At their core, silicone/PTFE liners are designed to provide the best of two different materials in a single component. They combine the superior chemical inertness and non-stick properties of Polytetrafluoroethylene (PTFE) with the exceptional flexibility, resilience, and sealing capability of silicone. This dual-layer system ensures your sample is protected by an inert barrier while the container is secured with a highly reliable, airtight seal.

The central advantage isn't just a list of features, but a single, powerful concept: the PTFE layer protects the sample from the seal, while the silicone layer protects the sample from the outside world. This creates an unparalleled system for ensuring sample integrity.

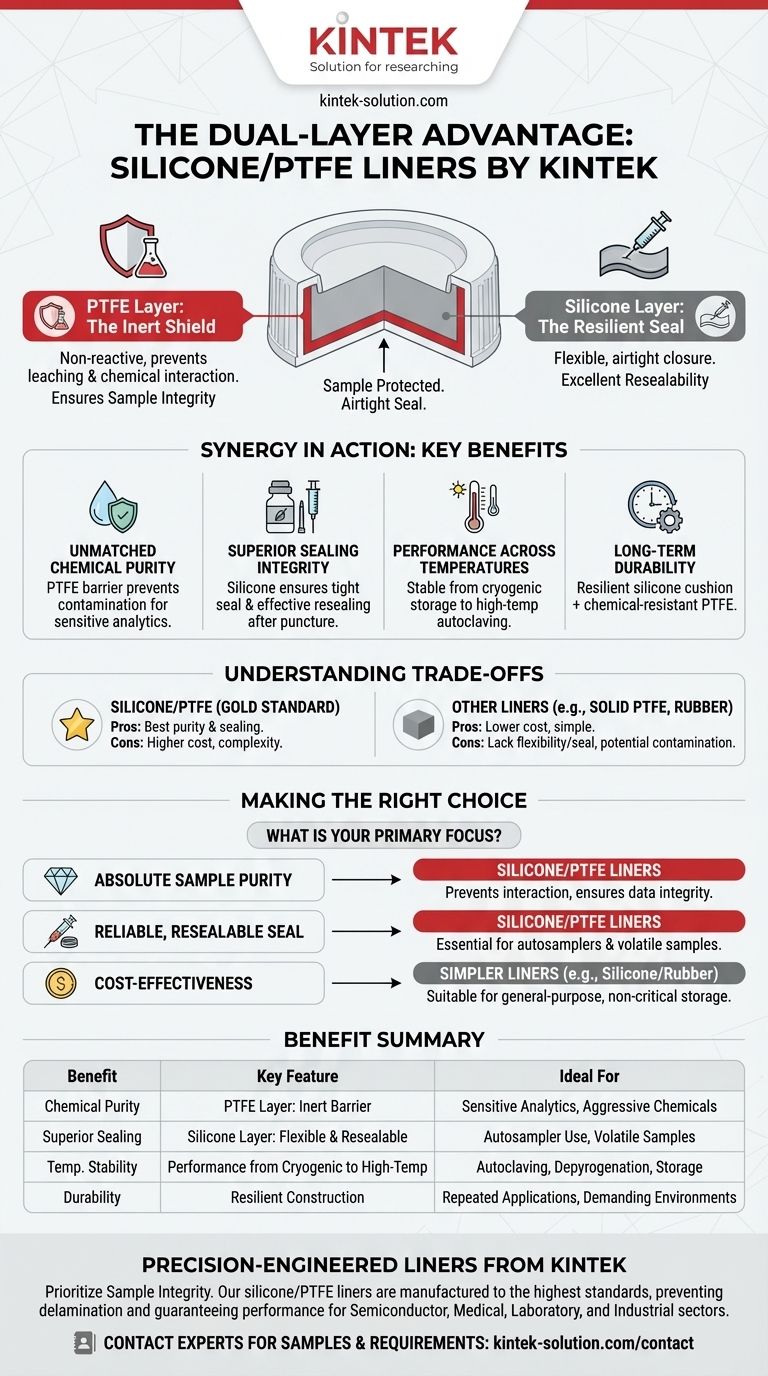

The Two-Material System: Why Both Silicone and PTFE?

To understand the benefits, you must first understand the distinct role each material plays. The liner is not a simple blend; it is a laminate where each layer performs a specific, critical function.

The PTFE Layer: The Inert Shield

The thin PTFE film is the layer that faces inward, making direct contact with the contents of the vial or container. Its primary job is to be completely non-reactive.

This is due to the incredibly strong carbon-fluorine bonds that define PTFE, making it one of the most non-reactive substances known. This means it will not leach chemicals into your sample or react with even highly aggressive solvents. Its low coefficient of friction also provides a non-stick surface, ensuring easy and complete sample retrieval.

The Silicone Layer: The Resilient Seal

The much thicker silicone layer forms the body of the liner. Its primary job is to create a perfect seal against the rim of the container.

Silicone is highly flexible and elastic, allowing it to conform perfectly to minor imperfections in the glass or plastic, creating an airtight closure. It maintains this flexibility across a wide range of temperatures and provides excellent resealability, making it ideal for applications requiring multiple punctures, such as with an autosampler.

Key Benefits in Practice

The synergy between these two materials translates into tangible advantages in demanding laboratory and industrial environments.

Unmatched Chemical Purity

The inert PTFE contact layer is the ultimate guarantee against sample contamination. It prevents the silicone from interacting with the sample, which is crucial when working with sensitive analytics, aggressive chemicals, or long-term storage where leaching could otherwise occur.

Superior Sealing Integrity

The silicone's flexibility ensures a tight, secure seal that prevents sample evaporation and protects against atmospheric contamination. After being pierced by a needle, the silicone's elasticity allows it to reseal effectively, maintaining the integrity of the remaining sample for subsequent analysis.

Performance Across Extreme Temperatures

Both silicone and PTFE are stable across a broad temperature spectrum. This makes the composite liners suitable for a wide variety of applications, from high-temperature autoclaving and depyrogenation to long-term cryogenic storage.

Long-Term Durability

The combination offers exceptional resilience. The silicone provides a durable, physical cushion, while the PTFE layer resists chemical degradation. This ensures the liner maintains its integrity over time, even with repeated use.

Understanding the Trade-offs

While silicone/PTFE liners are the gold standard for high-performance applications, they are not the only option. Understanding their limitations is key to making an informed choice.

Cost Consideration

The primary trade-off is cost. Manufacturing a bonded, dual-layer liner is more complex and expensive than producing a single-material liner from red rubber or even plain silicone. For less critical applications where sample inertness is not a primary concern, a more basic liner may be sufficient.

Comparison to Solid PTFE

A solid PTFE liner would offer maximum chemical inertness but lacks flexibility. A rigid PTFE disc cannot create the high-quality, conforming seal that the silicone layer provides, making it more susceptible to leaks, especially if the container rim is not perfectly flat.

Potential for Delamination

In very rare cases with lower-quality liners, the bond between the PTFE and silicone layers can fail. This can compromise the seal and expose the sample to the silicone, defeating the purpose of the liner. Sourcing from reputable manufacturers is critical to avoid this.

Making the Right Choice for Your Application

Selecting the correct liner is an investment in the quality and reliability of your results. Your choice should be dictated by the specific demands of your work.

- If your primary focus is absolute sample purity and preventing chemical interaction: The inert PTFE contact layer makes silicone/PTFE liners the only logical choice.

- If your primary focus is a reliable, resealable seal for volatile samples or autosampler use: The flexible and resilient silicone backing is essential for preventing leaks and maintaining integrity after puncture.

- If your primary focus is cost-effectiveness for general-purpose storage of non-reactive substances: A simpler, single-material liner like plain silicone or red rubber may be an acceptable alternative.

Ultimately, choosing a silicone/PTFE liner is a decision to prioritize data integrity and sample security above all else.

Summary Table:

| Benefit | Key Feature | Ideal For |

|---|---|---|

| Chemical Purity | PTFE layer prevents sample contamination | Sensitive analytics, aggressive chemicals |

| Superior Sealing | Silicone ensures airtight, resealable closure | Autosampler use, volatile samples |

| Temperature Stability | Performance from cryogenic to high-temperature | Autoclaving, depyrogenation, storage |

| Durability | Resilient construction for long-term use | Repeated applications, demanding environments |

Protect your most critical samples with precision-engineered liners from KINTEK.

Our silicone/PTFE liners are manufactured to the highest standards, ensuring the perfect bond between layers to prevent delamination and guarantee performance. Whether you need prototypes or high-volume orders for the semiconductor, medical, laboratory, or industrial sectors, KINTEK delivers components that prioritize your sample's integrity.

Contact our experts today to discuss your specific requirements and request samples.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How do Teflon membranes contribute to the accuracy and reliability of laboratory experiments? Ensure Purity and Precision

- What are the chemical compatibility differences between PTFE and silicone septa? Ensure Sample Integrity

- What is PTFE and how is it used in vial caps? Ensure Sample Purity with Inert Liner Technology

- Why is PTFE considered an essential material for laboratory applications? Unmatched Chemical Inertness & Thermal Stability

- Why are PTFE lined vials considered durable? Superior Chemical & Thermal Resistance for Reliable Performance

- What is the advantage of using PTFE ferromagnetic support discs? Achieve Flawless, Efficient Sample Preparation

- Is the PTFE bottle suitable for ultra-pure applications? Ensure Absolute Sample Integrity

- What are the safety features of PTFE-lined bottle caps? Ensure Chemical Inertness and Sample Integrity