At its core, a PTFE lined butterfly valve consists of four primary components: the valve body, the internal disc, the stem, and the critical PTFE (polytetrafluoroethylene) liner that serves as both the seat and a protective barrier. While the body, disc, and stem provide the mechanical structure and operation common to all butterfly valves, it is the PTFE liner that gives this valve its specialized capabilities for handling highly corrosive and high-purity media.

The key takeaway is that a PTFE lined butterfly valve is not merely a standard valve with a coating. It is an engineered system where a thick, resilient PTFE liner forms the primary sealing surface and isolates all other components from the process fluid, providing exceptional chemical resistance at the cost of requiring more precise installation.

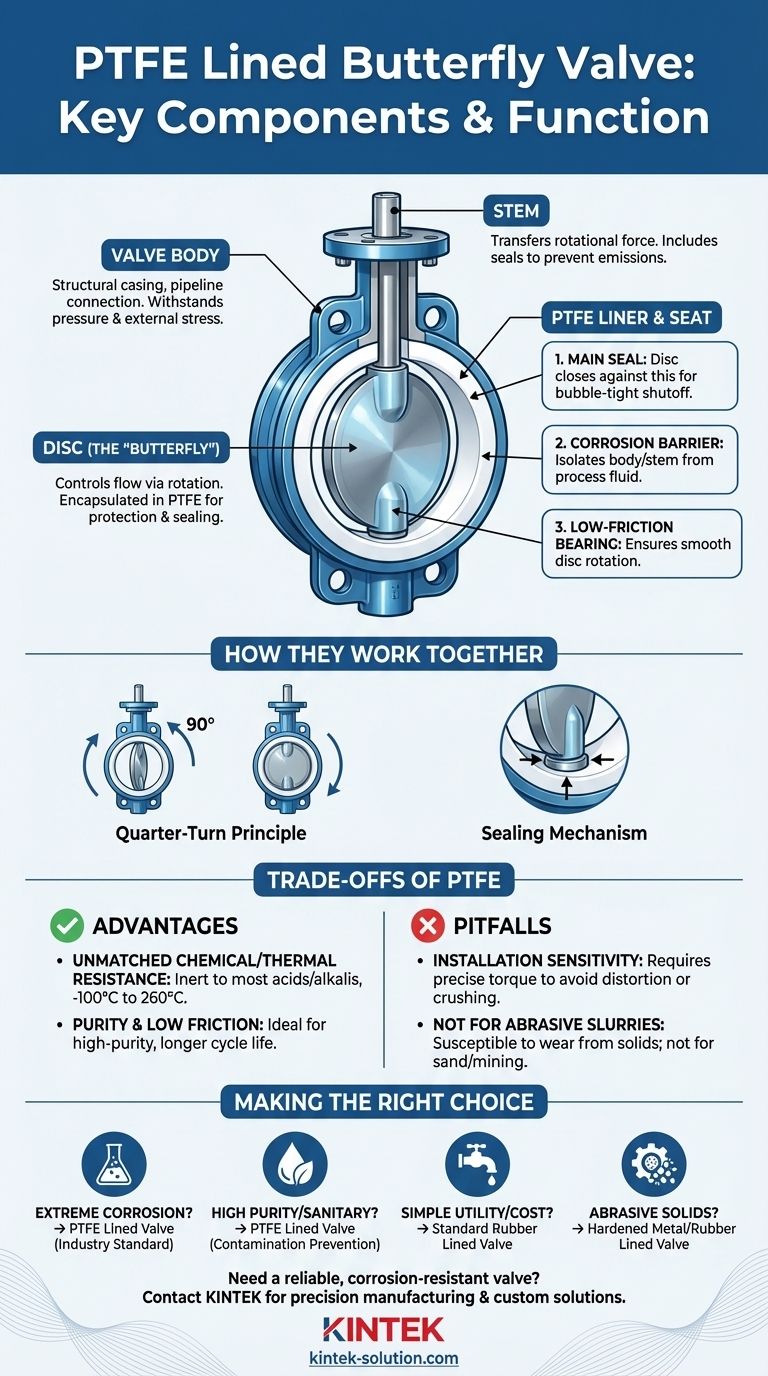

Anatomy of a PTFE Lined Butterfly Valve

Understanding this valve requires looking at how each component contributes to its overall function, especially the central role played by the PTFE liner.

The Valve Body

The body is the external casing of the valve. It provides the structural backbone, houses the internal components, and connects to the surrounding pipeline. Its primary job is to contain the system pressure and withstand external mechanical stresses.

The Disc (The "Butterfly")

This is the circular component located in the center of the valve that rotates to control flow. In a PTFE lined valve, the disc is often encapsulated in PTFE or made from a highly resistant alloy to provide a secondary layer of protection should the liner be compromised. The edge of the disc is precisely machined to press into the soft PTFE seat, creating the seal.

The Stem

The stem is a rod that connects the disc to an external actuator or handwheel. It transfers the rotational force needed to open or close the valve. In high-performance designs, the stem includes its own seals to prevent process fluid from escaping to the atmosphere, a critical feature for eliminating fugitive emissions.

The PTFE Liner and Seat

This is the most important component and the valve's key differentiator. The liner is a thick, non-metallic sleeve that fits inside the valve body. It performs three crucial functions simultaneously:

- It is the main seal: The disc closes against this soft liner to provide a bubble-tight shutoff.

- It is the corrosion barrier: The liner completely isolates the valve body and stem from the process fluid, allowing for the use of less expensive body materials like carbon steel.

- It is a low-friction bearing: PTFE's naturally low coefficient of friction ensures smooth disc rotation, reducing the torque required for operation.

How These Components Work Together

The design's elegance lies in its simplicity. The components unite to deliver reliable flow control based on a straightforward mechanical principle.

The Quarter-Turn Principle

The valve operates on a quick shut-off principle. The stem rotates the disc 90 degrees within the pipe. When the disc is parallel to the flow, the valve is fully open. When the disc is rotated to be perpendicular to the flow, it is fully closed.

The Sealing Mechanism

Sealing integrity is achieved when the outer edge of the disc compresses into the resilient PTFE seat. This action effectively blocks the fluid path, preventing internal leakage. The design also seals the valve to the pipe flanges, creating a secure connection within the piping system and preventing external leaks.

Understanding the Trade-offs of PTFE

While powerful, the PTFE design comes with specific advantages and considerations that you must weigh for your application.

Advantage: Unmatched Chemical and Thermal Resistance

PTFE is virtually inert to most chemicals, including strong acids, alkalis, and oxidants. It also performs exceptionally well across a wide temperature range, from as low as -100°C (-148°F) to as high as 260°C (500°F), making it suitable for extreme process conditions.

Advantage: Purity and Low Friction

The material's inertness and smooth surface make it ideal for high-purity applications in the pharmaceutical and food production industries, as it will not contaminate the process media. The low friction also leads to a longer cycle life and easier automation.

Pitfall: Installation Sensitivity

This is the most critical consideration. Because PTFE is a relatively soft material, the valve is highly sensitive to improper installation. Uneven bolt tightening can distort the valve body and liner, leading to leaks. Overtorquing can crush the PTFE seat, destroying its ability to seal properly. Always follow the manufacturer's specific torque patterns and values.

Pitfall: Not Ideal for Abrasive Slurries

While PTFE is durable, it is a polymer, not a hard metal or ceramic. It can be susceptible to wear and damage from highly abrasive media like sand, mining slurries, or other solids. In these applications, a metal-seated or rubber-lined valve designed for abrasion may be a more robust choice.

Making the Right Choice for Your Application

Selecting the correct valve requires matching its capabilities to your specific operational needs. Use the following points as a guide.

- If your primary focus is extreme chemical corrosion: The PTFE lined butterfly valve is an industry standard and often the most reliable choice for aggressive media.

- If your primary focus is high-purity or sanitary processes: The inert nature of the PTFE liner makes this valve an excellent option to prevent media contamination.

- If your primary focus is cost on a simple utility (like water): A standard valve with a less expensive EPDM or Buna-N rubber liner is likely a more cost-effective and perfectly suitable solution.

- If your primary focus is handling abrasive solids: You should investigate specialized severe-service valves with hardened metal seats or abrasion-resistant rubber liners instead.

By understanding the function of each component, you can confidently determine where a PTFE lined butterfly valve is the right technical solution for your system.

Summary Table:

| Component | Primary Function | Key Characteristic |

|---|---|---|

| Valve Body | Structural casing and pipeline connection | Withstands system pressure and external stress |

| Disc | Controls flow by rotating | Often PTFE-encapsulated; creates seal against liner |

| Stem | Transfers rotational force to the disc | Includes seals to prevent fugitive emissions |

| PTFE Liner | Primary seal and corrosion barrier | Isolates fluid from valve body; provides chemical resistance |

Need a reliable, corrosion-resistant valve for your critical process?

At KINTEK, we specialize in precision manufacturing of PTFE components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a PTFE lined butterfly valve perfectly engineered for your specific media, pressure, and purity requirements.

Contact KINTEK today to discuss your application and receive a tailored solution that guarantees performance and durability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability