The defining properties of PTFE gaskets are their exceptional chemical inertness, a remarkably wide operational temperature range, and an extremely low coefficient of friction. This unique combination of characteristics makes Polytetrafluoroethylene (PTFE) one of the most versatile and reliable sealing materials available for demanding industrial environments.

While many materials excel in one specific area, PTFE's value comes from its rare ability to simultaneously resist aggressive chemicals and extreme temperatures without degrading. Understanding this synergy is the key to leveraging it for maximum reliability.

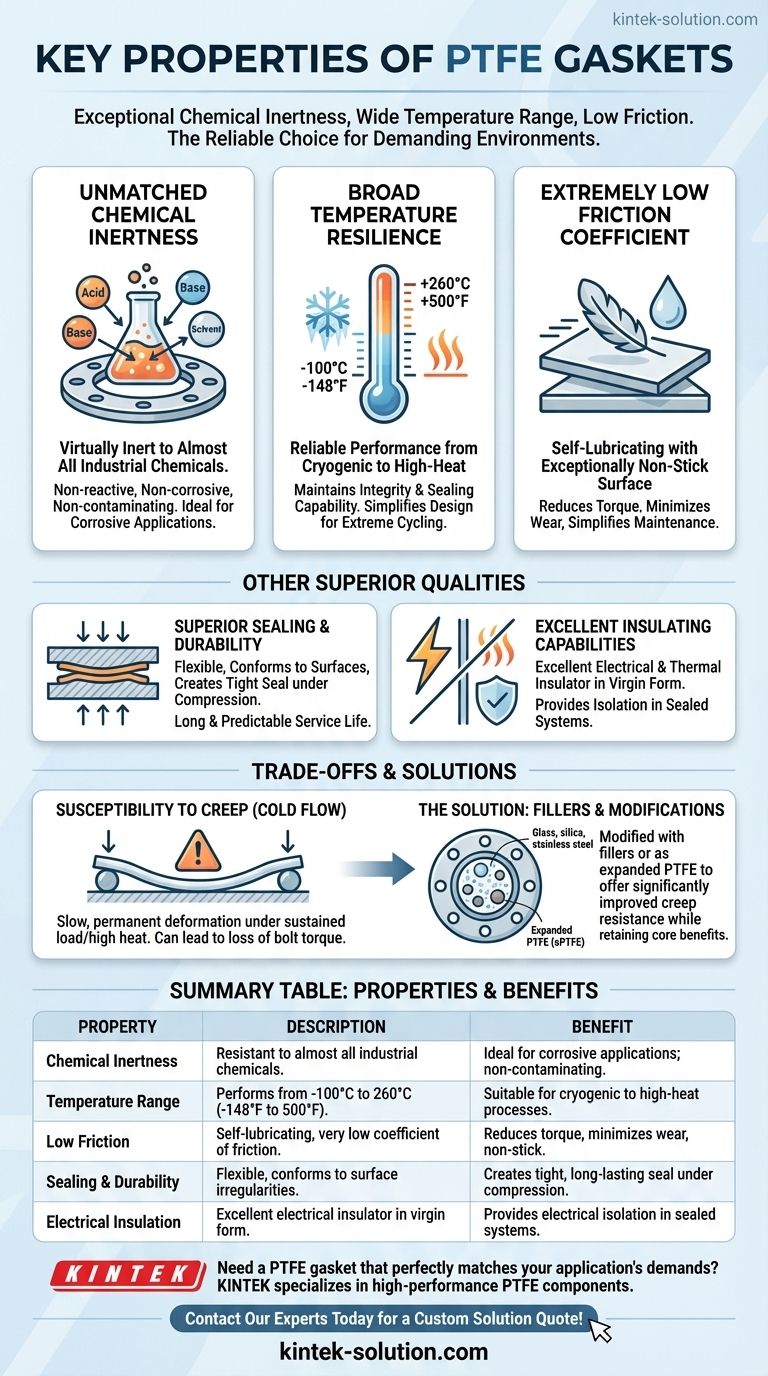

The Core Properties of PTFE Gaskets Explained

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals and solvents, making it a "go-to" material for corrosive applications. Its non-reactive and non-corrosive nature means it will not degrade when exposed to strong acids, bases, or other aggressive substances.

This also makes it non-contaminating, non-wetting, and odorless, a critical feature for applications in the food, beverage, and pharmaceutical industries where purity is paramount.

Broad Temperature Resilience

PTFE gaskets perform reliably across a vast temperature spectrum. They maintain their integrity and sealing capability from cryogenic conditions around -100°C (-148°F) up to high-heat applications of 260°C (500°F).

This allows a single gasket material to be specified for processes that involve extreme temperature cycling, simplifying design and inventory.

Extremely Low Friction Coefficient

With one of the lowest friction values of any solid material, PTFE is inherently self-lubricating. Its surface is exceptionally non-stick.

This property reduces the torque required to tighten bolted joints, minimizes wear between flange surfaces, and simplifies cleaning and maintenance.

Superior Sealing and Durability

PTFE is flexible and can conform to surface irregularities, creating a tight and durable seal under compression.

Its inherent resistance to chemical attack and temperature extremes ensures a long and predictable service life, even in the harshest operating conditions.

Excellent Insulating Capabilities

In its virgin form, PTFE serves as an excellent electrical insulator, making it valuable for applications where electrical isolation is necessary.

It also provides effective thermal insulation, helping to maintain temperature stability within a sealed system.

Understanding the Trade-offs and Limitations

Susceptibility to Creep (Cold Flow)

The primary limitation of virgin PTFE is its tendency to "creep" or cold flow under sustained compressive loads, especially at elevated temperatures.

This slow, permanent deformation can lead to a loss of bolt torque over time, potentially compromising the integrity of the seal if not accounted for in the design.

The Role of Fillers and Modifications

To counteract creep and enhance mechanical properties, PTFE is often modified with fillers like glass, silica, or stainless steel.

Common variants like expanded PTFE (ePTFE) are specifically engineered to offer significantly improved creep resistance while retaining the material's core chemical and thermal benefits.

Making the Right Choice for Your Goal

Choosing the correct gasket depends entirely on the specific demands of your system.

- If your primary focus is handling aggressive chemicals at moderate pressures: Standard virgin PTFE offers the highest purity and maximum chemical resistance.

- If your primary focus is maintaining a seal in high-pressure or thermally cycling systems: An expanded or filled PTFE gasket is required to resist creep and ensure long-term integrity.

- If your primary focus is preventing contamination in food or pharmaceutical applications: The non-stick, non-wetting, and inert nature of virgin PTFE is the ideal choice.

Selecting the right PTFE variant ensures you harness its strengths for unparalleled reliability in the most challenging environments.

Summary Table:

| Property | Description | Benefit |

|---|---|---|

| Chemical Inertness | Resistant to almost all industrial chemicals and solvents. | Ideal for corrosive applications; non-contaminating. |

| Temperature Range | Performs from -100°C to 260°C (-148°F to 500°F). | Suitable for cryogenic to high-heat processes. |

| Low Friction | Self-lubricating with a very low coefficient of friction. | Reduces torque, minimizes wear, and is non-stick. |

| Sealing & Durability | Flexible and conforms to surface irregularities. | Creates a tight, long-lasting seal under compression. |

| Electrical Insulation | Excellent electrical insulator in virgin form. | Provides electrical isolation in sealed systems. |

Need a PTFE gasket that perfectly matches your application's demands?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including seals, gaskets, liners, and labware. Whether your priority is handling aggressive chemicals in the semiconductor industry, ensuring purity in medical or pharmaceutical applications, or achieving reliable seals in demanding industrial environments, our expertise in precision production and custom fabrication—from prototypes to high-volume orders—ensures you get a solution that delivers maximum reliability and longevity.

Contact our experts today to discuss your specific requirements and get a custom solution quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the installation benefits of PTFE compensators compared to metal alternatives? Achieve Faster, Safer, and More Cost-Effective Installation

- What are the benefits of different spring types used in PTFE seals? Optimize Sealing Performance & Lifespan

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What temperature range can PTFE balls typically withstand? From -200°C to +260°C with Key Limitations

- How can PTFE be modified for different applications? Tailor Performance with Fillers and Processing

- In what industries are Teflon lip seals commonly used? Essential for Extreme Chemical & Temperature Resistance

- What is the importance of balancing cost and performance when selecting PTFE packing? Maximize Uptime & Minimize Total Cost

- What materials are offered for PTFE bushes? Choose the Right Filled PTFE Compound for Your Application