At its core, expanded PTFE provides superior cleanliness because it is manufactured from 100% pure, virgin Polytetrafluoroethylene (PTFE). This inherent purity means the gasket material is chemically inert, non-toxic, and will not leach contaminants into the process media, directly protecting product integrity and preventing cross-contamination between batches.

The primary cleanliness benefit of an expanded PTFE gasket isn't an added feature—it's a fundamental property of the material itself. Its chemical inertness and stable physical structure ensure that the only thing the gasket contributes to your system is a reliable, non-contaminating seal.

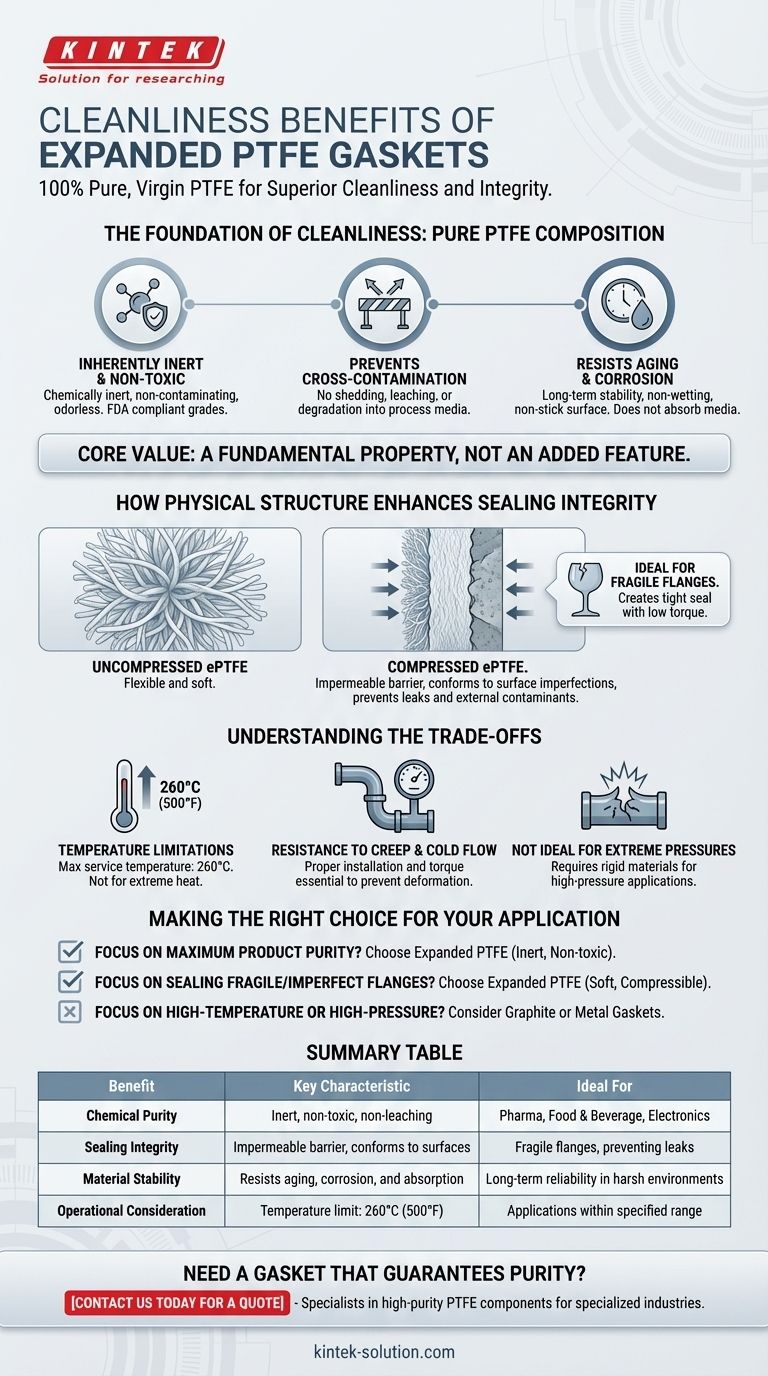

The Foundation of Cleanliness: Pure PTFE Composition

The value of expanded PTFE (ePTFE) in sensitive applications begins with its molecular makeup. Unlike blended materials, its properties are consistent and predictable.

Inherently Inert and Non-Toxic

Expanded PTFE is made from a single, pure material. It is one of the most chemically inert substances known, meaning it will not react with or degrade when exposed to even the most aggressive chemicals.

Because of this purity, ePTFE gaskets are inherently non-toxic, non-contaminating, and odorless. This makes them an ideal choice for industries like pharmaceuticals, food and beverage, and electronics, with many grades being fully compliant with FDA regulations.

Prevents Cross-Contamination

The inert nature of ePTFE ensures it will not shed particles or leach chemicals into the process fluid. This is critical for protecting the purity of the medium and preventing contamination that could ruin a high-value batch.

Resists Aging and Corrosion

PTFE does not age or degrade over time from exposure to chemicals or the environment. It will not corrode, and its non-wetting, non-stick surface means it does not absorb process media, further ensuring a clean and reliable sealing surface.

How Physical Structure Enhances Sealing Integrity

Beyond its chemical purity, the unique physical structure of ePTFE plays a direct role in maintaining a clean system by creating a superior seal.

An Impermeable Microstructure

Expanded PTFE is composed of a fine, multi-directional fiber structure. When the gasket is uncompressed, this structure provides excellent flexibility.

Upon compression, these fibers interlock to form a solid, impermeable barrier. This dense structure prevents leaks of the process media out into the environment and, just as importantly, prevents contaminants from the environment from entering the system.

Conforms to Surface Imperfections

The softness and high compressibility of ePTFE allow it to conform perfectly to flange surfaces, even those with minor scratches, pitting, or irregularities.

By filling these imperfections, the gasket creates an exceptionally tight seal. This is particularly valuable for protecting fragile equipment, such as glass-lined or plastic flanges, where applying high torque to create a seal is not an option.

Understanding the Trade-offs

While ePTFE offers exceptional cleanliness and conformability, it's crucial to understand its operational limits to ensure its proper application.

Temperature Limitations

Expanded PTFE has a broad service temperature range, from cryogenic levels up to approximately 260°C (500°F). Beyond this temperature, the material's integrity can be compromised. For higher-temperature applications, materials like graphite must be considered.

Resistance to Creep and Cold Flow

Expanded PTFE offers excellent resistance to creep and cold flow, which is the tendency of a material to deform under sustained pressure. However, it is still a soft material. Proper installation and torque procedures are essential to maintain a long-lasting seal, especially in cycling conditions.

Not Ideal for Extreme Pressures

The same softness that makes ePTFE ideal for delicate flanges makes it less suitable for extremely high-pressure applications. In such cases, a more rigid gasket material, often incorporating metal, is required to prevent blowout.

Making the Right Choice for Your Application

Selecting the correct gasket requires matching the material's strengths to your primary operational goal.

- If your primary focus is maximum product purity: Expanded PTFE is an industry-leading choice due to its inert, non-toxic, and non-contaminating properties.

- If your primary focus is sealing fragile or imperfect flanges: The exceptional softness and compressibility of ePTFE allow you to create a tight, reliable seal without risking damage to your equipment.

- If your primary focus is high-temperature or high-pressure service: You must evaluate materials beyond ePTFE, such as graphite or metal gaskets, that are specifically engineered for those demanding conditions.

Ultimately, choosing expanded PTFE is a decision to prioritize purity and adaptability in your sealing applications.

Summary Table:

| Benefit | Key Characteristic | Ideal For |

|---|---|---|

| Chemical Purity | Inert, non-toxic, non-leaching | Pharma, Food & Beverage, Electronics |

| Sealing Integrity | Impermeable barrier, conforms to surfaces | Fragile flanges, preventing leaks |

| Material Stability | Resists aging, corrosion, and absorption | Long-term reliability in harsh environments |

| Operational Consideration | Temperature limit: 260°C (500°F) | Applications within the specified range |

Need a gasket that guarantees purity?

At KINTEK, we specialize in manufacturing high-purity PTFE components, including seals and gaskets, for the semiconductor, medical, laboratory, and other specialized industries. Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get a sealing solution that protects your product integrity and process efficiency.

Contact us today to discuss your specific application requirements and receive a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining