerances and more complex, custom designs.

The choice between molding and machining is a fundamental engineering trade-off. Your decision hinges on whether your project prioritizes the cost-efficiency of mass production or the absolute precision required for a specialized application.

The Unique Advantages of Teflon (PTFE) Washers

Before comparing manufacturing methods, it's essential to understand why Teflon, or Polytetrafluoroethylene (PTFE), is such a sought-after material for washers in the first place. Its distinct properties solve several key mechanical challenges.

Unmatched Slipperiness and Low Friction

Teflon is famous for being incredibly slippery. It has an exceptionally low coefficient of friction, which means parts can move against it with very little resistance.

This natural slipperiness often eliminates the need for external lubricants, making Teflon washers ideal for field use or in environments where maintenance is difficult.

Superior Durability and Resistance

Teflon is highly resistant to wear and abrasion, ensuring a long service life even in demanding conditions.

It also provides excellent chemical and corrosion resistance, performing reliably in harsh environments. Furthermore, it is a suitable material for low-temperature applications where other materials might become brittle.

Low Compression and Surface Protection

Unlike softer materials, Teflon washers are not easily compressed. This makes them ideal for maintaining consistent spacing and pressure between components, such as the blade and handle of a folding knife.

Because they are softer than metal, they also cause significantly less wear on adjacent metal surfaces compared to materials like phosphor bronze washers.

Manufacturing Method 1: Compression Molding

Compression molding is a highly efficient process for producing large quantities of standard-sized washers. It is often the default choice for high-volume manufacturing.

The Process Explained

In compression molding, a pre-measured amount of PTFE powder is placed into a heated mold cavity. A press then applies immense pressure, compacting the powder into a solid, dense washer shape.

Key Benefit: Cost-Effectiveness and Speed

The primary advantage of molding is its efficiency at scale. Once the initial mold is created, the process can produce thousands of washers quickly and with minimal material waste, driving down the cost per unit.

This makes it the most economical choice for standard parts in mass production.

Manufacturing Method 2: Machining

Machining involves cutting washers from a solid stock of Teflon, such as a rod or sheet. This method offers unparalleled control over the final product's dimensions and features.

The Process Explained

Using tools like lathes or CNC (Computer Numerical Control) machines, a skilled operator cuts, drills, and finishes the Teflon stock to precise specifications.

Key Benefit: Tighter Tolerances

Machining is the superior method for achieving extremely tight tolerances. When an application demands the highest level of accuracy and a perfect fit, machining is the only way to guarantee those results.

Key Benefit: Geometric Complexity

This method allows for the creation of custom geometries that are impossible to achieve with a standard mold. This includes unique thicknesses, non-standard diameters, or other complex features.

Machining is also highly cost-effective for low-volume and prototype runs, as it avoids the significant upfront investment required to create a custom mold.

Understanding the Trade-offs: Molding vs. Machining

Choosing the right method requires a clear understanding of your project's specific needs for volume, precision, and budget.

Volume vs. Cost

Molding has a high initial setup cost (for the mold) but a very low cost per part, making it ideal for high-volume production.

Machining has virtually no setup cost but a higher cost per part due to labor and machine time. This makes it perfect for prototypes and small production runs.

Standard vs. Custom Design

If your design uses a standard washer size and shape, molding is the most efficient option.

If you require a custom shape, a non-standard dimension, or a superior surface finish, machining is the necessary choice.

A Common Hybrid Approach

In some cases, the methods are combined. A manufacturer might create a rough "blank" via compression molding and then use machining to achieve the final, precise tolerances. This offers a balance between the speed of molding and the precision of machining.

Making the Right Choice for Your Application

Ultimately, the best manufacturing process is the one that aligns with your specific goals.

- If your primary focus is high-volume production of standard parts: Compression molding offers the best combination of speed, low unit cost, and reliable consistency.

- If your primary focus is absolute precision and custom designs: Machining is the essential choice for achieving tight tolerances and complex geometries.

- If your primary focus is prototyping or a low-volume run: Machining provides a cost-effective path to production without the high upfront tooling costs of molding.

Selecting the correct manufacturing process ensures you fully leverage the exceptional properties of Teflon for your application's success.

Summary Table:

| Manufacturing Method | Best For | Key Advantage |

|---|---|---|

| Compression Molding | High-volume production of standard parts | Lower cost per unit, faster for large quantities |

| Machining (from rod/sheet) | Prototypes, low-volume runs, custom designs | Tighter tolerances, greater geometric complexity |

Need high-performance Teflon washers tailored to your specifications?

At KINTEK, we specialize in manufacturing precision PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Whether your project requires the cost-efficiency of compression molding for a large order or the absolute precision of CNC machining for a custom prototype, our expertise ensures you get the right part for your application.

Let's discuss your project requirements and find the optimal manufacturing solution. Contact our team today for a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does temperature affect PTFE slide bearing performance? Ensure Reliability Under High Heat

- What precautions should be taken when machining PTFE? Master the Process for Precise Components

- What material is commonly used for lining valves, and what are its properties? Discover the Power of PTFE Liners

- Which regulatory standards do PTFE rotary shaft seals comply with? Ensure Compliance for Your Application

- How are PTFE guide strips used in the chemical and pharmaceutical industries? Essential for Sealing and Purity

- What types of components are commonly manufactured from PTFE? Seals, Bearings, Insulators & More

- How are PTFE Bellows manufactured? A Guide to Precision Thermal Forming

- How does chemical resistance benefit PTFE Teflon washers? Ensure Leak-Free Seals in Harsh Environments