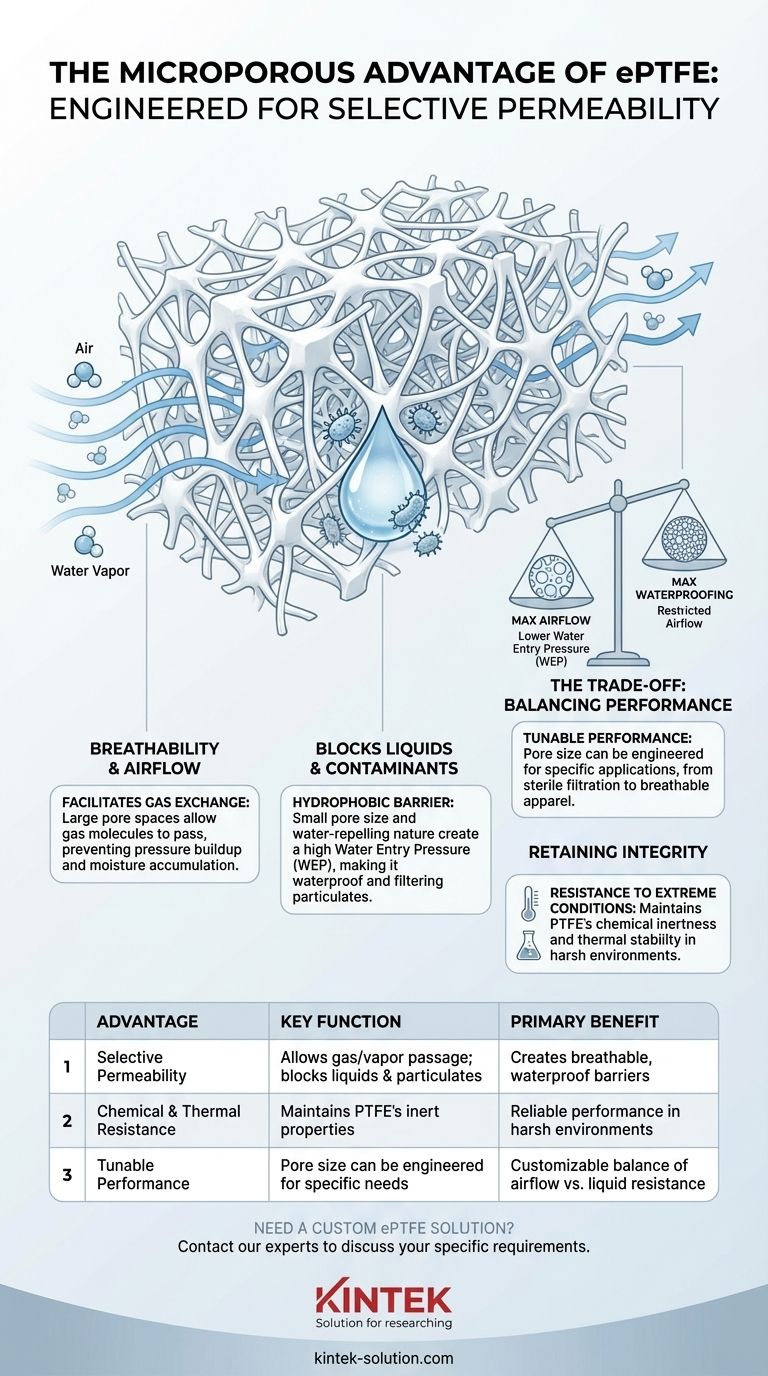

At its core, the advantage of ePTFE's microporous structure is its ability to function as a highly selective barrier. This structure, a complex web of nodes and fibrils, allows gases like air and water vapor to pass through easily while simultaneously blocking the penetration of liquids and fine particulates like microbes.

The true power of ePTFE's microporous nature lies in its engineered paradox: it is simultaneously breathable and waterproof. This unique combination of properties makes it exceptionally versatile for demanding applications in medicine, industry, and consumer products.

