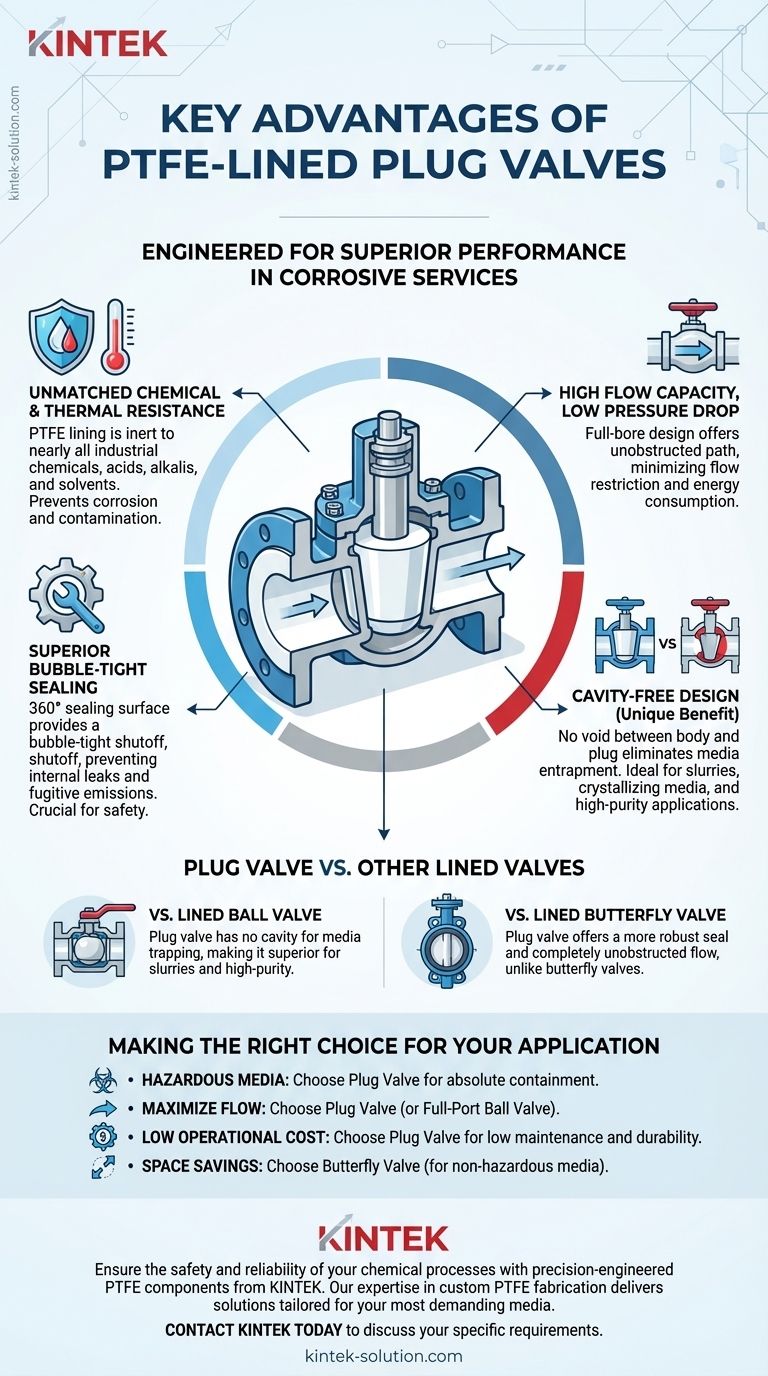

PTFE-lined plug valves are engineered for superior performance in highly corrosive and demanding chemical services. Their key advantages stem from a combination of material science and mechanical design, providing exceptional chemical resistance, bubble-tight sealing, high flow capacity, minimal maintenance requirements, and broad operational versatility.

While many valve types can handle chemicals, the PTFE-lined plug valve's distinct advantage lies in its robust, cavity-free design. This ensures unparalleled sealing integrity and reliability, making it the preferred choice for applications where leaks are not an option.

The Core Advantages Explained

The value of a PTFE-lined plug valve is best understood by examining how its design and materials work together to solve critical industrial challenges.

Unmatched Chemical and Thermal Resistance

The primary advantage is the PTFE (polytetrafluoroethylene) lining itself. This fluoropolymer is inert to nearly all industrial chemicals and solvents, including strong acids, alkalis, and toxic media.

This comprehensive resistance ensures the valve's structural integrity is not compromised by the fluid, preventing corrosion that could lead to failures or product contamination.

