In the world of fluid control, the advantages of using Polytetrafluoroethylene (PTFE) for ball valve seats stem from its unique combination of properties. PTFE offers exceptional chemical resistance, an incredibly low coefficient of friction for smooth operation, and the necessary ductility to create a bubble-tight seal with minimal torque. This makes it a highly reliable and versatile default material for a vast range of applications.

The core reason for PTFE's dominance is its status as a high-performance generalist; it provides excellent chemical compatibility and sealing for most standard industrial conditions. However, true expertise lies in recognizing its specific temperature and pressure limitations, which determine when a more specialized material is required.

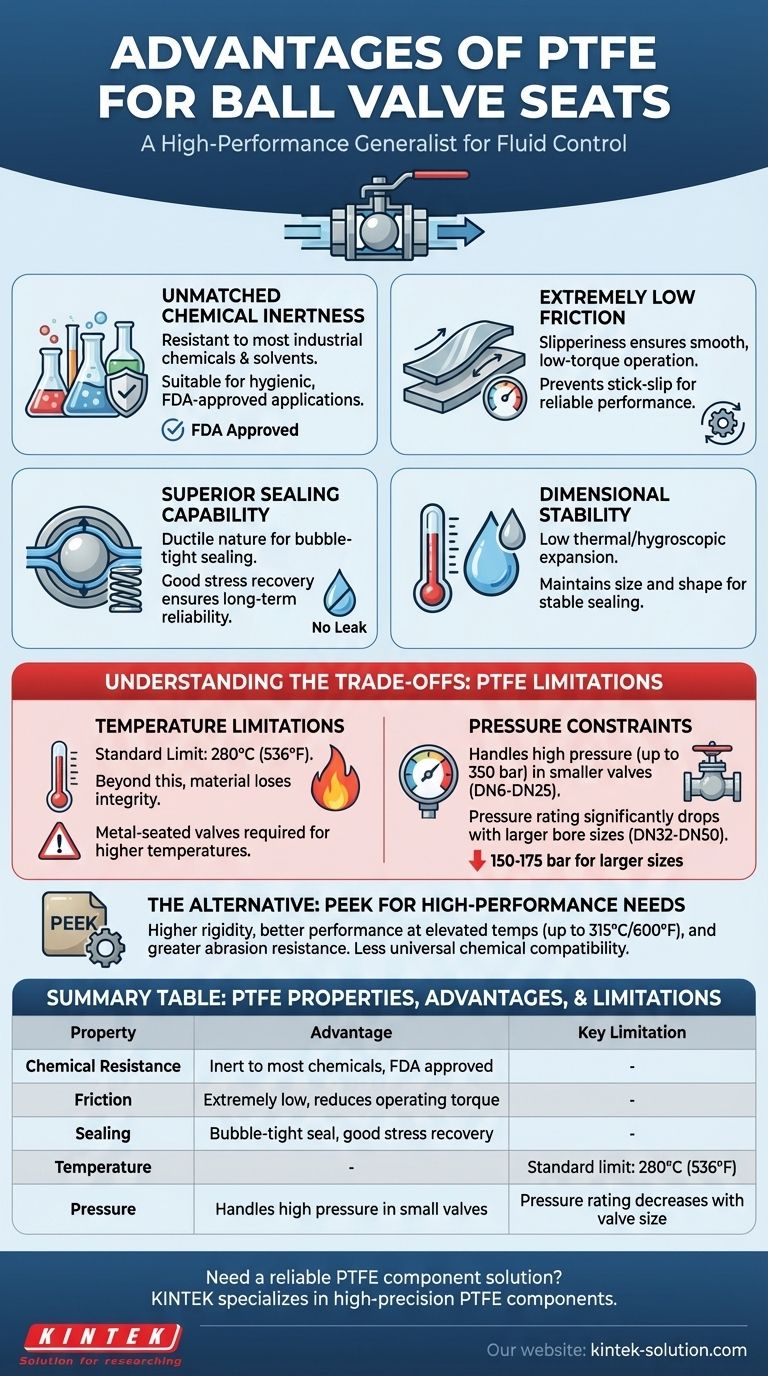

The Core Properties That Define PTFE Seats

The practical advantages of PTFE are a direct result of its fundamental material characteristics. Understanding these properties explains why it performs so well in its intended role.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals and solvents. This makes it the safest and most reliable choice for applications involving aggressive or corrosive media.

This property also makes PTFE seats suitable for hygienic applications, as they are non-contaminating, easy to clean, and often carry FDA approval.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "slipperiness" is critical for valve performance.

This characteristic means the valve can be opened and closed with very little torque, reducing the size and cost of actuators. It also allows the valve to operate smoothly without lubricants, preventing "stick-slip" behavior that can cause jerky movements.

Superior Sealing Capability

A valve seat's primary job is to seal, and PTFE's physical properties are ideal for this. It is ductile enough to deform slightly under pressure, conforming perfectly to the ball's surface to create a tight seal.

Furthermore, PTFE exhibits good stress recovery, meaning it can return to its original shape after being compressed, ensuring a reliable seal over many cycles.

Dimensional Stability

PTFE has very low thermal and hygroscopic (water absorption) expansion coefficients. This means the seat's size and shape remain stable across a range of temperatures and humidity levels, preventing leaks caused by material changes.

Understanding the Trade-offs: When PTFE Isn't the Right Choice

While PTFE is an excellent all-around material, its effectiveness is confined to specific operational boundaries. Pushing it beyond these limits will lead to premature failure.

Temperature Limitations

Standard PTFE is generally not recommended for service temperatures that consistently exceed 280°C (536°F). Beyond this point, the material loses its structural integrity.

For applications involving higher temperatures, metal-seated ball valves are the required solution, as no polymer can withstand those conditions.

Pressure Constraints

PTFE seats have clear pressure limitations that are directly related to the valve's size. For smaller valves (e.g., DN6-DN25), PTFE can handle pressures up to 350 bar (5,075 PSI).

However, for larger bore sizes (e.g., DN32-DN50), the maximum allowable pressure drops significantly to around 150-175 bar. Exceeding these limits can cause the seat to extrude or fail.

The Alternative: PEEK for High-Performance Needs

When an application's pressure, temperature, or abrasive nature exceeds PTFE's capabilities, Polyetheretherketone (PEEK) is a common alternative.

PEEK offers higher rigidity, better performance at elevated temperatures (up to 315°C or 600°F), and greater abrasion resistance. The trade-off is that it has less universal chemical compatibility than PTFE and is not suitable for use with certain corrosive acids.

Making the Right Choice for Your Application

Selecting the correct seat material is a critical engineering decision. Your choice should be guided by the specific demands of your system.

- If your primary focus is broad chemical compatibility and low cost: Virgin PTFE is the definitive choice for the vast majority of standard industrial and chemical applications.

- If you are dealing with high pressures or abrasive media: Consider a more robust material like filled PTFE or PEEK for its superior toughness and wear resistance.

- If your application involves temperatures consistently exceeding 280°C (536°F): PTFE is unsuitable, and you must specify a metal-seated ball valve for safe and reliable operation.

By understanding these material properties and their operational limits, you can select a valve seat that ensures both safety and long-term reliability.

Summary Table:

| Property | Advantage | Key Limitation |

|---|---|---|

| Chemical Resistance | Inert to most chemicals, FDA approved | - |

| Friction | Extremely low, reduces operating torque | - |

| Sealing | Bubble-tight seal, good stress recovery | - |

| Temperature | - | Standard limit: 280°C (536°F) |

| Pressure | Handles high pressure in small valves | Pressure rating decreases with valve size |

Need a reliable PTFE component solution?

KINTEK specializes in manufacturing high-precision PTFE components, including custom ball valve seats, seals, liners, and labware. We serve the semiconductor, medical, laboratory, and industrial sectors with custom fabrication from prototypes to high-volume orders.

Let us provide the precision and reliability your application demands. Contact our experts today to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability