At its core, Polytetrafluoroethylene (PTFE) is one of the most versatile gasket materials available. Its primary advantages stem from an extreme chemical resistance that makes it nearly inert, an exceptionally wide operating temperature range, and inherent non-stick properties. This unique combination allows PTFE gaskets to provide a reliable seal in demanding industrial, chemical, and sanitary applications where other materials would quickly fail.

The decision to use a PTFE gasket is a decision for resilience. While its performance in extreme chemical and thermal environments is unmatched, understanding its primary mechanical limitation—the tendency to "creep" under load—is critical for ensuring a long-term, leak-free seal.

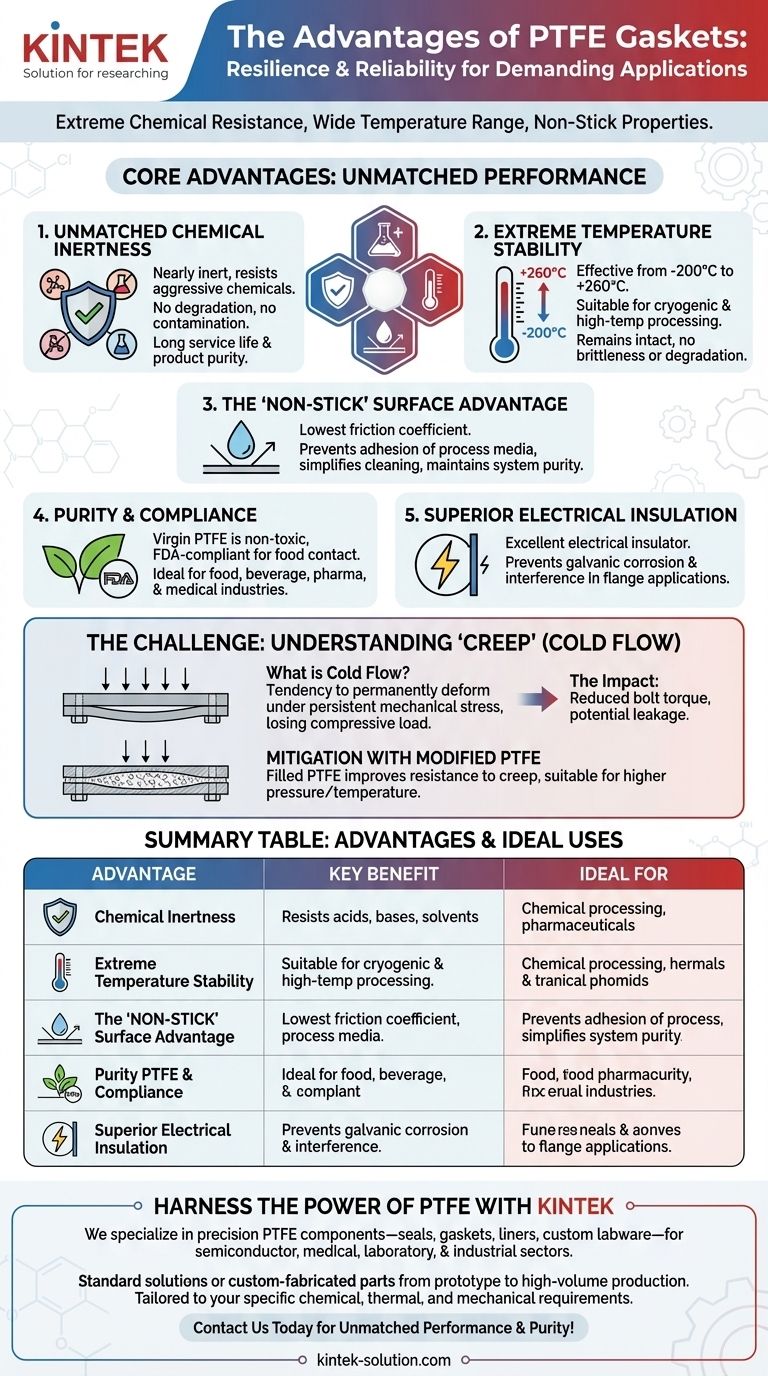

Deconstructing the Core Advantages of PTFE

To understand if PTFE is the right choice for your application, it's essential to look beyond a simple feature list and analyze the practical impact of each core property.

Unmatched Chemical Inertness

A key benefit of PTFE is its near-total immunity to chemical attack. It reliably resists the most aggressive acids, bases, solvents, and chemicals.

This inertness is critical for two reasons. First, the gasket itself will not degrade or corrode, ensuring a long service life. Second, it prevents the gasket from leaching contaminants into the process media, protecting the purity of the final product.

Extreme Temperature Stability

PTFE gaskets operate effectively across an exceptionally broad temperature spectrum, typically from -200°C to +260°C (-328°F to +500°F).

This makes it one of the few materials suitable for both cryogenic applications and high-temperature processing. Its stability ensures the seal remains intact without becoming brittle at low temperatures or degrading at high temperatures.

The 'Non-Stick' Surface Advantage

PTFE has one of the lowest coefficients of friction of any solid material, giving it a slippery, non-stick surface.

This property prevents process media from adhering to the gasket surface, which simplifies cleaning, reduces material buildup, and helps maintain a pure, uncontaminated system. This is particularly valuable in applications with viscous or sticky fluids.

Purity and Compliance for Sensitive Industries

Virgin PTFE is inherently non-toxic and can comply with FDA regulations for food-contact materials.

This makes it a standard choice in food and beverage processing, pharmaceutical manufacturing, and medical device industries where preventing contamination and ensuring consumer safety are paramount.

Superior Electrical Insulation

Beyond its sealing capabilities, PTFE is an excellent electrical insulator. This property makes it valuable in applications where a flange must be electrically isolated to prevent galvanic corrosion or interference.

Understanding the Trade-offs: The Challenge of Creep

No material is perfect. To use PTFE effectively, you must understand its primary mechanical weakness: creep, also known as cold flow.

What is Cold Flow (Creep)?

Creep is the tendency of a solid material to deform permanently under the influence of persistent mechanical stress. For a gasket, this means the material slowly "flows" or squeezes out from between the flanges over time.

This phenomenon is accelerated by higher temperatures and pressure, even within PTFE's acceptable operating range.

The Practical Impact on Sealing

The direct consequence of creep is a loss of compressive load on the gasket. This reduces the bolt torque that holds the flange together, which can eventually compromise the seal and lead to leakage.

Because of this, standard PTFE is not always the best choice for high-pressure applications or those that experience significant temperature cycling without specialized design considerations.

Mitigating Creep with Modified PTFE

This known limitation has led to the development of modified PTFE materials. By adding fillers like glass, graphite, or silica, manufacturers create "filled PTFE" gaskets.

These fillers provide structural reinforcement, drastically improving the material's resistance to creep and making it suitable for more demanding high-pressure and high-temperature service.

Making the Right Choice for Your Application

Selecting the correct gasket requires matching the material's properties to the primary demands of your system.

- If your primary focus is chemical purity or FDA compliance: Virgin PTFE is the definitive choice for applications in food, beverage, and pharmaceutical industries where inertness is the top priority.

- If your primary focus is sealing high-pressure or high-temperature systems: A filled or expanded PTFE (ePTFE) gasket is necessary to resist creep and maintain a reliable, long-term seal under demanding mechanical loads.

- If your primary focus is a general-purpose seal with moderate conditions: While PTFE will work, it may be over-specified; other materials like rubber or non-asbestos composites could offer a more economical solution.

Ultimately, harnessing the power of PTFE gaskets comes from understanding both their exceptional strengths and their inherent mechanical limitations.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Chemical Inertness | Resists aggressive acids, bases, and solvents | Chemical processing, pharmaceuticals |

| Temperature Stability | Operates from -200°C to +260°C | Cryogenic to high-temperature applications |

| Non-Stick Surface | Prevents material buildup, easy to clean | Viscous fluids, sanitary systems |

| Purity & Compliance | FDA compliant, non-toxic | Food, beverage, medical industries |

| Electrical Insulation | Prevents galvanic corrosion | Electrical isolation applications |

Ready to harness the power of PTFE gaskets for your application?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, gaskets, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need a standard solution or a custom-fabricated part from prototype to high-volume production, our expertise ensures a reliable, long-lasting seal tailored to your specific chemical, thermal, and mechanical requirements.

Contact us today to discuss your project and get a solution that delivers unmatched performance and purity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials