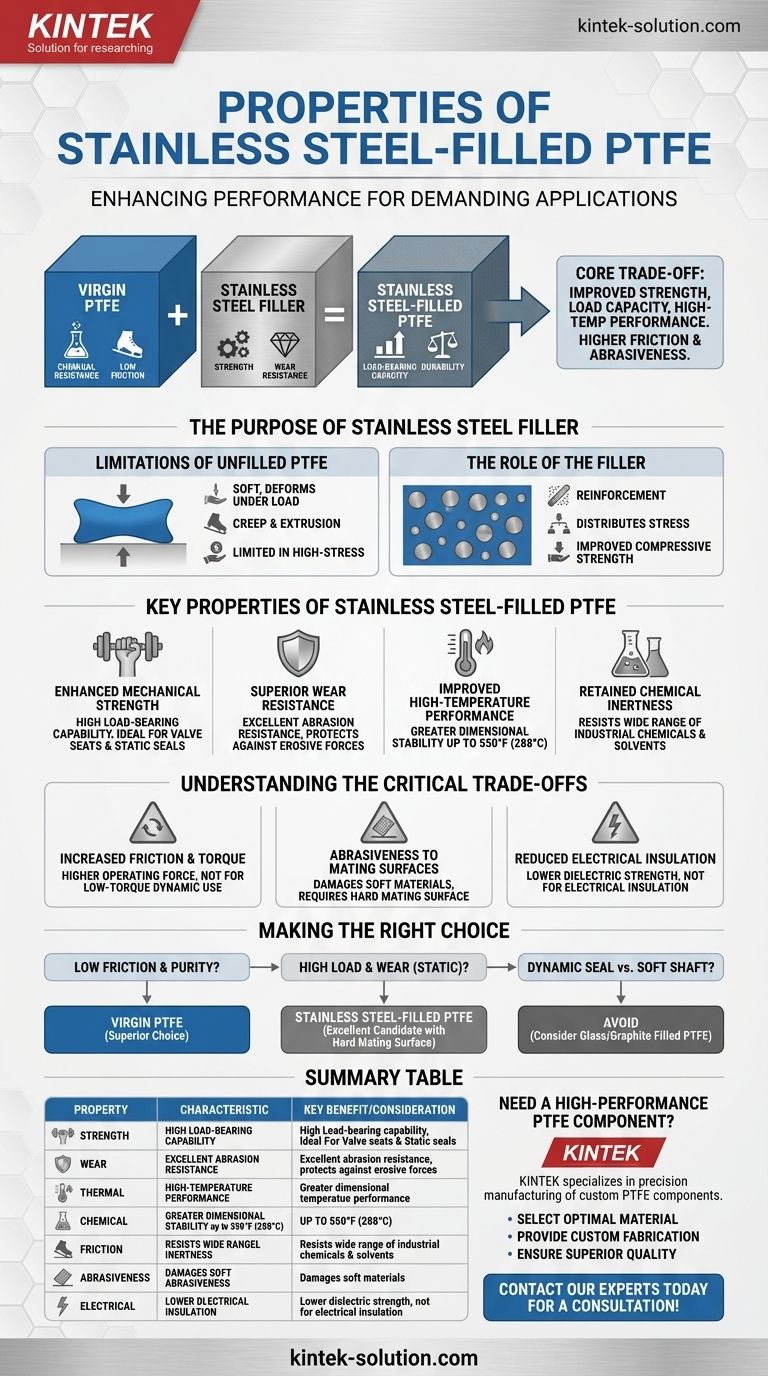

In essence, stainless steel-filled PTFE is a composite material engineered to enhance the mechanical properties of virgin PTFE. It combines the chemical resistance and low-friction nature of PTFE with the strength and wear resistance of stainless steel, creating a material suited for demanding static applications under high loads.

The core trade-off is simple: adding stainless steel to PTFE dramatically improves its strength, load-bearing capacity, and high-temperature performance. However, this comes at the cost of a higher coefficient of friction and significant abrasiveness to mating surfaces.

The Purpose of a Stainless Steel Filler

To understand this composite, you must first understand the limitations of the base material. While remarkable, pure PTFE has its weaknesses.

The Limitations of Unfilled PTFE

Virgin PTFE is an exceptionally slippery and chemically inert polymer. Its primary drawback is that it is mechanically soft.

Under high pressure or load, pure PTFE can deform, creep, or extrude from its housing. This limits its use in high-stress structural or sealing applications.

The Role of the Filler

Introducing powdered stainless steel particles (typically 316L) into the PTFE matrix acts as a reinforcement.

These metal particles distribute stress throughout the material, significantly improving its compressive strength and resistance to deformation under load.

Key Properties of Stainless Steel-Filled PTFE

The resulting composite material possesses a unique blend of characteristics inherited from both its parent materials.

Enhanced Mechanical Strength

The primary benefit is a substantial increase in load-bearing capability. This makes it an ideal choice for components like valve seats and static seals that must withstand high pressures without failing.

Superior Wear Resistance

The hard steel particles provide excellent wear and abrasion resistance for the component itself. This property is crucial in applications like flow control valves where the material is subject to erosive forces.

Improved High-Temperature Performance

While virgin PTFE has a wide operating temperature range, the addition of stainless steel provides greater dimensional stability at elevated temperatures. Some grades can operate at up to 550°F (288°C), slightly higher than standard PTFE.

Retained Chemical Inertness

Stainless steel-filled PTFE largely retains the outstanding chemical resistance of virgin PTFE. It remains suitable for use with a wide range of industrial chemicals and solvents, making it a valuable material in processing industries.

Understanding the Critical Trade-offs

This material is not a universal upgrade over pure PTFE. The enhancements come with significant compromises that you must consider for your application.

Increased Friction and Torque

The material is no longer the "slipperiest solid." The steel filler increases the coefficient of friction. In dynamic applications like a valve stem seal, this translates directly to higher required torque to operate the valve.

Abrasiveness to Mating Surfaces

This is the most critical drawback. The hard stainless steel particles that provide wear resistance for the PTFE part will abrade softer mating surfaces. Using this material against a soft metal or plastic component will cause rapid wear on the adjacent part.

Reduced Electrical Insulation

Pure PTFE is an exceptional electrical insulator. Introducing conductive metal particles into the matrix compromises its dielectric strength, making it unsuitable for applications requiring high levels of electrical insulation.

Making the Right Choice for Your Application

Selecting the correct material requires a clear understanding of your primary design goal.

- If your primary focus is lowest possible friction and chemical purity: Virgin PTFE is the superior choice.

- If your primary focus is high load and wear resistance in a static seal: Stainless steel-filled PTFE is an excellent candidate, provided the mating surface is sufficiently hard.

- If your primary focus is a dynamic seal against a soft shaft: Avoid this material. Its abrasiveness will likely damage the shaft. Consider a PTFE composite with a softer filler, such as glass or graphite.

Ultimately, choosing the right material means balancing the specific enhancements you need against the inherent properties you are willing to sacrifice.

Summary Table:

| Property | Characteristic | Key Benefit / Consideration |

|---|---|---|

| Mechanical Strength | High Compressive Strength | Excellent for high-load static applications (e.g., valve seats). |

| Wear Resistance | Excellent Abrasion Resistance | Ideal for components subject to erosive forces. |

| Thermal Performance | Enhanced Dimensional Stability (up to 550°F / 288°C) | Suitable for high-temperature environments. |

| Chemical Resistance | Retains PTFE's Inertness | Resists a wide range of industrial chemicals and solvents. |

| Friction | Higher Coefficient of Friction | Not ideal for low-torque dynamic applications; can increase operating force. |

| Abrasiveness | Abrasive to Mating Surfaces | Can damage softer adjacent components; requires a hard mating surface. |

| Electrical Properties | Reduced Dielectric Strength | Not suitable for electrical insulation applications. |

Need a High-Performance PTFE Component for Your Application?

Choosing the right material is critical for the performance and longevity of your components. The unique properties of stainless steel-filled PTFE make it an excellent solution for demanding applications in the semiconductor, medical, laboratory, and industrial sectors where high load-bearing capacity and wear resistance are paramount.

KINTEK specializes in the precision manufacturing of PTFE components, including custom stainless steel-filled formulations. We work with you to:

- Select the optimal material based on your specific load, temperature, and chemical exposure requirements.

- Provide custom fabrication from prototypes to high-volume production runs.

- Ensure superior quality with components that deliver reliability under the most challenging conditions.

Let's engineer the perfect solution for your needs. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability