In the medical field, expanded Polytetrafluoroethylene (ePTFE) is a critical material used for a range of life-saving applications, including synthetic arteries, hernia repair patches, and other implantable devices. Its utility stems from a unique combination of physical properties that allow it to perform safely and reliably inside the human body for extended periods.

The core reason ePTFE is so valuable in medicine is its biocompatibility and structural versatility. The material is chemically inert, meaning the body doesn't reject it, while its tunable microporous structure allows engineers to design it for specific functions, from encouraging tissue integration to creating a perfect barrier.

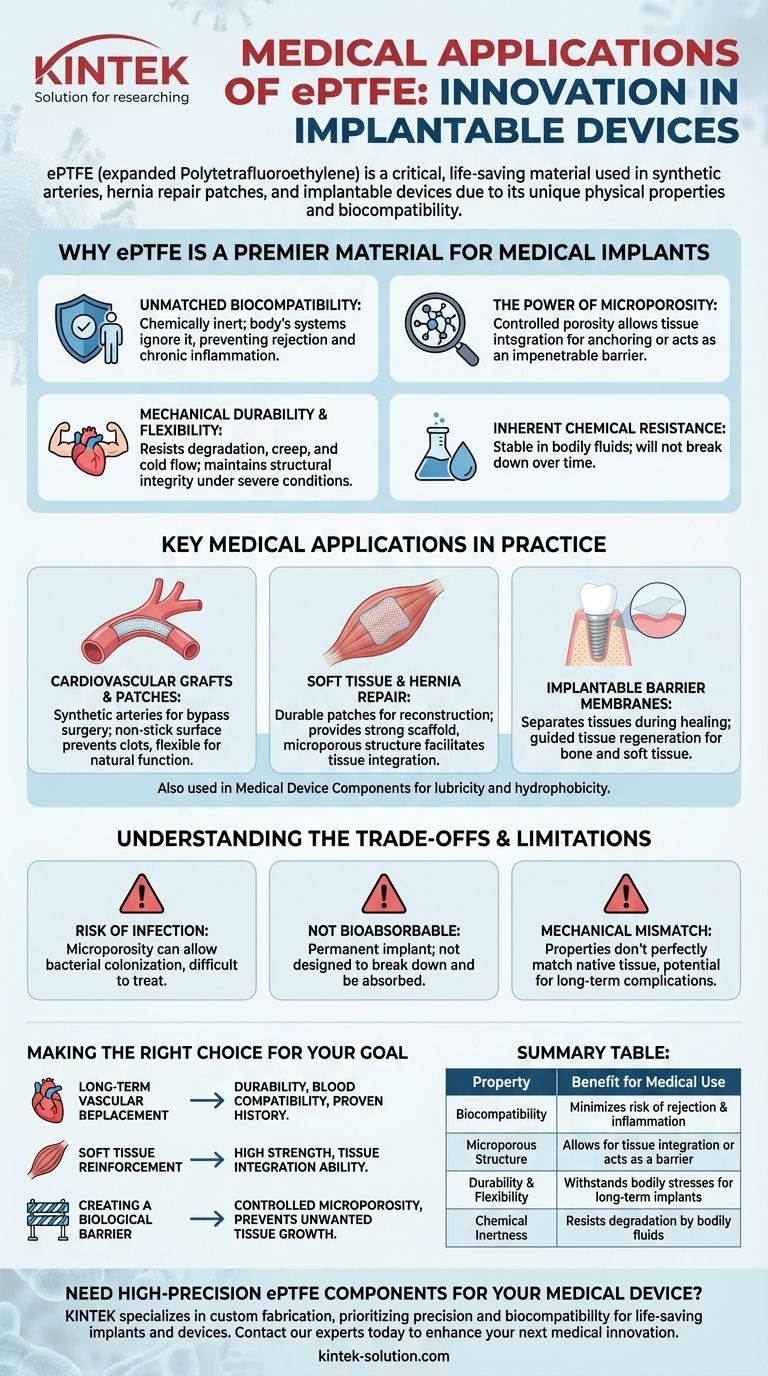

Why ePTFE is a Premier Material for Medical Implants

The selection of a material for medical implantation is governed by a strict set of requirements. ePTFE meets these criteria exceptionally well due to its inherent physical and chemical properties.

Unmatched Biocompatibility

The most important characteristic of any implantable material is its ability to exist within the body without causing an adverse immune reaction.

ePTFE is chemically inert and biocompatible. The human body's systems largely ignore its presence, which is crucial for preventing implant rejection and chronic inflammation.

The Power of Microporosity

The "expanded" nature of ePTFE refers to its internal structure, which consists of solid nodes connected by a web of thin fibrils. This structure is the key to its versatility.

The porosity can be precisely controlled during manufacturing. This allows it to either encourage the body's own cells to grow into the material—anchoring it in place—or act as an impenetrable barrier to prevent unwanted tissue adhesions.

Mechanical Durability and Flexibility

An implant must withstand the constant stresses of the human body for years, if not decades.

ePTFE is highly resistant to mechanical degradation, creep, and cold flow. It maintains its structural integrity under severe conditions, which is vital for applications like vascular grafts that flex with every heartbeat.

Inherent Chemical Resistance

Bodily fluids can be corrosive to many materials, but ePTFE remains stable. Its chemical resistance ensures that it will not break down over time, maintaining its function and preventing the release of harmful substances.

Key Medical Applications in Practice

The unique properties of ePTFE translate directly into its use in several critical medical and surgical fields.

Cardiovascular Grafts and Patches

ePTFE is widely used to create synthetic arteries (vascular grafts) for bypass surgery. Its smooth, non-stick surface helps prevent blood clots, while its flexibility allows it to function like a natural blood vessel.

Soft Tissue and Hernia Repair

For hernia repair and other soft tissue reconstruction, ePTFE is manufactured into durable patches. The material provides a strong, permanent scaffold that supports the weakened tissue, and its microporous structure can facilitate integration with surrounding tissue.

Implantable Barrier Membranes

In dental and reconstructive surgery, ePTFE membranes are used to separate different types of tissue during the healing process. This guided tissue regeneration ensures that bone and soft tissues heal correctly without interfering with each other.

Medical Device Components

Beyond long-term implants, ePTFE is also used for disposable or external components. Its lubricity and hydrophobicity make it ideal for instrument covers and the lining of delivery tubes and catheters.

Understanding the Trade-offs and Limitations

While ePTFE is an exceptional material, no solution is perfect. Understanding its limitations is critical for its proper application.

Risk of Infection

The very microporosity that makes ePTFE so useful can also pose a risk. If bacteria colonize the porous structure, the resulting infection can be very difficult to treat with antibiotics, sometimes requiring removal of the implant.

Not Bioabsorbable

ePTFE is a permanent implant. It is not designed to be broken down and absorbed by the body. This is a disadvantage in applications where only temporary support is needed to allow the body to heal itself.

Mechanical Mismatch

Although flexible, the mechanical properties of ePTFE are not a perfect match for native human tissue. This difference can create stress at the points where a graft is sutured to a natural vessel, which can be a factor in long-term complications.

Making the Right Choice for Your Goal

The decision to use an ePTFE-based device depends entirely on the specific medical challenge you are trying to solve.

- If your primary focus is long-term vascular replacement: ePTFE is a leading choice due to its durability, blood-compatible surface, and proven clinical history.

- If your primary focus is soft tissue reinforcement: The material's high strength and ability to integrate with the body's own tissue make it ideal for applications like hernia repair.

- If your primary focus is creating a biological barrier: The controlled microporosity of ePTFE is perfectly suited for preventing unwanted tissue growth in complex surgical and dental procedures.

Ultimately, the unique physical and chemical properties of ePTFE make it an indispensable tool for solving some of modern medicine's most complex challenges.

Summary Table:

| Property | Benefit for Medical Use |

|---|---|

| Biocompatibility | Minimizes risk of rejection and inflammation |

| Microporous Structure | Allows for tissue integration or acts as a barrier |

| Durability & Flexibility | Withstands bodily stresses for long-term implants |

| Chemical Inertness | Resists degradation by bodily fluids |

Need high-precision ePTFE components for your medical device?

KINTEK specializes in the custom fabrication of PTFE and ePTFE components for the medical industry. From prototypes to high-volume production, we prioritize the precision and biocompatibility required for life-saving implants and devices.

Contact our experts today to discuss how our materials expertise can enhance your next medical innovation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Three Neck Flasks for Advanced Chemical Applications

People Also Ask

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- How do PTFE expansion bellows address pipe misalignment? Protect Your Piping System from Stress and Failure

- What are the characteristics of a high-speed, low-pressure PTFE seal profile? Maximize Performance at 5,000 SFPM

- Can PTFE rotary shaft seals be customized for specific needs? Tailor for Speed, Temperature & Chemical Resistance

- What are the primary challenges in molding PTFE? Overcome High Melt Viscosity and Sintering Complexities

- In which applications are PTFE bellows commonly utilized? Essential Protection for Demanding Industries

- What are some everyday uses of Teflon sheets? From Cookware to Cars, Discover Its Hidden Role

- What are the different types of PTFE diaphragms and their applications? Optimize Your Chemical Processing System