The defining performance characteristics of PTFE seals are their extreme chemical resistance, exceptionally wide operating temperature range, and the lowest coefficient of friction of any solid material. This unique combination allows them to operate reliably in high-pressure, high-speed, and corrosive environments where conventional elastomer seals would quickly degrade and fail.

The core value of a PTFE seal is its ability to provide a durable, low-friction seal in chemically aggressive or high-temperature environments. It solves sealing challenges that are simply beyond the physical and chemical limits of most other materials.

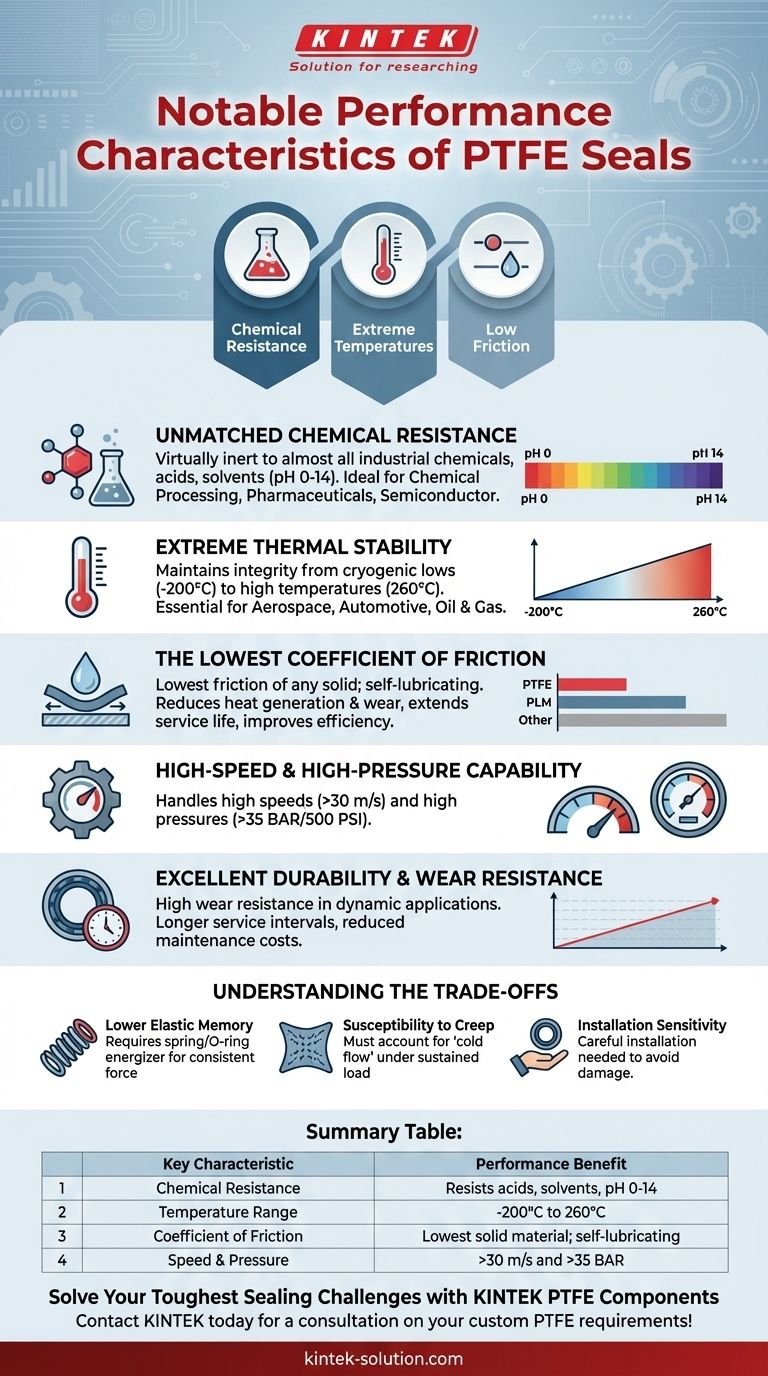

The Pillars of PTFE Seal Performance

The performance of Polytetrafluoroethylene (PTFE) seals is built on a few fundamental material properties that give them a significant advantage in demanding applications. Understanding these pillars is key to deploying them effectively.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals, acids, solvents, and corrosive fluids. It can handle substances across the entire pH range from 0 to 14.

This makes PTFE the material of choice for industries like chemical processing, pharmaceuticals, and semiconductor manufacturing, where seals are exposed to highly aggressive media.

Extreme Thermal Stability

PTFE seals maintain their integrity and sealing properties across an exceptionally broad temperature spectrum, typically from cryogenic lows of -200°C up to 260°C (-328°F to 500°F).

This thermal stability makes them indispensable in aerospace, automotive, and oil and gas applications where components must perform reliably under extreme heat or cold.

The Lowest Coefficient of Friction

PTFE has one of the lowest friction coefficients of any solid, making it naturally slick and self-lubricating.

This property is critical for performance. It reduces heat generation and wear on both the seal and the mating hardware, which dramatically extends the service life and improves the overall efficiency of the system.

High-Speed and High-Pressure Capability

The low-friction nature of PTFE allows these seals to operate at very high surface speeds, often exceeding 30 m/s (meters per second).

They are also engineered to maintain a tight seal in high-pressure systems, with some designs performing effectively above 35 BAR (500 PSI).

Excellent Durability and Wear Resistance

The combination of low friction and material strength results in high wear resistance, particularly in dynamic applications like reciprocating shafts.

This durability leads to longer service intervals and reduced maintenance costs, a significant operational advantage in industrial machinery.

Understanding the Trade-offs

While PTFE offers exceptional performance, it's a specialized material with unique behaviors. Acknowledging its limitations is crucial for proper design and application.

Lower Elastic Memory

Unlike rubber elastomers, PTFE is not highly elastic and does not "bounce back" to its original shape as effectively after being compressed. This is why many PTFE seals incorporate a spring or O-ring energizer to provide a consistent sealing force.

Susceptibility to Creep

Under a sustained compressive load, especially at elevated temperatures, PTFE can be susceptible to "creep" or "cold flow." This slow deformation must be accounted for in the gland design to ensure long-term sealing integrity.

Installation Sensitivity

The relative stiffness of PTFE compared to rubber means that seals can be more challenging to install. Care must be taken to avoid scratching or gouging the seal lip, as any damage can create a permanent leak path.

Making the Right Choice for Your Application

Selecting a PTFE seal is a decision driven by the specific demands of your operating environment.

- If your primary focus is aggressive media: PTFE's near-total chemical inertness makes it the safest and most reliable choice for sealing acids, solvents, and other corrosive fluids.

- If your primary focus is high-speed dynamics: The extremely low friction coefficient minimizes heat and wear, enabling reliable sealing in high-speed rotating or reciprocating equipment.

- If your primary focus is extreme temperatures: PTFE provides a stable sealing solution in applications ranging from cryogenic systems to high-heat engines, where elastomers would become brittle or melt.

- If your primary focus is a dry-running system: PTFE's self-lubricating properties allow it to operate effectively without external lubrication, preventing contamination in food, medical, or electronic applications.

Ultimately, PTFE seals provide robust and reliable performance by thriving in the exact conditions where most other sealing materials fail.

Summary Table:

| Key Characteristic | Performance Benefit |

|---|---|

| Chemical Resistance | Resists virtually all acids, solvents, and corrosive media (pH 0-14) |

| Temperature Range | Operates from cryogenic -200°C to high-temperature 260°C |

| Coefficient of Friction | Lowest of any solid material; self-lubricating |

| Speed & Pressure | Handles speeds >30 m/s and pressures >35 BAR |

Solve Your Toughest Sealing Challenges with KINTEK PTFE Components

Do your applications involve aggressive chemicals, extreme temperatures, or high-speed dynamics? Standard elastomer seals often fail in these demanding conditions. KINTEK specializes in manufacturing high-performance, precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We provide custom fabrication from prototypes to high-volume orders, ensuring a perfect fit for your specific needs. Our expertise in PTFE means you get a sealing solution that offers superior durability, reduced maintenance, and long-term reliability.

Let us help you enhance your system's performance and efficiency. Contact KINTEK today for a consultation on your custom PTFE requirements!

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are PTFE seals and why are they considered a reliable solution for extreme environments? Engineered for Harsh Conditions

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals

- What are the benefits of using PTFE seals in demanding industries? Solve Extreme Sealing Challenges

- What are the benefits of PTFE seals in terms of prototyping and production? Accelerate R&D and Ensure Elite Performance

- What are the five outstanding characteristics of PTFE seals? Engineered for Extreme Performance