In short, the primary benefits of using PTFE-faced thrust bearings in hydrogenerators are significantly increased operational efficiency, enhanced reliability during critical events, and the potential for a more compact and cost-effective machine design. These advantages stem directly from PTFE's unique material properties, which outperform traditional bearing materials in several key areas.

The core advantage is not just a single feature, but how PTFE's high load capacity and low friction fundamentally improve the performance and resilience of the entire hydrogenerator system, especially under demanding conditions.

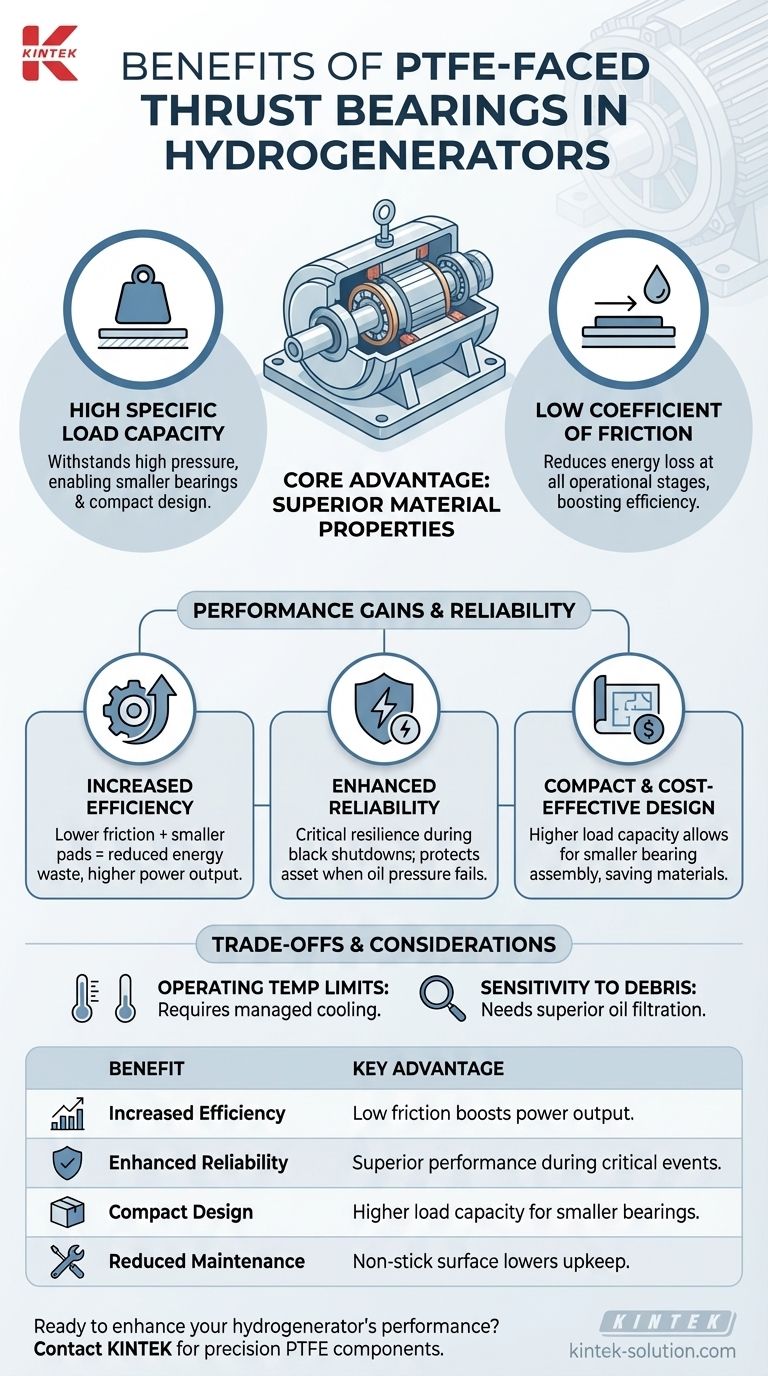

The Core Advantage: Superior Material Properties

To understand the benefits, we must first look at the material itself. PTFE (Polytetrafluoroethylene) offers a combination of properties that make it exceptionally well-suited for the high-stress environment of a hydrogenerator thrust bearing.

High Specific Load Capacity

PTFE can withstand extremely high pressures without failing. This tolerance for high specific loads is the foundational property that enables many of the other design benefits.

Traditional bearing materials, like babbitt, have lower pressure limits, requiring a larger surface area to support the same generator rotor weight.

Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material. This "non-stick" characteristic is critical for reducing energy losses, both when the machine is running and during the critical moments of startup and shutdown.

Translating Properties into Performance Gains

These material properties are not just academic; they translate directly into tangible improvements in hydrogenerator performance and cost.

Increased Generator Efficiency

The combination of a low-friction surface and the ability to use smaller thrust pads directly reduces rotational energy losses. Less energy is wasted as heat, meaning more of the water's power is converted into electricity, boosting the overall unit efficiency.

More Compact and Cost-Effective Design

Because PTFE can handle higher pressures, the thrust bearing pads can be made significantly smaller to support the same load. This reduces the overall size of the thrust bearing assembly, saving on material costs and potentially simplifying the generator's design.

Enhancing Operational Reliability

Beyond efficiency, PTFE provides a critical margin of safety and durability that protects the multi-million dollar asset.

Resilience During Critical Events

PTFE's low-friction nature makes it ideal for handling severe but occasional duties. A prime example is a "black shutdown" during a power failure, where lubricating oil pressure may be lost while the unit is still spinning down.

Under these conditions, a PTFE bearing is far less likely to seize or suffer catastrophic damage compared to a traditional bearing, preventing major repairs.

Reduced Maintenance Needs

The non-stick surface of PTFE resists the buildup of deposits or varnish from the lubricating oil. This cleanliness helps maintain a consistent oil film, reduces wear, and lowers the frequency of required maintenance and inspection.

Understanding the Trade-offs

As a technical advisor, it's my responsibility to provide a balanced view. While highly beneficial, PTFE bearings are not without their own engineering considerations.

Operating Temperature Limits

PTFE has a lower maximum operating temperature compared to metallic bearing materials. The generator's cooling and lubrication systems must be designed and maintained to ensure temperatures remain within the specified limits for the PTFE pad.

Sensitivity to Debris

While durable, the polymer surface can be more susceptible to damage from hard, sharp contaminants in the lubricating oil than a traditional babbitt bearing. Superior oil filtration and system cleanliness are therefore paramount.

Making the Right Choice for Your Goal

The decision to use PTFE-faced bearings should be aligned with your specific operational priorities.

- If your primary focus is maximizing operational efficiency: The reduced frictional losses from smaller, PTFE-faced pads provide a direct and measurable increase in power output.

- If your primary focus is reliability and grid stability: The bearing's ability to safely manage unlubricated coast-down events provides a critical layer of asset protection.

- If your primary focus is a new build or modernization: The design flexibility offered by smaller components can lead to a more compact, simpler, and cost-effective overall generator architecture.

Ultimately, adopting PTFE-faced thrust bearings allows for the design of more robust, efficient, and reliable hydrogenerators.

Summary Table:

| Benefit | Key Advantage |

|---|---|

| Increased Efficiency | Low friction reduces energy loss, boosting power output. |

| Enhanced Reliability | Superior performance during critical events like black shutdowns. |

| Compact Design | Higher load capacity allows for smaller, cost-effective bearings. |

| Reduced Maintenance | Non-stick surface resists deposits, lowering upkeep needs. |

Ready to enhance your hydrogenerator's performance with precision PTFE components?

At KINTEK, we specialize in the custom fabrication of high-performance PTFE seals, liners, and labware for the most demanding industrial applications, including the energy sector. Our expertise in precision production ensures your components meet the exact specifications required for superior efficiency and reliability, from prototypes to high-volume orders.

Contact us today to discuss how our PTFE solutions can benefit your next project: Get in touch

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the key benefits of PTFE extruded rods and glass-filled PTFE rods? Choose the Right High-Performance Polymer

- What are the primary functions of Teflon bushings? Achieve Maintenance-Free, Low-Friction Performance

- What may be required to help PTFE seals dissipate heat more quickly? Use Conductive Fillers for High-Temp Reliability

- How is Teflon sheet used in the manufacturing of electronic components? A Guide to High-Performance Insulation

- What are the key properties of PTFE/Teflon? Why It's the Ideal Choice for Demanding Machined Parts

- What is a floating ball valve and how does it seal line pressure? A Guide to Pressure-Actuated Sealing

- What industries benefit from using PTFE plugs? Solve Extreme Sealing Challenges

- What are the properties of Modified Polytetrafluoroethylene? Enhanced Performance for Demanding Applications