In short, PTFE diaphragms are chosen for their exceptional resistance to aggressive chemicals and extreme temperatures. Their unique molecular structure gives them a combination of chemical inertness, thermal stability, and mechanical durability that few other materials can match, making them a default choice for demanding industrial applications.

The core advantage of a PTFE diaphragm is not just one property, but its unique fusion of capabilities. It provides an extremely reliable and long-lasting barrier in environments where other materials would quickly degrade, ensuring operational safety and minimizing costly downtime.

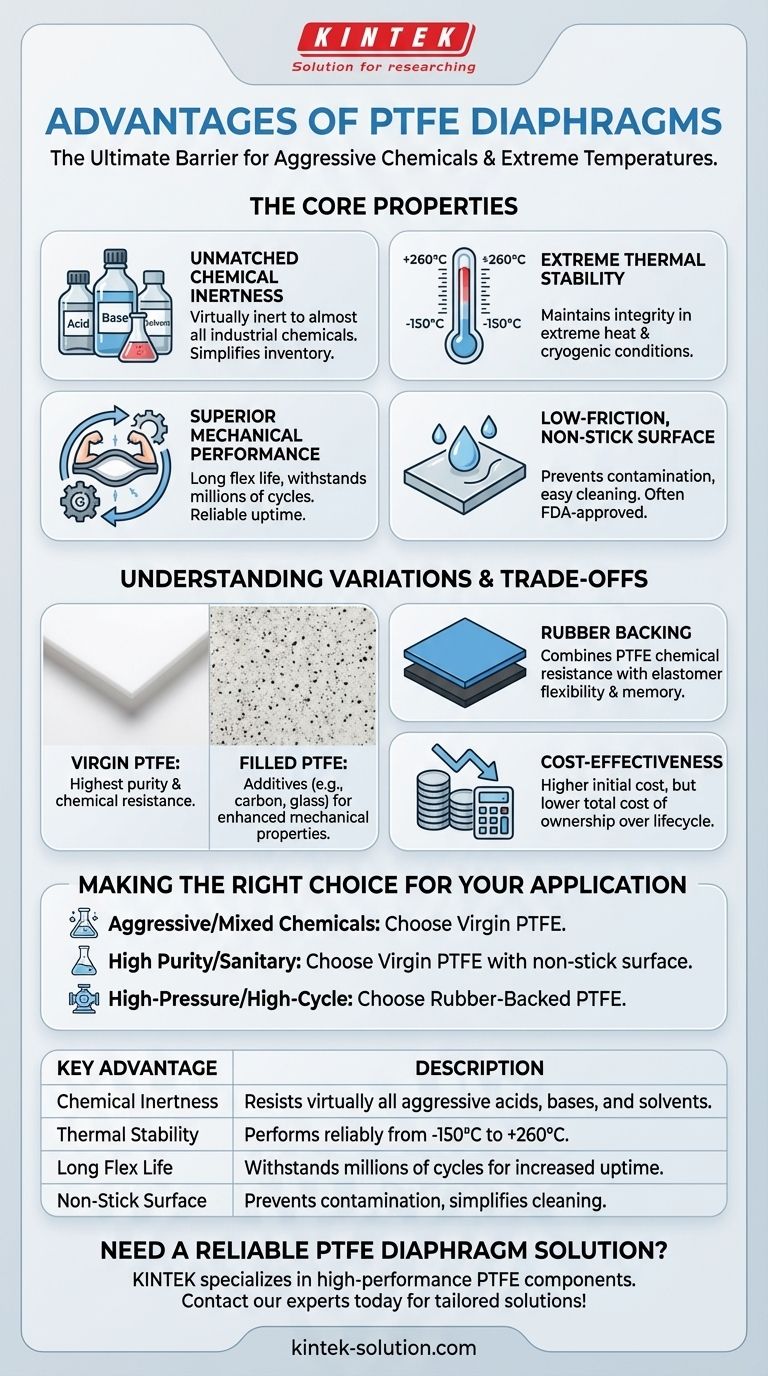

The Core Properties Driving PTFE's Advantages

The benefits of Polytetrafluoroethylene (PTFE) are not arbitrary; they stem directly from its fundamental material properties. Understanding these properties is key to knowing why and where to use it.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals, including aggressive acids, bases, solvents, and oxidizing agents.

This near-universal chemical resistance means you can use a single diaphragm material for a wide variety of process fluids, simplifying inventory and reducing the risk of material failure due to chemical attack.

Extreme Thermal Stability

PTFE diaphragms maintain their integrity and performance across an exceptionally wide temperature range, typically from -150°C to +260°C (-250°F to +500°F).

This allows them to function reliably in applications involving extreme heat or cryogenic conditions where most elastomers would become brittle or melt.

Superior Mechanical Performance

A key advantage of modern PTFE diaphragms is their long flex life. They are designed to withstand millions of cycles without cracking or failing, directly contributing to longer service intervals and increased equipment uptime.

They can be used as a standalone barrier or bonded to a rubber backing, which combines the chemical resistance of PTFE with the flexibility and memory of an elastomer for even greater strength.

Low-Friction, Non-Stick Surface

PTFE has one of the lowest coefficients of friction of any solid material, creating a non-adhesive surface.

This property is critical in sanitary applications, as it resists the buildup of process media and prevents contamination. It also makes cleaning processes faster and more effective, a significant benefit in food-grade and pharmaceutical systems where PTFE is often FDA-approved.

Understanding the Trade-offs and Variations

While PTFE is a high-performance material, selecting the right type and configuration is crucial for optimizing performance and cost. It is not a one-size-fits-all solution.

Virgin PTFE vs. Filled PTFE

Virgin PTFE offers the highest chemical resistance and purity. However, materials can be added to create filled PTFE composites.

Fillers like carbon or glass can enhance specific mechanical properties such as wear resistance and dimensional stability. The trade-off is a potential, though often minor, reduction in universal chemical resistance depending on the filler used.

The Role of a Rubber Backing

While PTFE has excellent flex life, it is not a true elastomer and lacks the "memory" or elasticity of rubber.

In many high-pressure pump and valve applications, a PTFE diaphragm is bonded to a rubber backing. This design leverages the PTFE for chemical exposure while the rubber provides the flexibility and resilience needed to create a consistent, leak-proof seal cycle after cycle.

Cost-Effectiveness vs. Upfront Cost

PTFE often has the best price-to-performance ratio for demanding applications.

While its initial cost may be higher than some standard elastomers, its long life, low maintenance requirements, and ability to prevent failures in harsh environments result in a significantly lower total cost of ownership over the equipment's lifecycle.

Making the Right Choice for Your Application

Selecting the correct diaphragm depends entirely on the primary demands of your system.

- If your primary focus is handling aggressive or mixed chemicals: PTFE is the safest and most reliable choice due to its near-universal chemical inertness.

- If your primary focus is ensuring high purity or sanitary conditions: The non-stick, FDA-compliant surface of virgin PTFE prevents contamination and simplifies cleaning protocols.

- If your primary focus is maximizing durability in high-pressure or high-cycle applications: A rubber-backed PTFE diaphragm offers the ideal combination of chemical resistance and mechanical resilience.

Ultimately, specifying a PTFE diaphragm is a strategic decision for reliability in your most mission-critical applications.

Summary Table:

| Key Advantage | Description |

|---|---|

| Chemical Inertness | Resists virtually all aggressive acids, bases, and solvents. |

| Thermal Stability | Performs reliably from -150°C to +260°C (-250°F to +500°F). |

| Long Flex Life | Withstands millions of cycles for increased equipment uptime. |

| Non-Stick Surface | Prevents contamination and simplifies cleaning in sanitary applications. |

Need a reliable PTFE diaphragm solution for your demanding application?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom diaphragms, seals, liners, and labware. We serve the semiconductor, medical, laboratory, and industrial sectors, ensuring your equipment operates safely and efficiently in the harshest conditions. From prototypes to high-volume orders, our expertise delivers the durability and chemical resistance you require.

Contact our experts today to discuss your specific needs and receive a tailored solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the future trends for PTFE sheets in industrial innovation? From Commodity to Custom-Engineered Solutions

- What is the first step in installing a PTFE gasket? Ensure a Perfect, Leak-Free Seal

- What properties can ceramics provide in PTFE-based laminates? Enhance Thermal, Mechanical & Electrical Performance

- What industries commonly use PTFE-lined valves? Essential for Corrosive & High-Purity Applications

- What is the purpose of PTFE gasket sealing material in mechanical equipment? Enhance Reliability and Efficiency

- What industries benefit from the high-temperature and high-pressure resistance of PTFE bellows? Ensure System Integrity in Demanding Applications

- What unique feature does the PTFE oil seal have for fluid retention? Active Hydrodynamic Sealing Explained

- What are the minimum and maximum sizes for machining PTFE parts? Design for Success with No Universal Limits