Superior Bubble-Tight Sealing

PTFE-lined plug valves are renowned for their exceptional sealing capabilities. The design features a large, 360-degree sealing surface between the PTFE-encapsulated plug and the PTFE body liner.

This continuous contact creates a bubble-tight shutoff that prevents both internal (downstream) and external (fugitive) emissions. This is a critical safety feature when handling hazardous or high-purity substances.

High Flow Capacity with Minimal Pressure Drop

Most PTFE-lined plug valves feature a full-bore (or full-port) design. This means the opening through the valve is the same diameter as the connecting pipe.

This unobstructed path minimizes flow restriction and pressure drop across the valve, improving overall system efficiency and reducing energy consumption from pumps.

Low Maintenance and Extended Lifespan

The non-stick, low-friction properties of PTFE are a significant operational benefit. Media does not adhere to the valve's internal surfaces, preventing buildup that could impede operation or contaminate the process.

Furthermore, the low coefficient of friction reduces the torque required to operate the valve. This minimizes wear on the components and actuation system, leading to a longer service life and reduced maintenance needs.

Understanding the Trade-offs: Plug vs. Other Lined Valves

While PTFE-lined plug valves are a top-tier solution, selecting the right valve requires comparing them to other common alternatives for corrosive services.

Plug Valve vs. Lined Ball Valve

Lined ball valves also offer excellent chemical resistance and high flow capacity. The key difference lies in the internal design.

A ball valve has a cavity between the body and the ball where media can become trapped. In a plug valve, there is no such void, making it a superior choice for slurries, crystallizing media, or high-purity applications where contamination is a concern.

Plug Valve vs. Lined Butterfly Valve

Lined butterfly valves are often more compact, lightweight, and cost-effective, especially in larger pipe diameters. They are well-suited for simple on/off applications where space is a constraint.

However, a plug valve provides a more robust and reliable seal, making it the safer option for highly hazardous chemicals. The plug valve's full-bore design also offers a completely unobstructed flow path, whereas a butterfly valve's disc is always present in the flow, causing a greater pressure drop.

Making the Right Choice for Your Application

Your selection should be driven by the most critical performance requirement of your specific system.

- If your primary focus is absolute containment of hazardous or high-purity media: The PTFE-lined plug valve is the superior choice due to its robust, cavity-free, and bubble-tight sealing mechanism.

- If your primary focus is maximizing flow with minimal pressure loss: The full-bore design of a PTFE-lined plug valve makes it an excellent choice, on par with a full-port ball valve.

- If your primary focus is reducing long-term operational costs: The low-maintenance, non-stick, and durable design of a PTFE-lined plug valve offers a low total cost of ownership in demanding services.

- If your primary focus is space and weight savings in a large-diameter system: A PTFE-lined butterfly valve may be a more practical and economical solution, provided the media is not hazardous.

By understanding these core distinctions, you can select the valve that provides not just compatibility, but long-term safety, efficiency, and reliability for your specific process.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Chemical Resistance | Inert to nearly all acids, alkalis, and solvents |

| Bubble-Tight Seal | 360-degree sealing prevents leaks and fugitive emissions |

| High Flow Capacity | Full-bore design minimizes pressure drop |

| Low Maintenance | Non-stick PTFE reduces wear and extends lifespan |

| Cavity-Free Design | Ideal for slurries and high-purity applications, preventing media entrapment |

Ensure the safety and reliability of your chemical processes with precision-engineered PTFE components from KINTEK.

Our expertise in custom PTFE fabrication—from seals and liners to complex labware—ensures you get a solution perfectly tailored to handle your most demanding media in the semiconductor, medical, laboratory, and industrial sectors. We deliver from prototypes to high-volume orders with a focus on precision and durability.

Contact KINTEK today to discuss your specific valve or component requirements and discover how our PTFE solutions can enhance your system's performance and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How has the relationship between machinery manufacturers and bearing suppliers evolved regarding PTFE-faced thrust bearings?

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does Teflon lining on the internal wall of valves improve performance? Enhance Valve Life and Purity

- What are the benefits of PTFE bushes over plastic bushings? Superior Performance for Harsh Environments

- Where are PTFE energized seals used in oil and gas operations? Essential Sealing Solutions for Harsh Environments

- What is the purpose of PTFE etching? Unlock Bondable Surfaces for Your Components

- Why is a thin element design preferred for PTFE seals from a cost standpoint? Minimize Initial Cost & Maximize Long-Term Value

- What are the key advantages of using PTFE envelope gaskets? Superior Sealing for Aggressive Chemical & High-Pressure Applications