The primary advantages of Teflon-lined valves stem from their unique composite design, which combines the structural strength of a metal body with the superior properties of a fluoropolymer lining. This grants them exceptional chemical inertness, high-temperature stability, and an extremely low-friction surface, making them ideal for controlling highly corrosive or pure media.

By isolating the process fluid from the metal valve body, a Teflon-lined valve offers the performance of an expensive exotic alloy valve at a significantly lower cost, providing a robust solution for the most demanding industrial applications.

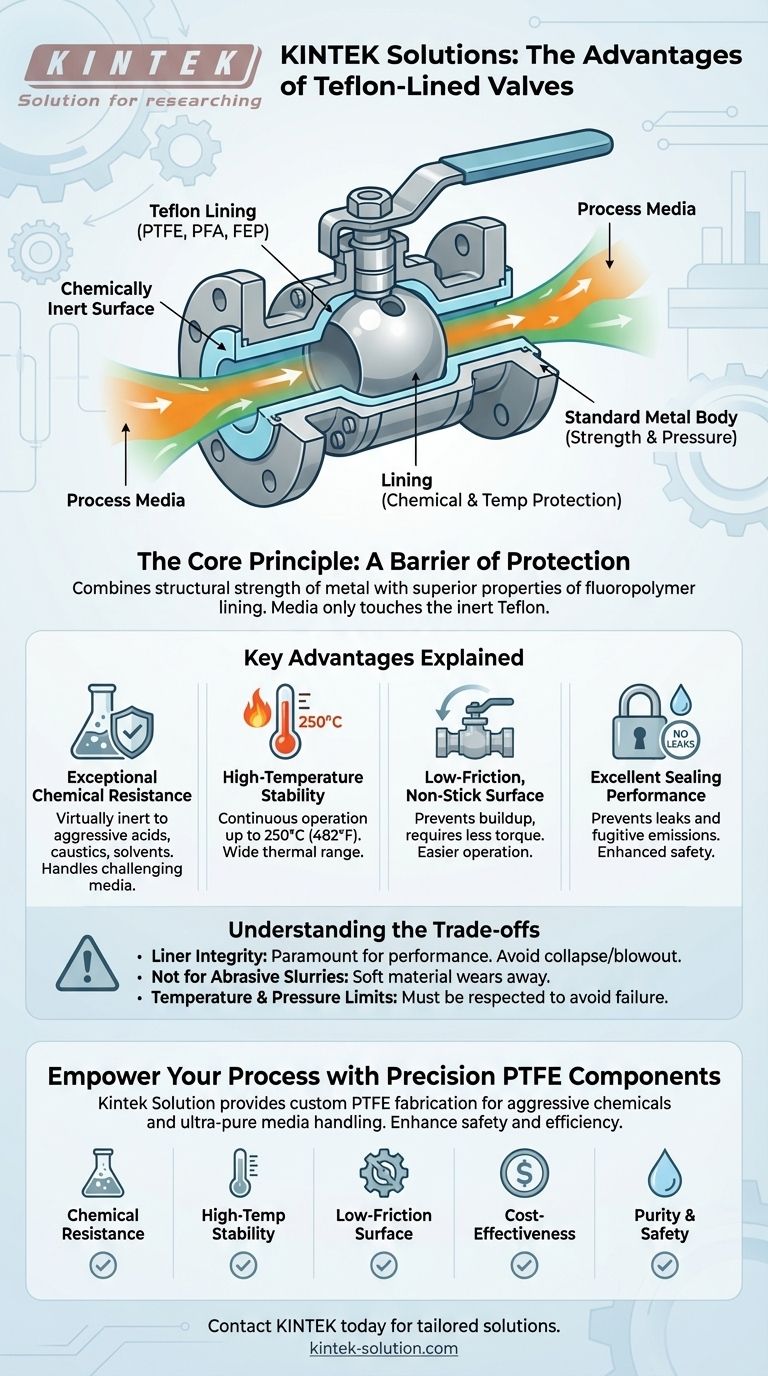

The Core Principle: A Barrier of Protection

A Teflon-lined valve isn't made entirely of Teflon (PTFE, PFA, or FEP). Instead, it uses a thick lining of this high-performance polymer molded to the interior surfaces of a standard cast iron, ductile iron, or steel valve body.

How the Lining Works

All parts that come into contact with the fluid—the valve body, ball, disc, and stem—are completely encapsulated by the liner. This design means the process media only ever touches the chemically inert Teflon, never the structural metal.

Strength Meets Resistance

This approach provides the best of both worlds. The outer metal body delivers the mechanical strength required to handle high line pressures and external impacts, while the inner lining provides elite protection against chemical attack and product contamination.

Key Advantages Explained

The unique properties of the Teflon lining are what deliver the valve's primary benefits, making it a go-to choice in industries from chemical processing to pharmaceuticals.

Exceptional Chemical Resistance

Teflon is virtually inert to almost all industrial chemicals and solvents. This makes these valves ideal for handling aggressive substances like strong acids, caustics, and chlorinated compounds that would quickly destroy standard metal valves.

High-Temperature Stability

Fluoropolymer linings can operate continuously at high temperatures, often up to 250°C (482°F) or higher, depending on the specific polymer grade. This allows them to be used in a wide range of thermal applications without degradation.

Low-Friction, Non-Stick Surface

Teflon has one of the lowest coefficients of friction of any solid material. This non-stick quality prevents media from building up on valve internals, which is critical for purity. It also means the valve requires less torque to open and close, allowing for smaller, less expensive actuators and easier manual operation.

Excellent Sealing Performance

The inherent properties of the liner material, combined with robust valve design, provide superior sealing. This prevents leaks, enhances plant safety, and eliminates fugitive emissions, which is critical for handling hazardous materials.

Understanding the Trade-offs

While highly effective, it's important to recognize the design limitations of lined valves to ensure proper application and long-term reliability.

Liner Integrity is Paramount

The entire performance of the valve depends on the integrity of the liner. High-quality valves feature linings that are locked into the metal body to prevent liner collapse under vacuum or blowout under high pressure. A compromised liner means immediate valve failure.

Not for Abrasive Slurries

While durable, Teflon is a relatively soft material. These valves are generally not suited for services with significant abrasive particles or slurries, as this can physically wear away the liner and lead to premature failure.

Temperature and Pressure Limits

Every lined valve has a specific temperature and pressure rating that must be respected. Exceeding these limits can compromise the liner's mechanical properties and its bond to the valve body, leading to catastrophic failure.

Making the Right Choice for Your Goal

Selecting a Teflon-lined valve is a strategic decision based on your specific operational needs.

- If your primary focus is handling aggressive chemicals: A lined valve provides a cost-effective alternative to valves made from expensive Hastelloy or other exotic alloys.

- If your primary focus is product purity (pharma/food): The non-stick, inert surface prevents contamination and material buildup, ensuring the integrity of the final product.

- If your primary focus is long-term reliability and low maintenance: The durability of the liner reduces the need for frequent valve replacement, leading to significant cost savings over the valve's lifespan.

Ultimately, Teflon-lined valves empower you to manage challenging process fluids with confidence, safety, and efficiency.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Chemical Resistance | Handles strong acids, caustics, and solvents |

| High-Temperature Stability | Operates continuously up to 250°C (482°F) |

| Low-Friction Surface | Prevents media buildup, requires less operating torque |

| Cost-Effectiveness | Performance of exotic alloys at a lower cost |

| Purity & Safety | Inert surface prevents contamination, superior sealing |

Empower your process with precision-engineered PTFE components from KINTEK.

Are you managing aggressive chemicals or requiring ultra-pure media handling in the semiconductor, medical, laboratory, or industrial sectors? Our expertise in custom PTFE fabrication—from prototypes to high-volume orders—ensures you get the exact Teflon-lined valves, seals, liners, and labware your application demands.

We prioritize precision production to deliver components that offer superior chemical resistance, temperature stability, and reliability, enhancing your operational safety and efficiency.

Contact KINTEK today to discuss your specific requirements and discover how our tailored PTFE solutions can solve your most challenging fluid control problems.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the primary materials used for oil seals? NBR vs. PTFE for Your Application

- How does a PTFE lined dual plate check valve operate? Prevent Backflow in Corrosive & High-Purity Systems

- What are the main technical parameters for calculating PTFE rubber bearing pads? Ensure Structural Integrity & Movement

- What precautions should be taken when handling PTFE gaskets? Ensure Longevity & Performance

- What future advancements are expected for PTFE oil seals? From Smart Seals to 3D Printing

- What are the key advantages of using PTFE in sealing applications? Superior Performance in Extreme Conditions

- What makes PTFE coatings non-stick? The Science Behind the Ultimate Slippery Surface

- What are the limitations of PTFE bellows? Understanding Its Mechanical and Chemical Boundaries