In industrial applications, PTFE flange gaskets deliver critical safety benefits through their unique combination of properties. They provide exceptional chemical resistance, maintain a reliable seal across extreme temperatures and pressures, and resist physical degradation over time. These characteristics work together to prevent dangerous leaks of hazardous materials, protecting personnel, equipment, and the environment.

The primary safety benefit of a PTFE gasket is not a single feature, but its systemic reliability. By resisting chemical attack, temperature extremes, and physical deformation, it prevents the single most common point of failure in a flanged connection: the loss of the seal.

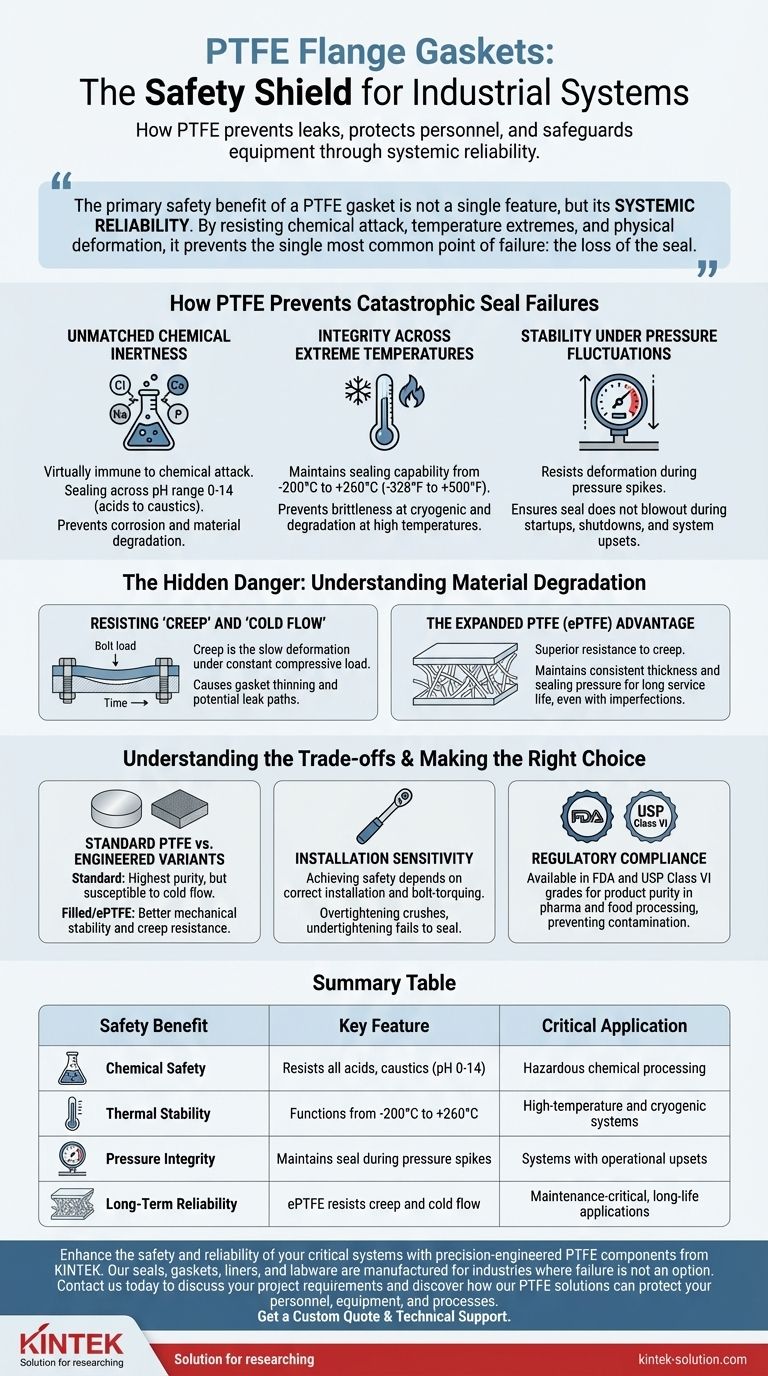

How PTFE Prevents Catastrophic Seal Failures

The safety of a flanged joint depends entirely on the gasket's ability to maintain a perfect seal under operational stress. PTFE is engineered to excel in this role through three core protective mechanisms.

Unmatched Chemical Inertness

PTFE is virtually immune to chemical attack. It can safely seal media across the entire pH range (0-14), from the most aggressive acids to the strongest caustics.

This inertness prevents the gasket from being corroded or "eaten away" by the fluid it contains. This is a leading cause of long-term seal failure with less-resistant materials, making PTFE the default choice for handling hazardous chemicals.

Integrity Across Extreme Temperatures

PTFE gaskets maintain their integrity and sealing capability over an exceptionally wide temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This prevents the material from becoming brittle at cryogenic temperatures or degrading at high temperatures. Either extreme would compromise the seal, leading to an immediate and dangerous leak.

Stability Under Pressure Fluctuations

A reliable seal must withstand the pressure variations inherent in industrial processes, such as startups, shutdowns, and system upsets.

PTFE gaskets maintain their structural form under these changing loads, ensuring the seal does not "blow out" or loosen during pressure spikes. This stability is fundamental to operational safety.

The Hidden Danger: Understanding Material Degradation

Beyond immediate failures, a key safety concern is the gradual degradation of the gasket material over time. This can lead to slow, often undetected leaks that pose a significant long-term risk.

Resisting "Creep" and "Cold Flow"

Creep, or cold flow, is the tendency of a material to slowly deform under a constant compressive load, such as the pressure from flange bolts. Over time, this causes the gasket to thin, reducing the sealing force and creating a potential leak path.

While standard PTFE can be susceptible to this, a specialized variant—expanded PTFE—is engineered to solve this problem.

The Expanded PTFE (ePTFE) Advantage

Expanded PTFE (ePTFE) has a unique fibrous structure that gives it superior resistance to creep. It maintains a more consistent thickness and sealing pressure for a much longer service life.

This makes ePTFE a significantly safer choice for applications with high pressure, temperature cycling, or where long-term, maintenance-free reliability is paramount.

Adapting to Imperfect Surfaces

Real-world flange surfaces are rarely perfectly flat; they can be warped, scratched, or corroded. A rigid gasket may fail to seal these imperfections.

Expanded PTFE's soft, conformable nature allows it to flow into and seal these small irregularities. This adaptability ensures a reliable seal even on older or slightly damaged flanges, extending the service life and safety of the connection.

Understanding the Trade-offs

While highly effective, no material is perfect for every situation. Objectivity requires acknowledging PTFE's limitations to ensure proper application.

Standard PTFE vs. Engineered Variants

Standard, unfilled PTFE offers the highest chemical purity but is the most susceptible to cold flow. For demanding applications, filled PTFE (with materials like glass or silica) or expanded PTFE provide better mechanical stability and creep resistance.

Installation Sensitivity

PTFE is a relatively soft material. Achieving its safety benefits is critically dependent on following correct installation and bolt-torquing procedures. Overtightening can crush the gasket, while under-tightening will fail to create an effective seal.

Regulatory Compliance

In industries like pharmaceuticals or food processing, safety extends to product purity. PTFE gaskets are available in grades that meet strict FDA and USP Class VI standards, ensuring they are non-toxic and will not contaminate the process media.

Making the Right Choice for Your Application

Selecting the correct gasket is an engineering decision that directly impacts system safety. Use the specific demands of your service to guide your choice.

- If your primary focus is aggressive chemical service: PTFE's near-total chemical inertness across the full pH range makes it the safest and most reliable choice to prevent corrosion-based failures.

- If your primary focus is long-term reliability under pressure or thermal cycling: Expanded PTFE (ePTFE) is the superior option, as its resistance to creep ensures the seal remains tight and secure over time.

- If your primary focus is product purity for food or pharma: Specify a PTFE gasket that meets FDA or USP Class VI standards to guarantee biocompatibility and prevent process contamination.

Ultimately, selecting the correct type of PTFE gasket is a critical decision that directly enhances the safety and integrity of your entire system.

Summary Table:

| Safety Benefit | Key Feature | Critical Application |

|---|---|---|

| Chemical Safety | Resists all acids, caustics (pH 0-14) | Hazardous chemical processing |

| Thermal Stability | Functions from -200°C to +260°C | High-temperature and cryogenic systems |

| Pressure Integrity | Maintains seal during pressure spikes | Systems with operational upsets |

| Long-Term Reliability | ePTFE resists creep and cold flow | Maintenance-critical, long-life applications |

Enhance the safety and reliability of your critical systems with precision-engineered PTFE components from KINTEK.

Our PTFE seals, gaskets, liners, and labware are manufactured to the highest standards for industries where failure is not an option—semiconductor, medical, pharmaceutical, laboratory, and industrial processing. We provide custom fabrication from prototypes to high-volume production, ensuring a perfect fit and unmatched performance for your specific application.

Contact us today to discuss your project requirements and discover how our PTFE solutions can protect your personnel, equipment, and processes. Get a Custom Quote & Technical Support

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability