At their core, bronze bushings are prized for their exceptional strength, high load capacity, and inherent resistance to wear, heat, and corrosion. Composed of a copper and tin alloy, these components offer remarkable durability and often feature self-lubricating properties, which significantly reduces maintenance requirements in demanding mechanical applications.

The central value of a bronze bushing lies in its ability to provide a durable, low-maintenance bearing solution for high-load, high-temperature, and corrosive environments where other materials would quickly fail.

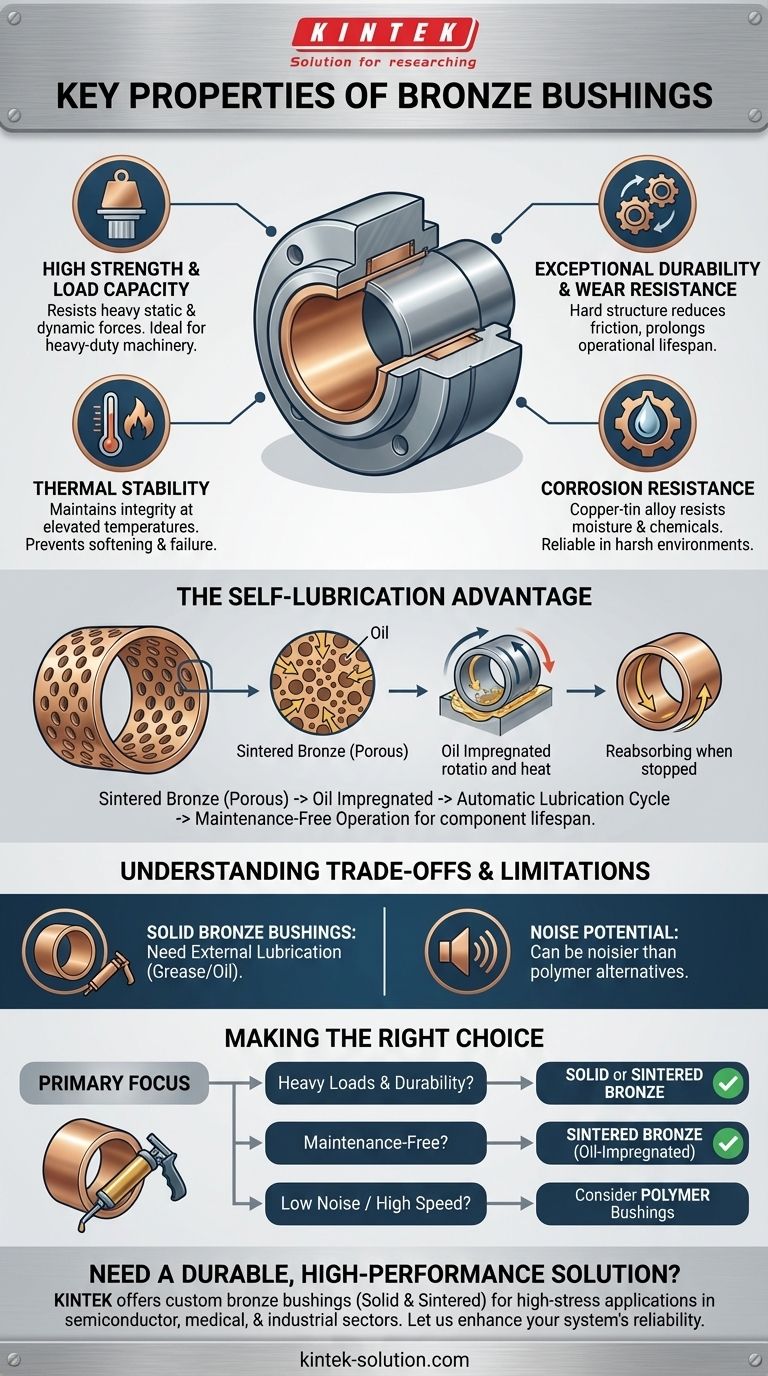

Core Mechanical Properties Explained

To understand if a bronze bushing is right for your project, it's essential to look beyond the labels and see how each property functions in a real-world system.

High Strength and Load Capacity

Bronze alloys possess high compressive strength. This allows them to withstand heavy static and dynamic loads without deforming or failing.

This makes them ideal for applications like construction equipment, industrial machinery, and automotive suspensions where significant forces are constantly at play.

Exceptional Durability and Wear Resistance

The inherent hardness and material structure of bronze provide excellent resistance to friction and wear. This translates directly to a longer operational lifespan for the bushing and the shaft it supports.

A long service life means fewer replacements, less downtime, and lower long-term costs.

Thermal Stability

Bronze maintains its structural integrity and hardness at elevated temperatures that would cause many plastics or softer metals to soften and fail.

This property is critical for machinery where heat is a natural byproduct of operation, such as in engines, pumps, and industrial gearboxes.

Corrosion Resistance

The copper content in bronze gives it a natural resistance to corrosion from atmospheric moisture, water, and many industrial chemicals.

This makes bronze bushings a reliable choice for marine applications, outdoor equipment, and chemical processing machinery where environmental exposure is a constant concern.

The Self-Lubrication Advantage

One of the most significant features of certain bronze bushings is their ability to operate without external lubrication, which fundamentally changes their maintenance profile.

How Self-Lubrication Works

Many bronze bushings are sintered, a process that creates a porous material. This porous structure is then impregnated with oil.

During operation, the shaft's rotation generates slight heat, which draws the oil out of the pores and onto the bearing surface, creating a lubricating film. When the machine stops, the oil is reabsorbed, ready for the next cycle.

The Benefit of Low Maintenance

This self-lubricating mechanism makes the component effectively "maintenance-free" for its intended lifespan. It eliminates the need for regular greasing, which is invaluable for hard-to-reach locations or sealed-for-life assemblies.

Understanding the Trade-offs and Limitations

While powerful, bronze bushings are not a universal solution. Their effectiveness depends on understanding their limitations and choosing the right type for the job.

The Need for Lubrication in Some Cases

Not all bronze bushings are self-lubricating. Solid bronze bushings lack the porous, oil-impregnated structure and require an external source of lubrication, such as grease or oil, to function correctly and prevent seizure.

Potential for Noise

As a metal-on-metal bearing system, bronze bushings can be noisier during operation compared to alternatives like polymer or composite bushings. This can be a significant factor in noise-sensitive applications.

Making the Right Choice for Your Application

Selecting the correct bushing requires matching its properties to your primary operational goal.

- If your primary focus is heavy loads and durability: A solid or sintered bronze bushing is an excellent choice due to its superior strength and wear resistance.

- If your primary focus is maintenance-free operation: An oil-impregnated sintered bronze bushing is the definitive solution.

- If your primary focus is low noise or high speed: You may need to consider polymer bushings, as bronze can be noisy and may have speed limitations compared to other materials.

Ultimately, the robust and reliable nature of bronze makes it a foundational component in high-stress mechanical systems.

Summary Table:

| Key Property | Benefit | Ideal For |

|---|---|---|

| High Strength & Load Capacity | Withstands heavy static/dynamic loads without deforming. | Construction equipment, industrial machinery, automotive suspensions. |

| Wear Resistance & Durability | Long service life, reduces downtime and replacement costs. | High-friction, continuous operation environments. |

| Thermal Stability | Maintains integrity and hardness at elevated temperatures. | Engines, pumps, gearboxes, and other high-heat applications. |

| Corrosion Resistance | Resists moisture, water, and many chemicals. | Marine applications, outdoor equipment, chemical processing. |

| Self-Lubrication (Sintered) | Maintenance-free operation for the component's lifespan. | Hard-to-reach locations or sealed assemblies. |

Need a Durable, High-Performance Bushing Solution?

At KINTEK, we understand that the right bushing is critical to your machinery's reliability and efficiency. Our expertise in precision manufacturing extends to high-performance components for the semiconductor, medical, laboratory, and industrial sectors.

Whether you require a robust solid bronze bushing for extreme loads or a maintenance-free, oil-impregnated sintered bronze bushing, we can deliver. We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit and optimal performance for your specific application.

Let us help you enhance your system's durability and reduce maintenance costs.

Contact KINTEK today for a consultation and let's discuss your project requirements.

Visual Guide

Related Products

People Also Ask

- How are PTFE-lined pipes manufactured? A Guide to Durable, Corrosion-Resistant Piping

- Why are extruded PTFE rods popular in plumbing systems? Superior Chemical & Thermal Resistance

- Why are PTFE lined pipes considered essential for certain industries? Unmatched Corrosion Resistance & Purity

- What factors affect the lifespan of PTFE tubing and rods? Ensure Long-Term Reliability for Your Critical Applications

- How are extruded PTFE rods manufactured? A Look at the Unique Paste Extrusion & Sintering Process