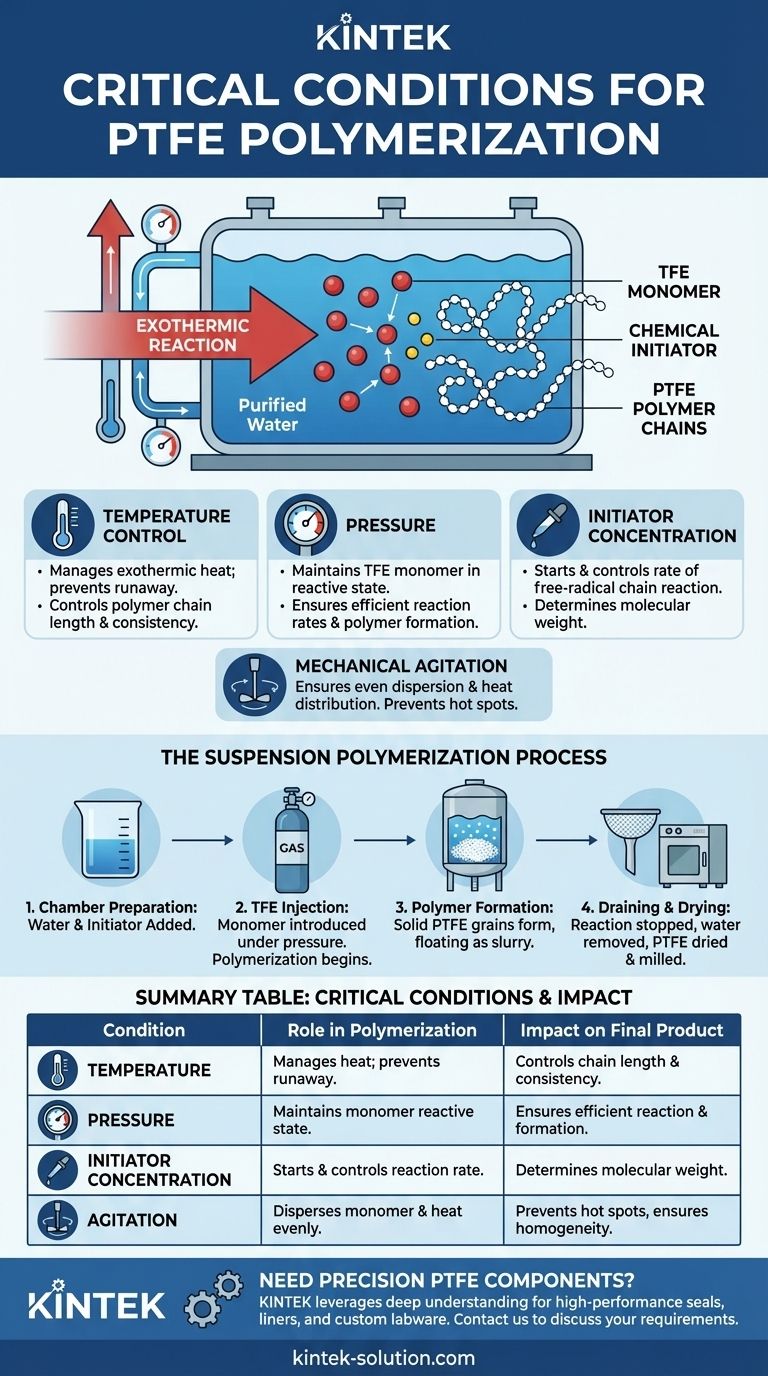

The critical conditions for the polymerization of Polytetrafluoroethylene (PTFE) are the precise control of temperature, pressure, and the concentration of a chemical initiator. This process takes place in a reaction chamber filled with purified water, where tetrafluoroethylene (TFE) monomer is introduced and converted into long polymer chains through a free-radical reaction.

The core challenge in PTFE manufacturing is not simply setting static conditions, but actively managing a dynamic and exothermic chemical reaction. Success hinges on continuously controlling heat and agitation to guide the formation of the polymer chains, directly influencing the properties of the final material.

The Foundation: Free-Radical Polymerization

The creation of PTFE is a classic example of free-radical polymerization. Understanding this core mechanism is key to appreciating why each manufacturing condition is so critical.

The Monomer: Tetrafluoroethylene (TFE)

The process begins with the monomer, TFE. This is the fundamental chemical building block that will be linked together thousands of times to form the final PTFE polymer.

The Initiator (Catalyst)

A reaction initiator, or catalyst, is added to the purified water in the reaction chamber. Its sole purpose is to start the chain reaction by splitting TFE monomers and creating highly reactive "free radicals."

The Reaction Environment

These free radicals rapidly bond with other TFE monomers, initiating the formation of long, stable polymer chains. The entire reaction occurs within purified water, which acts as a medium to suspend the reactants and help manage temperature.

Key Process Parameters and Their Control

Achieving the desired PTFE structure requires rigorous management of several interdependent variables during the polymerization stage, specifically within a method known as suspension polymerization.

Temperature Control

The polymerization reaction is highly exothermic, meaning it generates significant heat. Cold water is continuously circulated around the reaction chamber to remove this heat.

Without precise temperature control, the reaction could accelerate, leading to inconsistent polymer chain lengths or even unsafe conditions.

Mechanical Agitation

The reaction chamber is mechanically shaken or agitated throughout the process. This ensures that the TFE monomer is evenly dispersed in the water and maintains contact with the initiator.

Proper agitation also contributes to uniform heat distribution, preventing localized hot spots within the reactor.

Stopping the Reaction

The process is not allowed to run to completion. Instead, it is deliberately stopped after a specific weight of PTFE has been produced. This is a critical control point for ensuring the final product meets its target specifications.

The Suspension Polymerization Process

While other methods like dispersion polymerization exist, the suspension process clearly illustrates the interplay of these critical conditions.

Step 1: Chamber Preparation

A reaction chamber is filled with purified water, and the chosen initiator agent is added and mixed.

Step 2: TFE Injection

Liquid or gaseous TFE is pumped under pressure into the sealed chamber. Upon meeting the initiator, polymerization begins almost immediately.

Step 3: Polymer Formation

As the TFE polymerizes, it forms solid white grains of PTFE. Because PTFE is denser than water, these grains float to the surface, creating a slurry.

Step 4: Draining and Drying

Once the target weight is reached, the reaction is stopped, and the water is drained away. This leaves behind the raw, stringy, or granular PTFE, which is then dried and milled into a usable powder.

How Process Conditions Define the Final Product

The choice and control of these parameters are not arbitrary; they are the levers that determine the final characteristics of the PTFE resin.

- If your primary focus is producing granular PTFE resins: Suspension polymerization, with its specific controls on temperature and agitation, is the required pathway.

- If your priority is process stability and safety: Meticulous control over the cooling system is non-negotiable to manage the exothermic heat of the reaction.

- If consistency in polymer molecular weight is critical: The precise concentration of the initiator and the exact point at which the reaction is stopped are the most important variables to manage.

Ultimately, these carefully managed conditions are what transform a simple gas into one of the world's most versatile and high-performance polymers.

Summary Table:

| Critical Condition | Role in PTFE Polymerization | Impact on Final Product |

|---|---|---|

| Temperature | Manages the highly exothermic reaction; prevents runaway. | Controls polymer chain length and consistency. |

| Pressure | Maintains TFE monomer in a reactive state within the chamber. | Ensures efficient reaction rates and polymer formation. |

| Initiator Concentration | Starts and controls the rate of the free-radical chain reaction. | Directly determines the molecular weight of the PTFE resin. |

| Agitation | Ensures even dispersion of monomer and uniform heat distribution. | Prevents hot spots and guarantees a homogeneous product. |

Need Precision PTFE Components?

The rigorous control detailed above is exactly what KINTEK brings to every project. We leverage our deep understanding of PTFE's properties to manufacture high-performance seals, liners, and custom labware that meet the demanding standards of the semiconductor, medical, and industrial sectors.

Let us put our expertise to work for you. Whether you require a custom prototype or a high-volume production run, our team is equipped to deliver components with the consistency and reliability your application demands.

Contact KINTEK today to discuss your specific requirements and discover how our precision PTFE solutions can enhance your products.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications