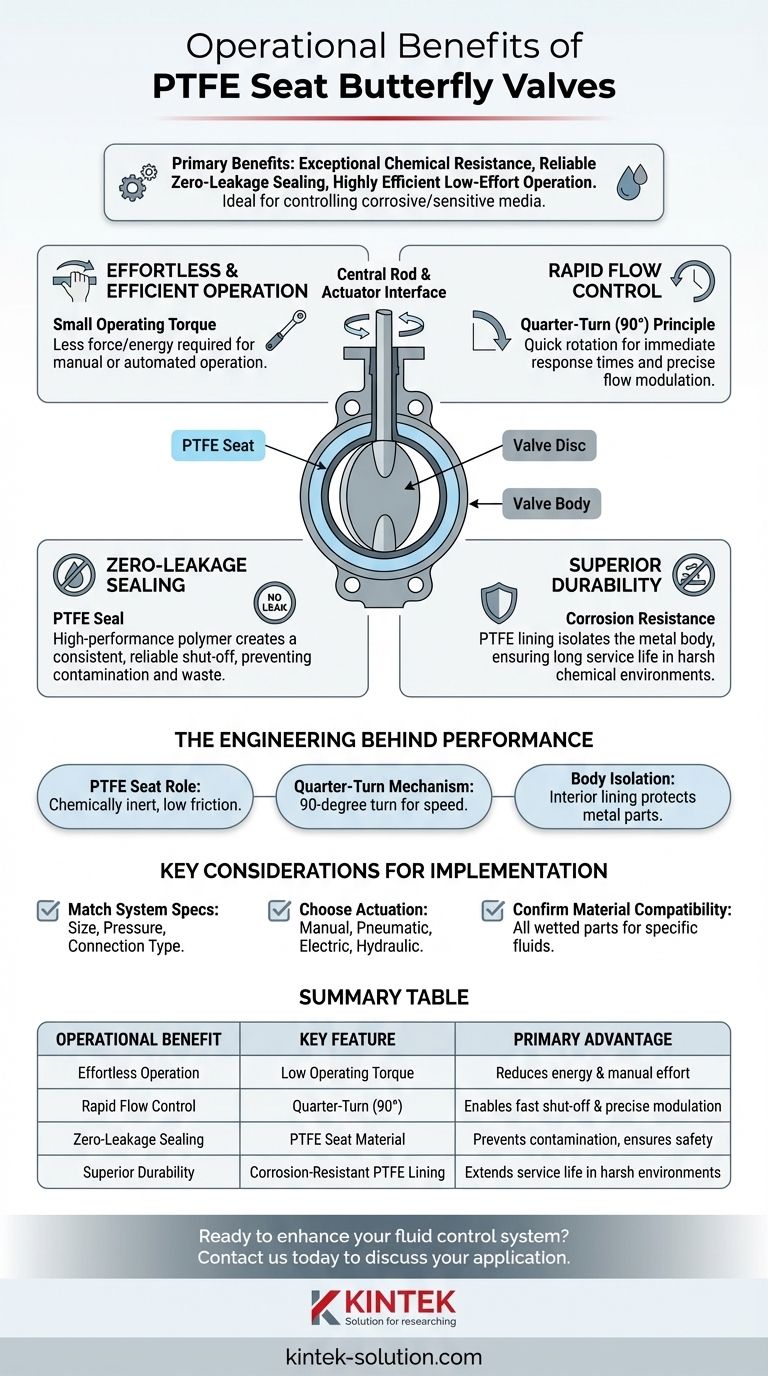

In short, the primary operational benefits of a PTFE seat butterfly valve are its exceptional chemical resistance, reliable zero-leakage sealing, and highly efficient, low-effort operation. This combination makes it a superior choice for controlling corrosive or sensitive media where both performance and durability are critical. Its simple, quarter-turn design also allows for rapid opening and closing, saving both time and energy.

The core value of a PTFE seat butterfly valve is its ability to deliver the speed and simplicity of a standard butterfly valve while adding a robust layer of chemical protection and superior sealing, making it ideal for demanding industrial applications.

Understanding the Core Operational Advantages

The operational benefits of a PTFE seat butterfly valve stem directly from its unique combination of materials and mechanical design. These features solve common challenges related to fluid control in aggressive environments.

Effortless and Efficient Operation

The design provides a small operating torque. This means less physical force or energy is required to open and close the valve.

This low-torque requirement makes manual operation easier for personnel and reduces the energy consumption of automated pneumatic or electric actuators.

Rapid Flow Control

Like all butterfly valves, it operates on a quarter-turn (90-degree) principle. The disc moves from fully closed to fully open with a simple, quick rotation.

This allows for rapid shut-off and precise flow modulation, which is essential in processes requiring immediate response times.

Zero-Leakage Sealing

The Polytetrafluoroethylene (PTFE) seat provides an excellent and reliable seal. This high-performance polymer creates a tight shut-off against the valve disc.

This consistent sealing performance minimizes waste, prevents contamination, and enhances system safety, achieving what is often referred to as zero leakage.

Superior Durability in Harsh Environments

The key feature is its corrosion resistance. The PTFE lining effectively isolates the valve's metal body from the fluid medium.

This means the valve can handle highly corrosive or abrasive media for extended periods without degrading, ensuring a long service life and reducing maintenance costs.

The Engineering Behind the Performance

The benefits aren't accidental; they are the result of specific design choices that leverage the properties of both the valve type and the seating material.

The Role of the PTFE Seat

PTFE is a fluoropolymer known for being chemically inert and having a very low coefficient of friction. This is what provides the corrosion resistance and contributes to the low operating torque.

The Quarter-Turn Mechanism

The valve’s disc, or "butterfly," is mounted on a central rod. A 90-degree turn of this rod, via a handwheel or actuator, is all that is needed to move the valve between its open and closed states, ensuring its characteristic speed.

Isolation of the Valve Body

By lining the interior, the PTFE seat ensures that the fluid only comes into contact with the PTFE material and the disc. The main valve body, typically made of metal, is completely protected from the potentially corrosive effects of the process fluid.

Key Considerations for Implementation

While operationally excellent, selecting the right valve requires careful evaluation of your specific system to realize these benefits fully. Mistaking these details can undermine the valve's performance.

Matching the Valve to Your System

The valve's size, pressure rating, and connection type (wafer, lug, or flanged) must precisely match the specifications of your piping system. A mismatch can lead to leaks, flow issues, or catastrophic failure.

Choosing the Right Actuation

Operation can be manual, pneumatic, electric, or hydraulic. The choice depends on the need for speed, torque requirements, and whether remote or automated control is necessary for the process.

Ensuring Full Material Compatibility

While the PTFE seat handles a vast range of chemicals, you must confirm that all wetted parts, including the disc itself, are fully compatible with the specific fluids, temperatures, and pressures in your application. This is the single most critical factor for ensuring long service life.

Planning for Automation

These valves are easily equipped with pneumatic and electric devices. This allows for seamless integration into automated systems for remote operation and programmed control, a significant benefit for modern process facilities.

Making the Right Choice for Your Application

To leverage the benefits of a PTFE seat butterfly valve, align your selection with your primary operational goal.

- If your primary focus is process speed and efficiency: The rapid, quarter-turn actuation and low energy requirement make this an ideal choice for fast-cycling applications.

- If your primary focus is handling corrosive chemicals: The PTFE lining provides a reliable and cost-effective solution for protecting system components and ensuring zero-leakage sealing.

- If your primary focus is automated or remote control: The valve's compatibility with standard electric and pneumatic actuators allows for straightforward integration into a modern control system.

Ultimately, selecting a PTFE seat butterfly valve is a strategic choice for durable, efficient, and precise control in challenging chemical environments.

Summary Table:

| Operational Benefit | Key Feature | Primary Advantage |

|---|---|---|

| Effortless Operation | Low operating torque | Reduces energy consumption and manual effort |

| Rapid Flow Control | Quarter-turn (90°) mechanism | Enables fast shut-off and precise modulation |

| Zero-Leakage Sealing | PTFE seat material | Prevents contamination and ensures system safety |

| Superior Durability | Corrosion-resistant PTFE lining | Extends service life in harsh chemical environments |

Ready to enhance your fluid control system with a durable, high-performance PTFE seat butterfly valve?

At KINTEK, we specialize in the precision manufacturing of high-quality PTFE components, including seals, liners, and custom labware. Our expertise is perfect for industries like semiconductor, medical, and laboratory, where reliable performance in corrosive or sensitive environments is non-negotiable.

We offer custom fabrication from prototypes to high-volume orders, ensuring you get a valve solution perfectly tailored to your specific pressure, temperature, and chemical compatibility requirements.

Contact us today to discuss your application and discover how our PTFE components can deliver superior sealing and long-lasting performance for your most demanding processes.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments