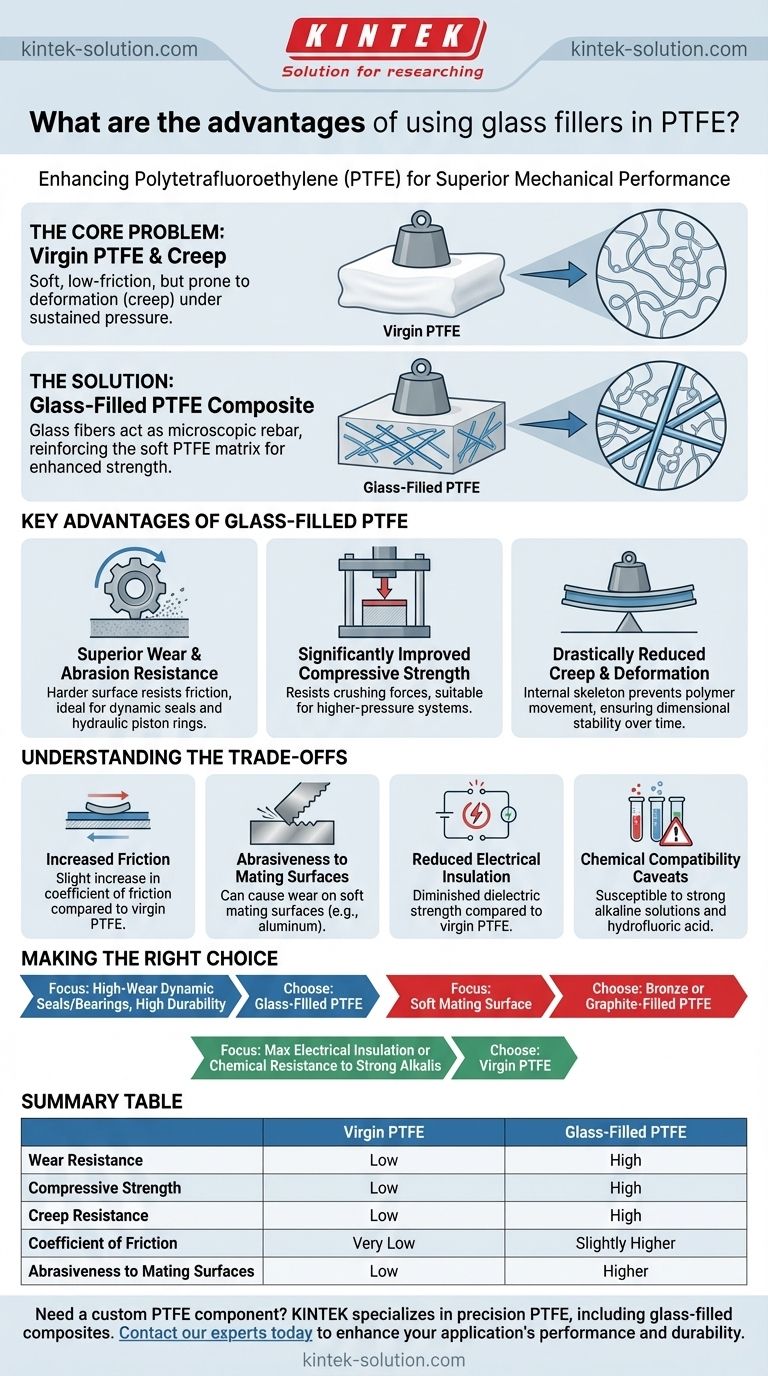

In short, adding glass fillers to Polytetrafluoroethylene (PTFE) fundamentally enhances its mechanical properties. This transforms the material from a soft, low-friction polymer into a durable, structural-grade composite with significantly improved strength, stiffness, and resistance to wear and deformation under load.

The core problem with pure, or "virgin," PTFE is its tendency to deform (creep) under sustained pressure. Glass fillers act like a microscopic rebar, reinforcing the soft PTFE matrix to create a much more robust material suitable for demanding mechanical applications.

Why Virgin PTFE Often Needs Reinforcement

Virgin PTFE is renowned for its extremely low coefficient of friction and chemical inertness. However, its mechanical properties present significant limitations in many engineering scenarios.

The Challenge of "Creep" or Cold Flow

Creep is the tendency of a solid material to deform permanently under the influence of persistent mechanical stress. Virgin PTFE is exceptionally prone to this, especially under compressive loads, limiting its use as a structural component.

Limitations in High-Load Applications

While its slipperiness is an asset, the inherent softness of PTFE means it can be easily misshapen or worn away in applications involving high pressure or significant abrasive forces, such as in dynamic seals or bearings.

The Core Advantages of Glass-Filled PTFE

Introducing glass fibers or powder into the PTFE matrix directly addresses these weaknesses, creating a material with a much broader range of uses.

Superior Wear and Abrasion Resistance

The addition of glass provides a harder, more durable surface. This drastically improves the material's ability to withstand friction and abrasive forces, making it a standard choice for components like hydraulic piston rings and seals.

Significantly Improved Compressive Strength

Glass-filled PTFE is far more resistant to crushing forces than its unfilled counterpart. The amount of glass filler is often directly proportional to the increase in compressive strength, allowing the material to be used in higher-pressure systems.

Drastically Reduced Creep and Deformation

The rigid glass fibers provide an internal skeleton within the PTFE. This reinforcement prevents the polymer chains from easily moving past one another, dramatically reducing the tendency to creep under a constant load and ensuring dimensional stability over time.

Understanding the Trade-offs

While glass fillers add immense value, they also alter some of virgin PTFE's fundamental properties. Understanding these trade-offs is critical for proper material selection.

Increased Coefficient of Friction

Adding any filler will slightly increase PTFE's coefficient of friction. You are trading the absolute lowest friction for a massive gain in durability and wear life.

Abrasiveness to Mating Surfaces

Glass is an abrasive material. In dynamic applications, glass-filled PTFE can cause accelerated wear on softer mating surfaces, such as aluminum or certain grades of stainless steel. This must be considered in the overall system design.

Reduced Electrical Insulation

Virgin PTFE is an outstanding electrical insulator. The addition of glass fillers diminishes these properties, making it less suitable for applications where high dielectric strength is the primary requirement.

Chemical Compatibility Caveats

While PTFE itself is nearly universally inert, glass is not. Glass-filled PTFE is susceptible to attack by strong alkaline solutions and hydrofluoric acid, environments where virgin PTFE would be unaffected.

Making the Right Choice for Your Application

Selecting the correct material depends entirely on the primary demands of your project.

- If your primary focus is high-wear dynamic seals or bearings: Glass-filled PTFE is an excellent choice, offering a superb balance of low friction and high durability.

- If your primary focus is preserving a soft mating surface: Consider a PTFE composite with a less abrasive filler, such as bronze or graphite.

- If your primary focus is maximum electrical insulation: Virgin PTFE is the only suitable option; all filled grades will compromise performance.

- If your primary focus is chemical resistance to strong alkalis: You must use virgin PTFE, as the glass filler will be chemically attacked.

By reinforcing PTFE with glass, you transform an excellent low-friction material into a high-performance engineering component for demanding applications.

Summary Table:

| Property | Virgin PTFE | Glass-Filled PTFE |

|---|---|---|

| Wear Resistance | Low | High |

| Compressive Strength | Low | High |

| Creep Resistance | Low | High |

| Coefficient of Friction | Very Low | Slightly Higher |

| Abrasiveness to Mating Surfaces | Low | Higher |

Need a custom PTFE component that balances low friction with high strength?

KINTEK specializes in manufacturing precision PTFE components, including glass-filled composites, for the semiconductor, medical, laboratory, and industrial sectors. We can help you select the right material and provide custom fabrication from prototypes to high-volume orders.

Contact our experts today to discuss how our reinforced PTFE solutions can enhance your application's performance and durability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the primary properties of Teflon that make it a 'powerhouse plastic'? Unlock Unmatched Performance

- What environmental factors is PTFE resistant to, contributing to its durability? Discover Its Unmatched Resistance

- What are the key properties of Polytetrafluoroethylene (PTFE)? Unlock Extreme Performance

- What are the key properties of bronze bushings? Achieve High-Load, Low-Maintenance Performance

- How does Teflon's friction coefficient benefit mechanical applications? Reduce Wear and Energy Consumption

- What is the operating temperature range for PTFE? Master the Limits for Your Application

- What are the advantages of using Teflon? Achieve Superior Performance in Extreme Conditions

- How does PTFE's coefficient of friction compare to other plastics? Unmatched Low-Friction Performance