At its core, the advantage of using multi-axis CNC machines for PTFE is their ability to produce highly complex parts with superior accuracy and efficiency in a single operation. This approach minimizes part handling, which is critical when working with a soft, low-friction material like Polytetrafluoroethylene (PTFE).

The fundamental challenge with machining PTFE is its softness; it can deform easily under pressure. Multi-axis CNC machining directly solves this by completing intricate geometries in a single setup, drastically reducing the risk of error and unlocking the material's full potential for precision components.

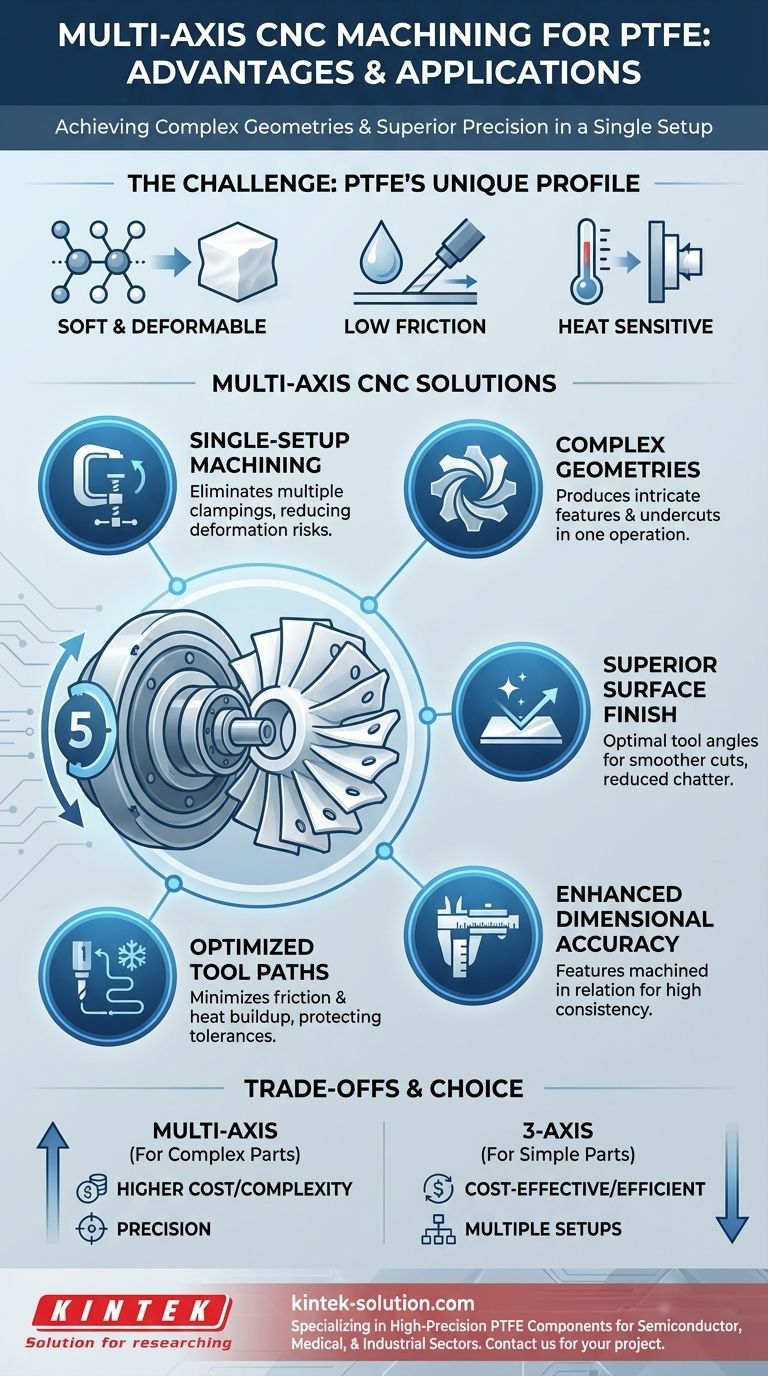

The Challenge: PTFE's Unique Machining Profile

Before understanding the advantages of a specific machine, we must first understand the material itself. PTFE's properties make it highly desirable for many applications but also present unique challenges during machining.

High Machinability, Low Rigidity

PTFE is very easy to cut, a property known as high machinability. However, it is also a soft material with low rigidity, meaning it can easily deform, compress, or warp under the pressure of clamping or cutting tools.

Low Coefficient of Friction

The characteristic slipperiness of PTFE is one of its greatest assets in end-use applications like bearings. During machining, this low friction requires extremely sharp tools to ensure the material is cut cleanly rather than being pushed or smeared.

Sensitivity to Heat Buildup

While PTFE has high-temperature resistance, excessive heat generated by tool friction during machining can cause it to expand or deform. This can compromise the dimensional accuracy of the final part if not managed properly.

How Multi-Axis Machining Solves These Challenges

A multi-axis CNC machine (often 4-axis or 5-axis) can move a tool or the workpiece along multiple rotational and linear axes simultaneously. This capability directly addresses the core challenges of machining PTFE.

Enabling Complex Geometries in a Single Clamping

This is the most significant advantage. A 3-axis machine often requires the operator to unclamp, rotate, and re-clamp the part to access different faces. Each re-clamping of a soft material like PTFE introduces a potential for deformation and misalignment.

A multi-axis machine can rotate the part or the tool head to reach nearly any angle, allowing it to complete all machining operations in a single setup. This drastically improves precision for parts with complex curves, undercuts, and angled holes.

Achieving Superior Surface Finishes

Because the tool can approach the workpiece from optimal angles, multi-axis machines can maintain ideal cutting conditions across the entire part surface. This continuous, optimized tool path reduces chatter and tool marks, resulting in a smoother, higher-quality finish.

Enhancing Dimensional Accuracy and Consistency

By eliminating multiple setups, you eliminate the primary source of operator error and tolerance stacking. The part's features are all machined in relation to each other in one continuous operation, ensuring the highest possible dimensional accuracy and part-to-part consistency.

Optimizing Tool Paths and Speeds

Advanced tool paths on a multi-axis machine allow for smoother engagement with the material. This can reduce friction and heat buildup, preventing the thermal expansion that can ruin the tolerances of a finished PTFE part.

Understanding the Trade-offs

While powerful, a multi-axis approach is not always the default solution. Objectivity requires acknowledging its specific context and costs.

Higher Initial and Operational Cost

Multi-axis CNC machines are significantly more expensive than their 3-axis counterparts. The cost per hour for machine time is therefore higher, which can impact the final price of the component.

Increased Programming Complexity

Creating the toolpaths for 5-axis machining requires specialized CAM software and highly skilled programmers and operators. This added complexity can increase lead times and setup costs for the first run of a new part.

Not Always Necessary for Simple Parts

For geometrically simple PTFE parts, such as flat gaskets, simple washers, or basic bushings, a 3-axis machine is often perfectly sufficient and far more cost-effective. Using a multi-axis machine for these components would be inefficient.

Making the Right Choice for Your PTFE Component

Your decision should be driven entirely by the requirements of the final part.

- If your primary focus is intricate parts with undercuts, curved surfaces, or angled features: Multi-axis machining is the only way to achieve the necessary geometry and precision reliably.

- If your primary focus is cost-effectiveness for high-volume, simple parts: A traditional 3-axis CNC process is almost always the more economical and efficient choice.

- If your primary focus is achieving the absolute highest dimensional accuracy and flawless surface finish: Multi-axis machining is superior due to its single-setup capability, which eliminates the tolerance errors inherent in multiple clampings.

Ultimately, choosing the right manufacturing process is about aligning the machine's capability with the material's properties to meet your design's intent.

Summary Table:

| Advantage | Description |

|---|---|

| Single-Setup Machining | Eliminates multiple clampings, reducing deformation and misalignment risks for soft PTFE. |

| Complex Geometries | Enables production of intricate parts with undercuts, curves, and angled features in one operation. |

| Superior Surface Finish | Maintains optimal tool angles for smoother cuts, reducing chatter and tool marks. |

| Enhanced Dimensional Accuracy | Features are machined in relation to each other in one setup, ensuring high consistency. |

| Reduced Heat Buildup | Optimized tool paths minimize friction and thermal expansion, protecting part tolerances. |

Need a precision PTFE component with complex geometries?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, and industrial sectors. Our advanced multi-axis CNC capabilities ensure your soft, low-friction PTFE parts are produced with exceptional accuracy and flawless surface finishes, all in a single setup to minimize handling risks.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision to meet your most demanding specifications.

Contact us today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications