The fundamental advantage of spring-energized PTFE seals is their ability to perform reliably under conditions that cause conventional elastomeric seals to fail. They are specifically engineered to overcome the limitations of elastomers when faced with chemical attack, extreme temperatures, high pressure, or demanding frictional requirements. This makes them a problem-solver for critical applications where seal failure is not an option.

While elastomeric seals are suitable for a wide range of general-purpose applications, spring-energized PTFE seals are a specialized solution. They provide unmatched reliability in extreme operating environments where elastomers would quickly degrade, deform, and ultimately fail.

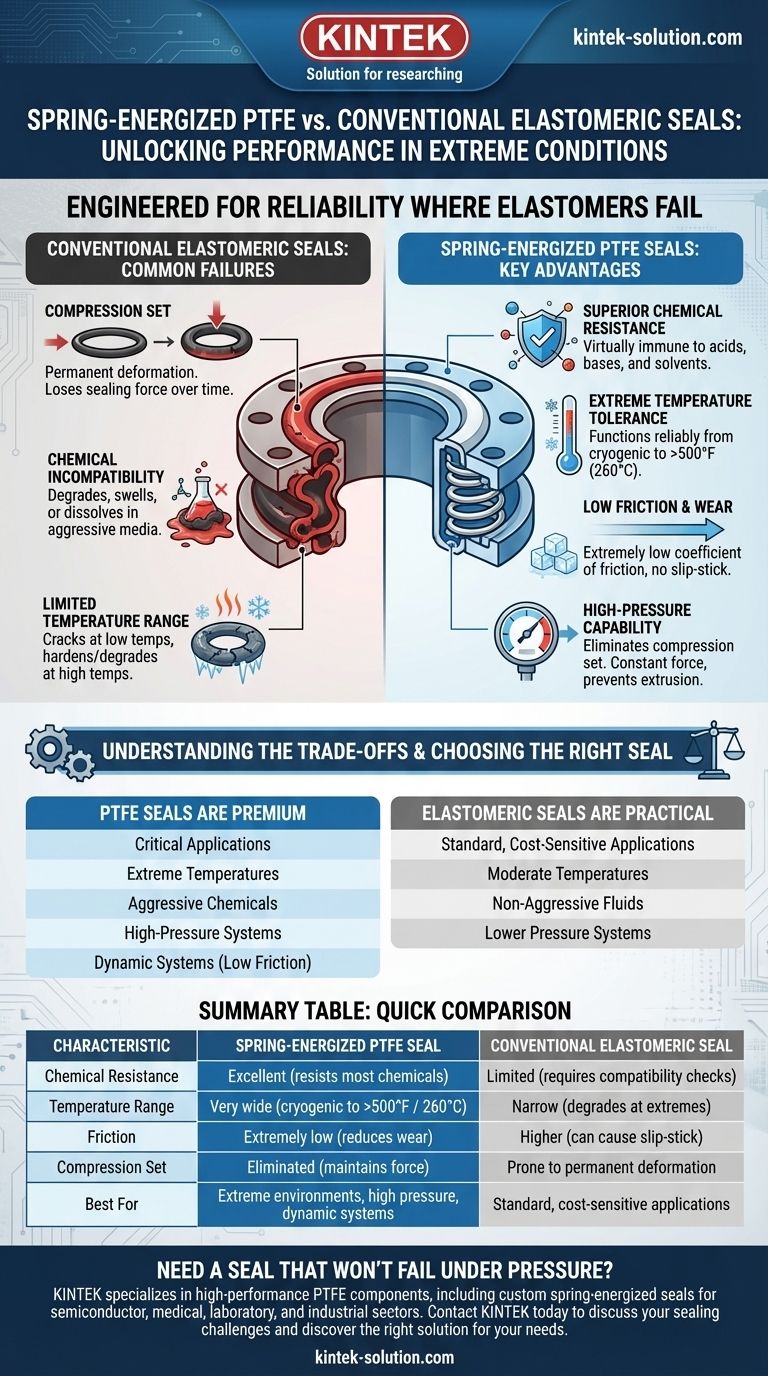

Why Elastomers Fail in Extreme Conditions

To understand the value of a PTFE seal, we must first understand the common failure points of a standard elastomeric O-ring or seal in demanding situations.

The Problem of Compression Set

Elastomers rely on their inherent elasticity—their ability to "bounce back"—to create a seal. Over time, especially under high temperatures and pressure, this elasticity degrades.

The material takes a permanent "set" and no longer pushes back against the sealing surfaces, creating a critical leak path. This is known as compression set.

Chemical Incompatibility

Many powerful acids, solvents, and corrosive fluids used in industries like chemical processing and pharmaceuticals can attack elastomeric seals.

This chemical attack can cause the seal to swell, shrink, or completely dissolve, leading to immediate seal failure. Compatibility checks are always required.

Limited Temperature Range

Conventional elastomers have a relatively narrow operating temperature window.

In cryogenic conditions, they become brittle and can crack. At high temperatures, they can harden, degrade, and lose their sealing ability rapidly.

