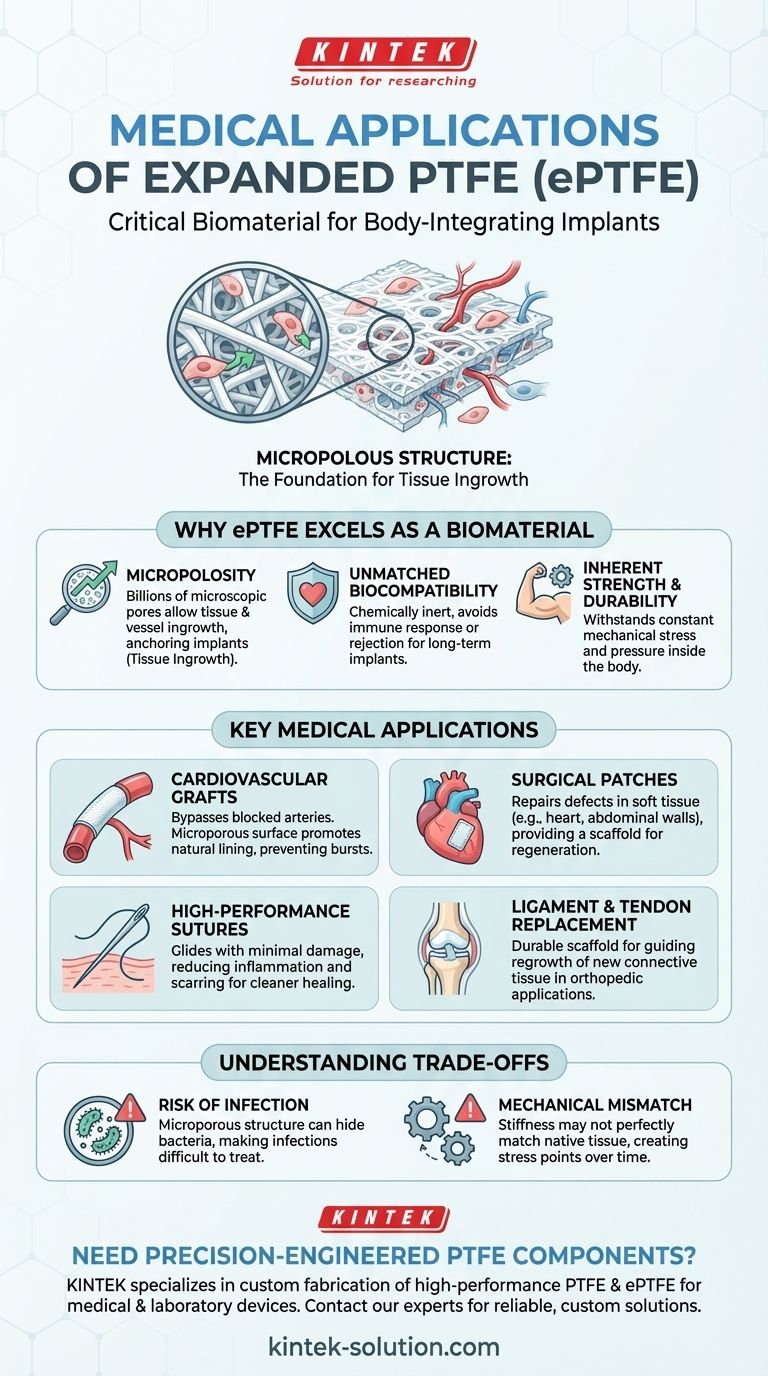

In the medical field, expanded Polytetrafluoroethylene (ePTFE) is a critical biomaterial used for creating implants that integrate with the human body. Its most common applications include artificial blood vessels (vascular grafts), patches for repairing heart and tissue defects, and specialized surgical sutures.

The true value of ePTFE in medicine comes from its unique microporous structure. This network of pores encourages the body's own tissues to grow into the implant, creating a stable, biocompatible integration that solid materials cannot achieve.

Why ePTFE Excels as a Biomaterial

The suitability of ePTFE for medical implants is not based on a single characteristic, but on a combination of powerful properties. These factors work together to ensure safety, durability, and successful integration within the body.

The Power of Microporosity

The defining feature of ePTFE is its structure, which contains billions of microscopic pores. This allows human tissue cells and blood vessels to grow directly into the material over time.

This process, known as tissue ingrowth, effectively anchors the implant in place, creating a living connection between the device and the body.

Unmatched Biocompatibility

ePTFE is biocompatible, meaning it does not provoke a significant immune or inflammatory response from the body.

Because it is chemically inert, it avoids rejection and can remain in the body for long periods without causing adverse reactions, a critical requirement for any permanent implant.

Inherent Strength and Durability

Despite its porous nature, ePTFE is remarkably strong and durable. It can withstand the constant mechanical stresses inside the body, such as the pressure of blood flow in a vascular graft.

This ensures the long-term structural integrity of the medical device, preventing failure over its intended lifespan.

Key Medical Applications in Practice

The unique properties of ePTFE make it the material of choice for several demanding surgical applications where performance and safety are paramount.

Cardiovascular Grafts

Perhaps the most well-known use of ePTFE is in creating artificial blood vessels. These grafts are used to bypass blocked or damaged arteries, restoring blood flow in cardiovascular surgery.

The material's strength prevents the graft from bursting under pressure, while its microporous surface promotes the growth of a thin layer of cells that mimics a natural blood vessel lining.

Surgical Patches

ePTFE is fabricated into sheets or patches used to repair defects in soft tissues. For example, it is used to close holes in the heart (heart patches) or reinforce weakened abdominal walls.

The material provides a strong, biocompatible scaffold that the body can use as a foundation for its own tissue regeneration.

High-Performance Sutures

In delicate procedures, such as vascular or plastic surgery, surgeons use ePTFE sutures.

These sutures glide through tissue with minimal damage and cause very little inflammation, which leads to cleaner healing and reduced scarring compared to traditional suture materials.

Ligament and Tendon Replacement

The strength and biocompatibility of ePTFE also make it suitable for orthopedic applications, including the reconstruction of damaged ligaments and tendons. It provides a durable scaffold to guide the regrowth of new connective tissue.

Understanding the Trade-offs

While ePTFE is an exceptional material, it is not without limitations. Acknowledging these trade-offs is crucial for its appropriate and safe application.

Risk of Infection

The very same microporous structure that encourages tissue ingrowth can also become a potential hiding place for bacteria.

If an infection develops around an ePTFE implant, it can be very difficult to treat with antibiotics alone, sometimes requiring the removal of the device.

Mechanical Mismatch

Although strong, the mechanical properties of ePTFE (like its stiffness) do not perfectly match those of native human tissue.

This mismatch can sometimes create stress points at the connection between the implant and the body, which may be a consideration for very long-term performance.

Making the Right Choice for Your Goal

The decision to use an ePTFE-based device depends entirely on the specific medical challenge being addressed.

- If your primary focus is vascular repair: ePTFE is a gold standard for creating durable artificial blood vessels that integrate effectively with the body.

- If your primary focus is soft tissue reconstruction: An ePTFE patch provides a strong, biocompatible scaffold ideal for repairing defects in organs like the heart.

- If your primary focus is delicate surgical closure: ePTFE sutures are the superior choice for minimizing tissue irritation and promoting clean, low-scar healing.

By understanding its fundamental properties, medical professionals can leverage ePTFE to create life-saving and life-enhancing implants that become a seamless part of the human body.

Summary Table:

| Application | Key Benefit of ePTFE |

|---|---|

| Vascular Grafts | Microporosity encourages tissue ingrowth for stable integration. |

| Surgical Patches | Provides a strong, biocompatible scaffold for tissue repair. |

| Sutures | Causes minimal inflammation for cleaner healing and less scarring. |

| Ligament/Tendon Repair | Durable scaffold that guides the regrowth of connective tissue. |

Need precision-engineered PTFE components for your medical device?

KINTEK specializes in the custom fabrication of high-performance PTFE and ePTFE components, including seals, liners, and labware, for the medical, semiconductor, and laboratory industries. Our expertise in precision production ensures your devices meet the highest standards of biocompatibility and performance, from initial prototypes to high-volume orders.

Contact our experts today to discuss how we can support your next project with reliable, custom PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Three Neck Flasks for Advanced Chemical Applications

People Also Ask

- What are the key properties of PTFE that make it suitable for seals and gaskets? Unlock Superior Sealing Performance

- What temperature range can PTFE expansion bellows withstand? Endure Extremes from -200°C to 260°C

- What are the main advantages of using PTFE heat press sheets? Achieve Flawless, Professional Results

- What types of products are typically made through PTFE paste extrusion? High-Performance Tubing, Hoses & Wire Insulation

- How does the chemical resistance of PTFE O-rings benefit industrial applications? Ensure Unmatched Sealing Integrity

- What are the benefits of PTFE butterfly valves in industrial applications? Enhance Safety, Purity & Efficiency

- What does it mean for Teflon coatings to be non-wetting? Unlock Superior Non-Stick & Chemical Resistance

- What are the advantages of PTFE's chemical resistance in sealing applications? Ensure Unmatched Reliability in Harsh Environments