The Core Principle: Selective Permeability

Expanded Polytetrafluoroethylene (ePTFE) is created by stretching PTFE, which transforms the solid material into a microporous membrane. This structure is not a simple collection of holes but an intricate network of solid PTFE nodes connected by extremely thin fibrils. The functionality stems from the size of the pores created between these fibrils.

Facilitating Airflow and Gas Exchange

The spaces between the fibrils are large enough for gas molecules to move through with minimal resistance. This property is often referred to as air permeability or breathability.

This is critical for applications that require venting or the release of water vapor, preventing pressure buildup or moisture accumulation within a sealed enclosure.

Blocking Liquids and Contaminants

While porous to gases, the structure is a formidable barrier to liquids. This is due to a combination of small pore size and the hydrophobic (water-repelling) nature of PTFE.

This combination creates a high Water Entry Pressure (WEP). Water droplets cannot overcome the surface tension to penetrate the small pores, effectively making the material waterproof.

Furthermore, these pores are small enough to act as a physical barrier, trapping microbes and other particulate matter, which is essential for filtration and sterile medical applications.

Retaining Material Integrity

The expansion process maintains the exceptional inherent properties of the base PTFE material. The resulting ePTFE membrane remains highly resistant to both extreme temperatures and a wide range of aggressive chemicals.

This ensures the material can perform its barrier function reliably in harsh operating environments where other materials would quickly degrade.

Understanding the Trade-offs

The advantages of ePTFE are not absolute; they are part of an engineered balance. Understanding this relationship is key to specifying the material correctly for a given application.

The Airflow vs. Water Resistance Balance

There is a direct trade-off between airflow and water resistance. A structure engineered for maximum airflow will have larger pores, which inherently lowers its Water Entry Pressure.

Conversely, an ePTFE membrane designed for the highest level of waterproofing will have very small pores, which will restrict airflow. The specific application dictates where on this spectrum the material must perform.

Impact on Mechanical Strength

The expansion process that creates porosity also reduces the material's density compared to solid PTFE. While ePTFE is remarkably strong for its weight, its mechanical properties, such as tensile strength, can differ from its solid counterpart.

Designers must account for these mechanical characteristics, especially in applications involving high stress or physical wear.

Making the Right Choice for Your Application

The versatility of ePTFE means its structure can be tuned to meet specific performance goals. Your primary objective will determine the ideal material specification.

- If your primary focus is venting or breathability: You will need an ePTFE with a more open pore structure, prioritizing high airflow while accepting a moderate level of water resistance.

- If your primary focus is sterile filtration or absolute waterproofing: You will require a dense ePTFE structure with smaller pores to ensure a high Water Entry Pressure and a reliable barrier to microbes.

- If your primary focus is balanced performance for apparel or electronics: The goal is to find the optimal combination of airflow and water resistance that protects the user or device without trapping moisture.

Ultimately, the microporous structure of ePTFE provides a powerful and adaptable toolkit for solving complex engineering challenges.

Summary Table:

| Advantage | Key Function | Primary Benefit |

|---|---|---|

| Selective Permeability | Allows gas/vapor passage; blocks liquids & particulates | Creates breathable, waterproof barriers |

| Chemical & Thermal Resistance | Maintains PTFE's inert properties | Reliable performance in harsh environments |

| Tunable Performance | Pore size can be engineered for specific needs | Customizable balance of airflow vs. liquid resistance |

Need a custom ePTFE solution for your project?

KINTEK specializes in the precision manufacturing of PTFE and ePTFE components, including seals, liners, and labware. Whether you need a prototype for a new medical device or high-volume production for industrial filtration, we can engineer the microporous structure to meet your exact requirements for breathability, waterproofing, and chemical resistance.

Contact our experts today to discuss how our custom ePTFE fabrication can enhance your product's performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- PTFE Deep Evaporating Dishes Customizable Laboratory and Industrial Solutions

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts