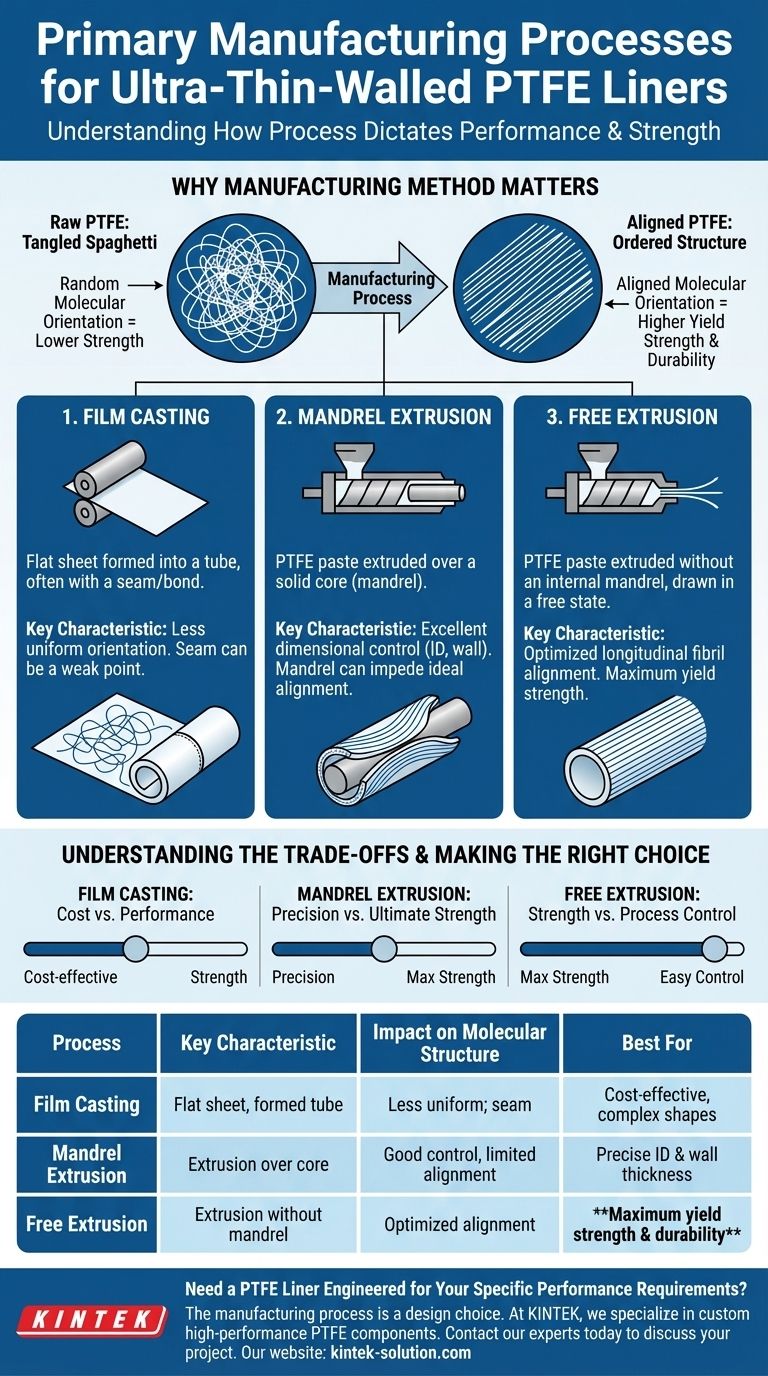

The primary manufacturing processes for ultra-thin-walled PTFE liners are film casting, free extrusion, and mandrel extrusion. These methods are not interchangeable; the choice of process directly dictates the liner's internal molecular structure, which in turn determines its mechanical performance, particularly its strength.

The most critical takeaway is that the manufacturing method is not merely a production detail—it is a design choice. The process fundamentally alters the PTFE's molecular alignment, with free extrusion generally producing the strongest liners by optimizing this internal structure.

Why the Manufacturing Method Matters

Before examining the processes, it's essential to understand why the method is so critical. PTFE's exceptional properties, like its extremely low friction and chemical inertness, are inherent to the material. However, its mechanical strength is heavily influenced by its manufacturing.

The Impact of Molecular Orientation

The key factor is fibril molecular arrangement. Think of raw PTFE as a container of tangled spaghetti strands (polymer chains). A well-designed manufacturing process attempts to untangle and align these strands in a specific direction.

When the polymer chains are aligned, the material exhibits significantly higher yield strength and durability. This orientation is the primary differentiator between a standard liner and a high-performance one.

A Breakdown of the Core Processes

Each of the three main processes organizes these molecular "strands" differently, resulting in distinct performance characteristics.

Film Casting

Film casting typically involves creating a thin, flat sheet of PTFE which is then rolled or formed into a tubular shape. This process may involve a seam or a thermal bond.

While versatile, this method often results in less uniform molecular orientation compared to extrusion. The strength can be inconsistent, particularly if a seam is present.

Mandrel Extrusion

In this process, PTFE paste is extruded over a solid core, or mandrel. The liner is formed in the space between the extrusion die and this internal mandrel.

This method offers excellent control over the liner's inner diameter and wall thickness. However, the presence of the mandrel can impede the ideal alignment of polymer fibrils, limiting the ultimate strength potential compared to free extrusion.

Free Extrusion

Free extrusion involves forcing PTFE paste through a die without the use of an internal mandrel. The liner is formed and drawn in a "free" state, allowing the polymer chains to align themselves longitudinally along the direction of the draw.

This process is specifically noted for its ability to optimize molecular orientation. The result is a seamless liner with a highly aligned fibril structure, which significantly enhances its yield strength and overall mechanical integrity.

Understanding the Trade-offs

No single process is universally superior; the optimal choice depends entirely on the application's specific requirements.

Film Casting: Cost vs. Performance

This method can be cost-effective for certain geometries but generally represents a compromise on mechanical strength and seamless integrity. It is rarely the choice for high-pressure or high-stress applications.

Mandrel Extrusion: Precision vs. Ultimate Strength

This is the go-to process when exact dimensional tolerance is the most critical factor. The trade-off is a potential reduction in maximum tensile strength compared to what can be achieved with free extrusion.

Free Extrusion: Strength vs. Process Control

This process yields the highest mechanical strength and lubricity due to superior molecular alignment. However, maintaining ultra-tight dimensional tolerances without an internal mandrel requires a higher degree of process expertise and control.

Making the Right Choice for Your Application

Selecting the correct process requires a clear understanding of your primary engineering goal.

- If your primary focus is maximum mechanical strength and durability: Free extrusion is the superior choice, as it produces the most favorable molecular orientation.

- If your primary focus is maintaining precise dimensional tolerances: Mandrel extrusion offers the best control over the liner's final geometry.

- If your primary focus is creating a complex or non-tubular shape from a thin film: Film casting offers a level of geometric versatility that extrusion cannot.

Ultimately, understanding the link between the manufacturing process and the resulting molecular structure empowers you to specify the exact liner your application demands.

Summary Table:

| Process | Key Characteristic | Impact on Molecular Structure | Best For |

|---|---|---|---|

| Film Casting | Creates a flat sheet formed into a tube | Less uniform orientation; potential seam | Cost-effective, complex shapes |

| Mandrel Extrusion | Extrusion over a solid core (mandrel) | Good dimensional control, limited fibril alignment | Precise inner diameter & wall thickness |

| Free Extrusion | Extrusion without an internal mandrel | Optimized longitudinal fibril alignment | Maximum yield strength & durability |

Need a PTFE Liner Engineered for Your Specific Performance Requirements?

The manufacturing process is a design choice that defines your liner's strength and precision. At KINTEK, we specialize in manufacturing high-performance PTFE components, including seals, liners, and labware. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures your PTFE liner is optimized for your application, whether in semiconductor, medical, laboratory, or industrial settings.

Contact our experts today to discuss your project and leverage our precision production capabilities.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the general advantages of O-ring designs? Achieve Reliable, Cost-Effective Sealing

- What is the typical bond strength of etched PTFE to metals? Achieve Reliable Sealing & Positioning

- Why are PTFE rotary seals becoming a preferred choice for engineers and OEMs? Solve Critical Performance Failures

- How does the long life and wear resistance of Teflon gland fillers reduce maintenance needs?

- Where is PTFE packing typically used? The Go-To Sealing Solution for Harsh Environments

- What maintenance practices ensure optimal performance of PTFE-lined plug valves? A Proactive Guide to Reliability

- How do PTFE and nylon differ in terms of water interactivity? Key Differences for Component Stability

- What are the advantages of PTFE sealing materials in improving ball valve performance? Boost Reliability & Lifespan