Key Advantages of Spring-Energized PTFE Seals

A spring-energized seal uses a durable polymer jacket, typically made of PTFE, and a corrosion-resistant metal spring. The spring provides a constant, resilient force on the seal lips, creating a highly reliable barrier that overcomes the weaknesses of elastomers.

Superior Chemical Resistance

PTFE is one of the most chemically inert materials available.

This makes PTFE seals virtually immune to degradation from acids, bases, solvents, and other aggressive media. They eliminate the need for extensive fluid compatibility testing in critical applications.

Extreme Temperature Tolerance

Spring-energized PTFE seals function reliably across an exceptionally wide temperature range.

They maintain their integrity and sealing force in cryogenic conditions and at continuous operating temperatures exceeding 500°F (260°C), where an elastomer would be destroyed.

Low Friction and Wear

PTFE has an extremely low coefficient of friction, often compared to wet ice on wet ice.

This property reduces energy loss and heat generation in dynamic applications. It also prevents the "slip-stick" phenomenon—a jerky motion common with elastomers at low speeds—and often eliminates the need for lubrication.

High-Pressure Capability

The spring provides a consistent radial force that is independent of system pressure, ensuring a tight seal from low to very high pressures.

Crucially, the PTFE jacket and spring mechanism eliminate compression set. The seal will not deform permanently, guaranteeing long-term sealing performance and preventing extrusion under high pressure.

Understanding the Trade-offs

While highly effective, spring-energized PTFE seals are not a universal replacement for elastomers. Objectively choosing the right seal requires understanding their intended purpose.

The Critical Role of the Spring

The spring's design is key to the seal's performance.

Different spring geometries and load levels allow the seal to be customized. A heavy-load spring provides maximum sealing force where friction is a lower priority, while a light-load spring reduces friction and wear for high-speed dynamic systems.

When Elastomers Are a Better Fit

Spring-energized PTFE seals are a premium, engineered solution for demanding problems.

For standard, cost-sensitive applications without extreme temperatures, aggressive chemicals, or high pressures, a conventional elastomeric seal is often the more practical and cost-effective choice.

Design and Installation

PTFE jackets are significantly more rigid than elastomeric seals.

This means they are less forgiving of hardware imperfections and may require different gland designs or special installation tools to prevent damage to the seal lips during assembly.

Making the Right Choice for Your Application

Selecting the correct seal technology depends entirely on the operational demands and failure risks of your specific system.

- If your primary focus is sealing in extreme temperatures or with harsh chemicals: Spring-energized PTFE seals are the definitive choice for reliability where elastomers would degrade.

- If your primary focus is reducing friction in dynamic systems: The low-friction properties of PTFE seals improve efficiency, reduce wear, and eliminate slip-stick problems.

- If your primary focus is high-pressure sealing or avoiding compression set: The spring mechanism ensures a constant, reliable sealing force that prevents extrusion and permanent deformation.

- If your primary focus is a standard, cost-sensitive application: A conventional elastomeric seal is often the most practical and effective solution when extreme conditions are not a factor.

Ultimately, choosing the right seal is about matching the material's capabilities to the precise demands of your operating environment.

Summary Table:

| Characteristic | Spring-Energized PTFE Seal | Conventional Elastomeric Seal |

|---|---|---|

| Chemical Resistance | Excellent (resists acids, bases, solvents) | Limited (requires compatibility checks) |

| Temperature Range | Very wide (cryogenic to >500°F / 260°C) | Narrow (degrades at extremes) |

| Friction | Extremely low (reduces wear, no lubrication) | Higher (can cause slip-stick) |

| Compression Set | Eliminated (maintains sealing force) | Prone to permanent deformation |

| Best For | Extreme environments, high pressure, dynamic systems | Standard, cost-sensitive applications |

Need a seal that won't fail under pressure?

If your application involves extreme temperatures, aggressive chemicals, or high-pressure systems, a standard elastomer may not be enough. KINTEK specializes in manufacturing high-performance PTFE components, including custom spring-energized seals, for the semiconductor, medical, laboratory, and industrial sectors.

We provide:

- Superior Reliability: Seals engineered to perform where elastomers fail.

- Custom Fabrication: From prototypes to high-volume orders, tailored to your exact specifications.

- Precision Production: Ensuring optimal performance for your most critical applications.

Contact KINTEK today to discuss your sealing challenges and discover the right solution for your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What industries benefit from the use of PTFE rotary shaft seals? Enhance Reliability in Harsh Environments

- What are the advantages of using custom Teflon parts? Unlock Superior Performance in Demanding Applications

- What are the key features of fully lined ball valves? Engineered for Total Corrosion Resistance

- Why is it important to use high-quality PTFE packings in industrial processes? Ensure Safety and Maximize Uptime

- What raw material is used to manufacture PTFE spacers? Discover the Power of Teflon for High-Performance Components

- What is the biggest advantage of Teflon washers? Achieve Self-Lubricating, Low-Friction Performance

- What are common mistakes to avoid when using PTFE gaskets? Prevent Costly Leaks and Downtime

- What is the purpose of dimples on the PTFE surface of these bearings? Enhancing Lubrication and Longevity